LOCAL/

10:47:45 AM

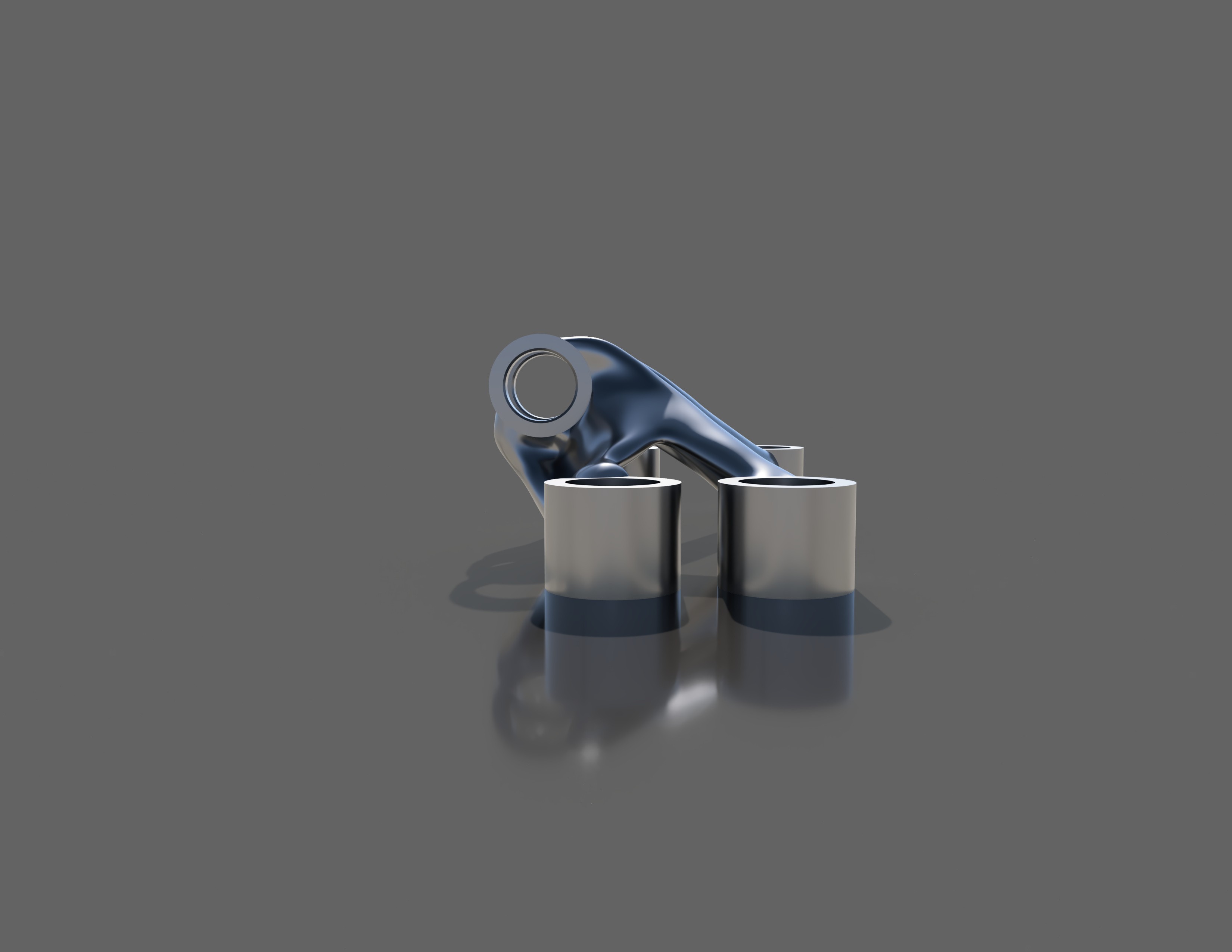

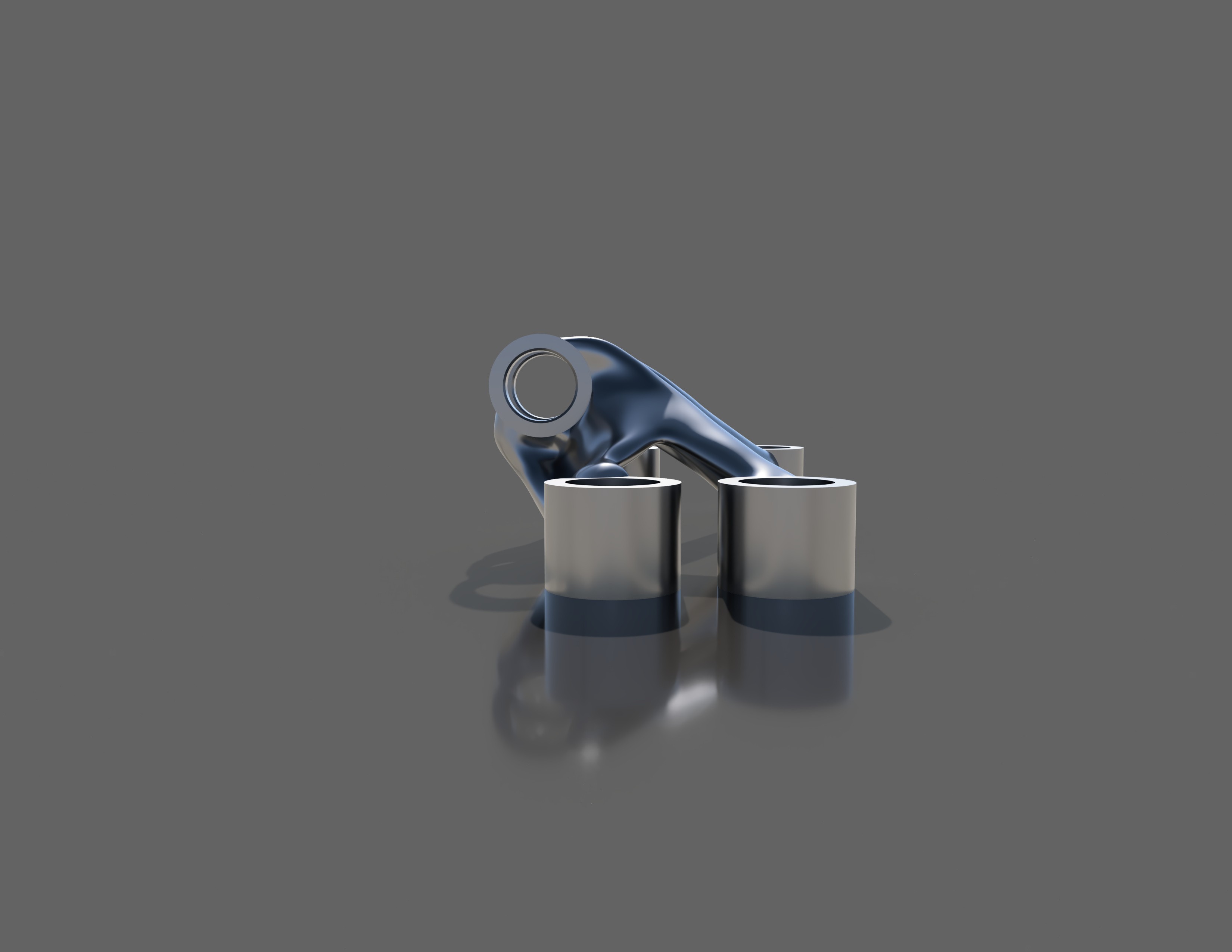

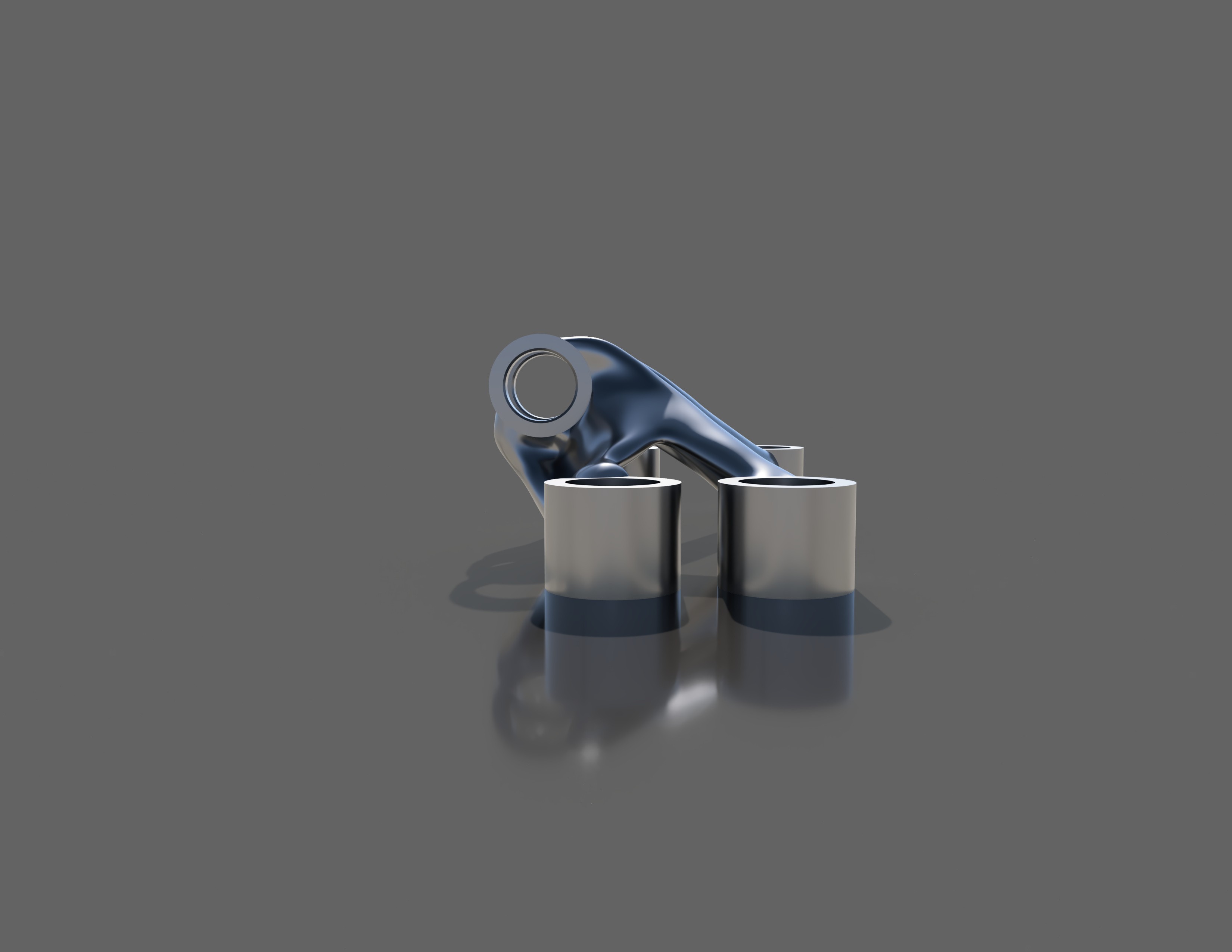

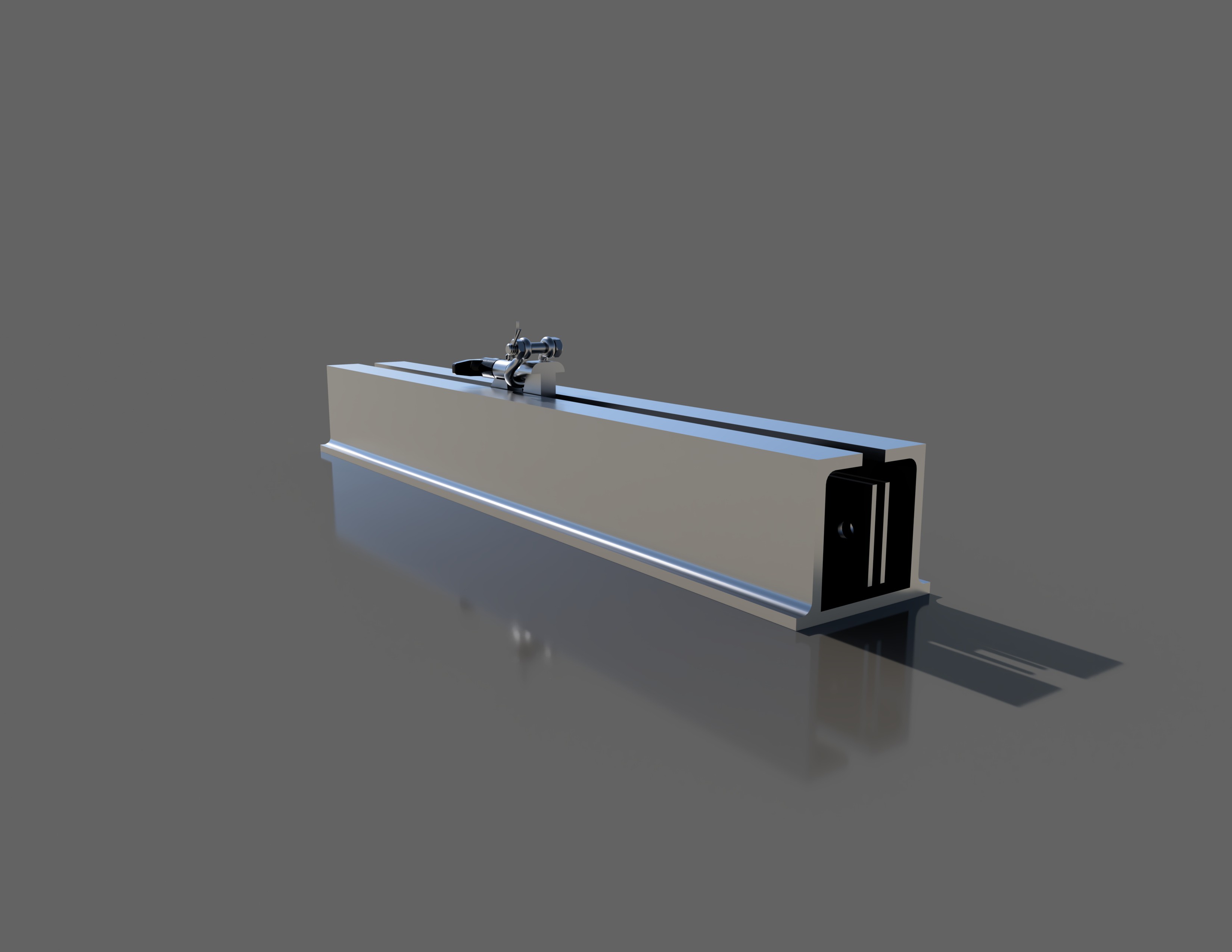

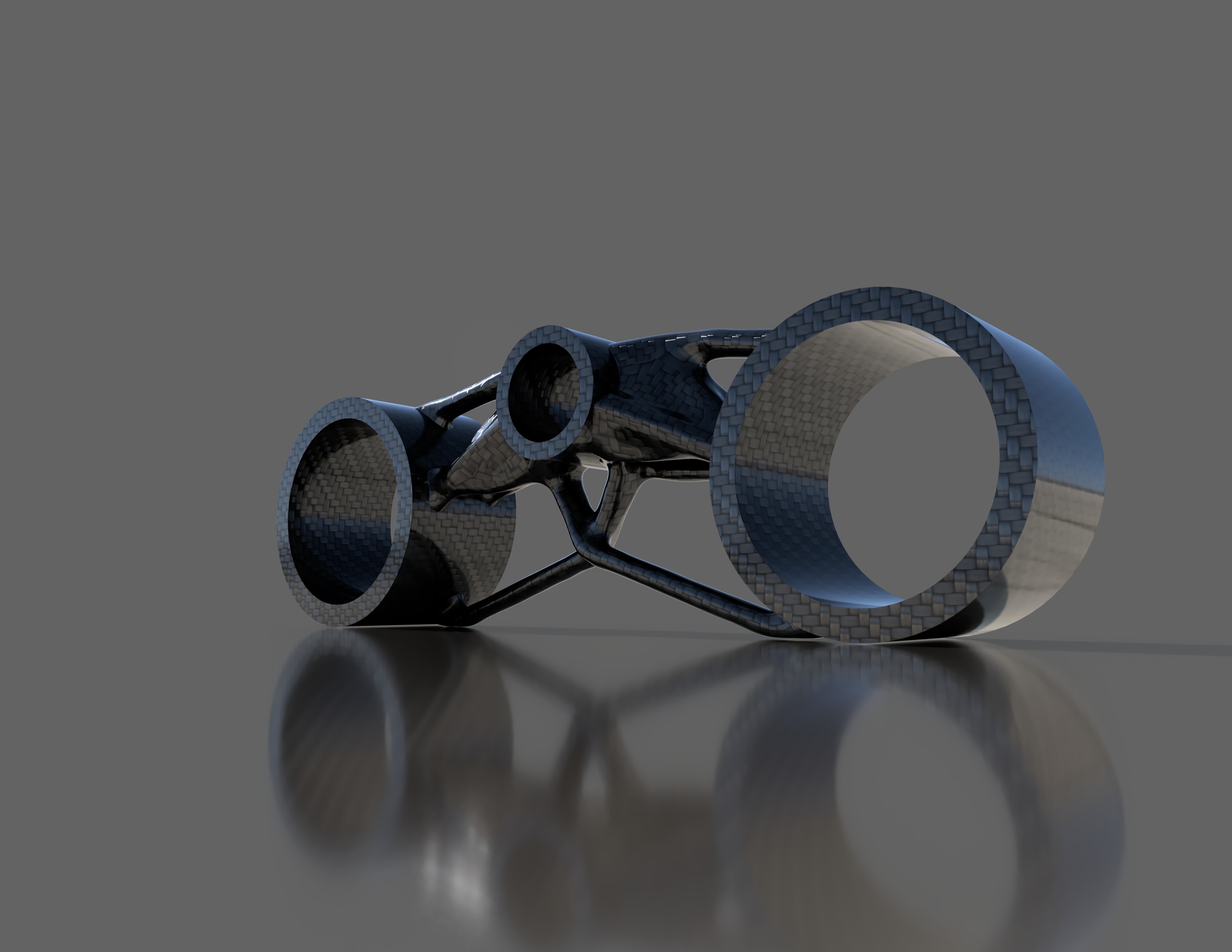

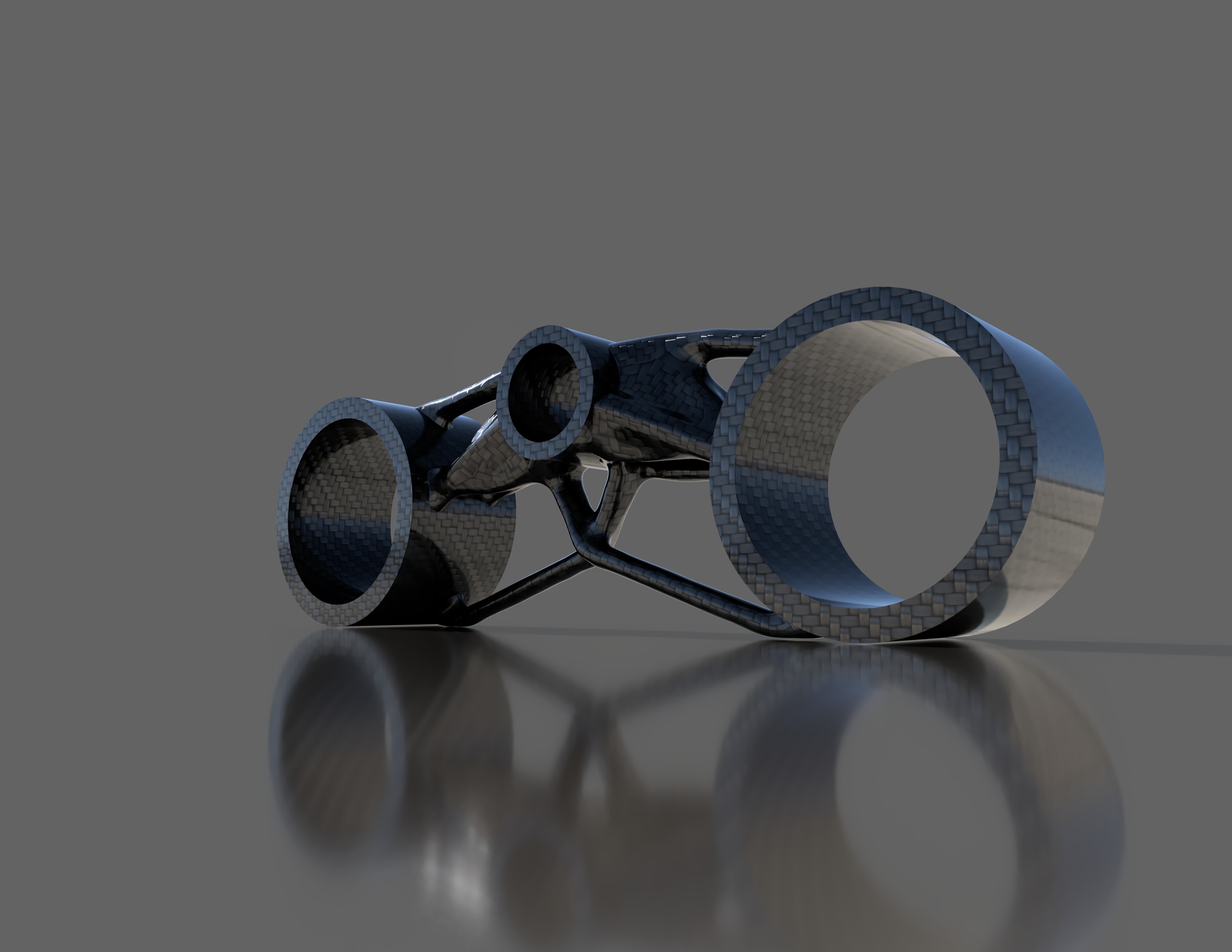

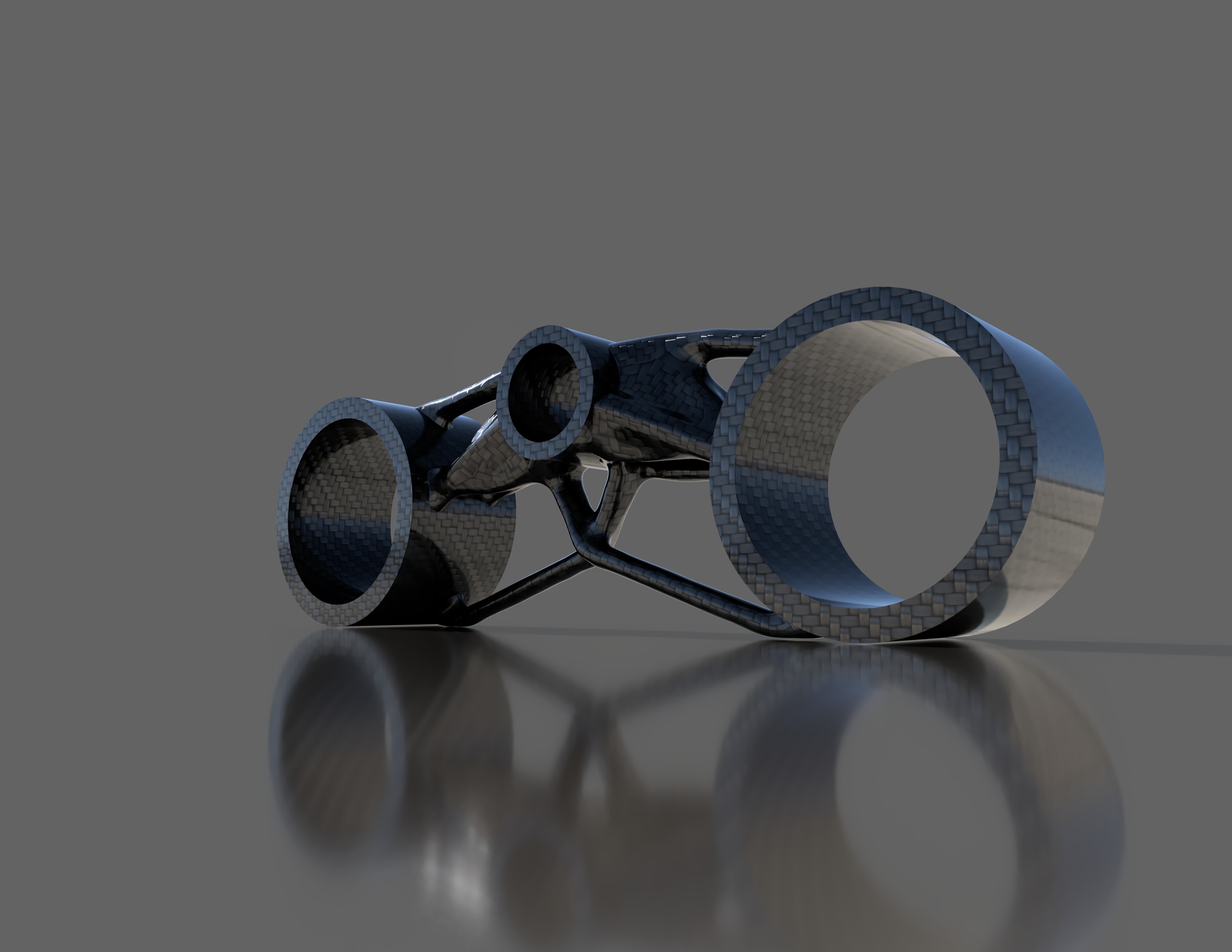

GE Bracket

GE Bracket

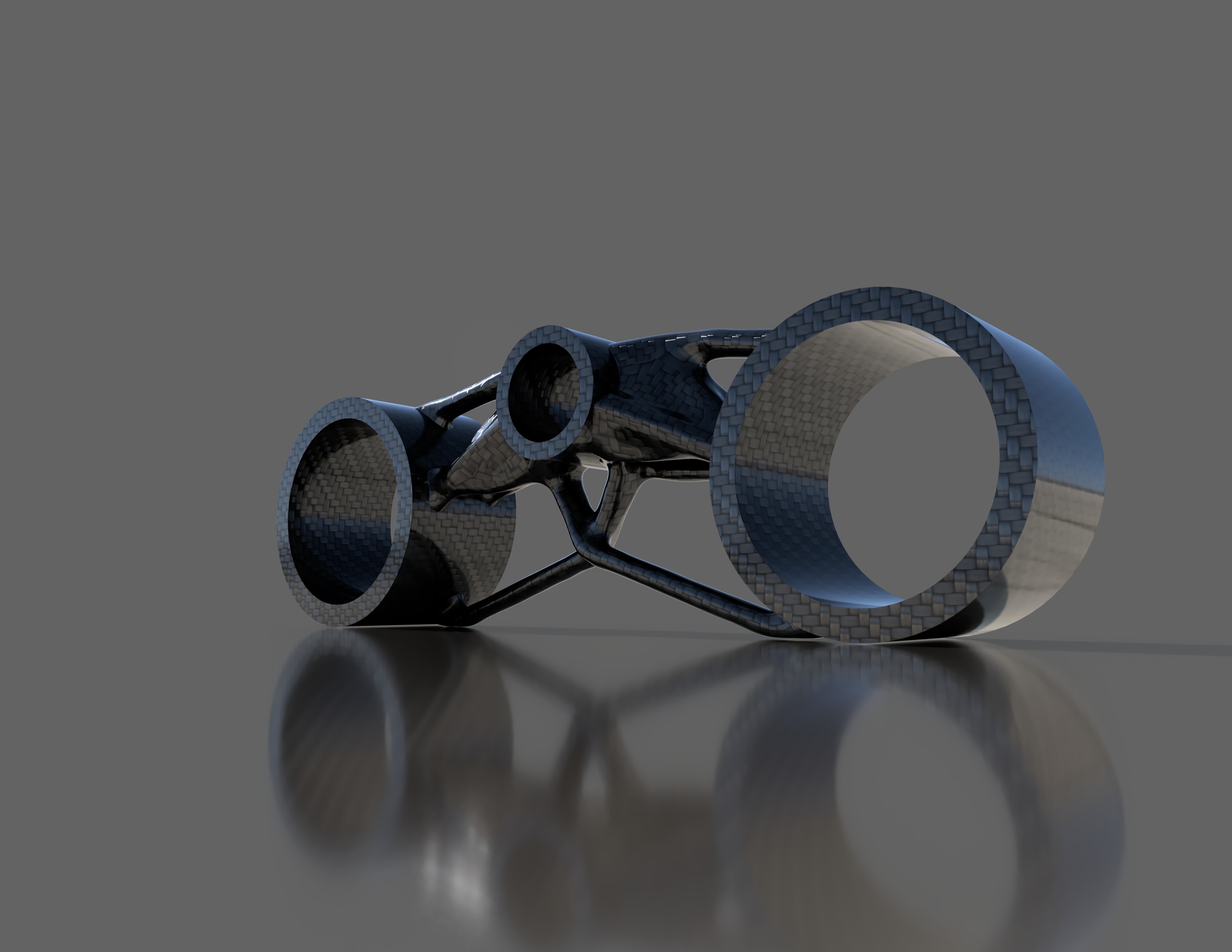

This project involved creating a lightweight bracket using generative design based solely on load cases and mounting conditions. Without a defined end-use, the focus was on exploring structurally efficient forms guided purely by performance constraints.

Duration

2 Months

Year

2025

Category

Generative Design

Research

Research

With no specified application, the design was approached from a purely functional standpoint. Load directions, magnitudes, and mounting constraints were studied to define the problem space. Material properties and safety factors were chosen to ensure structural viability under the given conditions.

With no specified application, the design was approached from a purely functional standpoint. Load directions, magnitudes, and mounting constraints were studied to define the problem space. Material properties and safety factors were chosen to ensure structural viability under the given conditions.

Research

With no specified application, the design was approached from a purely functional standpoint. Load directions, magnitudes, and mounting constraints were studied to define the problem space. Material properties and safety factors were chosen to ensure structural viability under the given conditions.

Design

Design

The process began with defining fixed supports and load inputs in the generative design environment. Multiple iterations were run to explore a range of structurally optimized geometries. The final form balanced minimal material usage with strength, while preserving symmetry and clean load paths.

The process began with defining fixed supports and load inputs in the generative design environment. Multiple iterations were run to explore a range of structurally optimized geometries. The final form balanced minimal material usage with strength, while preserving symmetry and clean load paths.

Design

The process began with defining fixed supports and load inputs in the generative design environment. Multiple iterations were run to explore a range of structurally optimized geometries. The final form balanced minimal material usage with strength, while preserving symmetry and clean load paths.

Development

Development

The final design was exported from the generative tool and refined for 3D printing. Minor adjustments were made to improve printability and structural integrity. Simulations were run to validate performance under defined loads, ensuring the bracket met safety and stiffness criteria.

The final design was exported from the generative tool and refined for 3D printing. Minor adjustments were made to improve printability and structural integrity. Simulations were run to validate performance under defined loads, ensuring the bracket met safety and stiffness criteria.

Development

The final design was exported from the generative tool and refined for 3D printing. Minor adjustments were made to improve printability and structural integrity. Simulations were run to validate performance under defined loads, ensuring the bracket met safety and stiffness criteria.

Concept

Concept

The intent was to explore form purely driven by function, using generative design to eliminate excess material and create an efficient load-bearing structure. With no predefined use, the project served as a study in performance-based design for lightweight components.

The intent was to explore form purely driven by function, using generative design to eliminate excess material and create an efficient load-bearing structure. With no predefined use, the project served as a study in performance-based design for lightweight components.

Concept

The intent was to explore form purely driven by function, using generative design to eliminate excess material and create an efficient load-bearing structure. With no predefined use, the project served as a study in performance-based design for lightweight components.

More Works More Works

More Works More Works

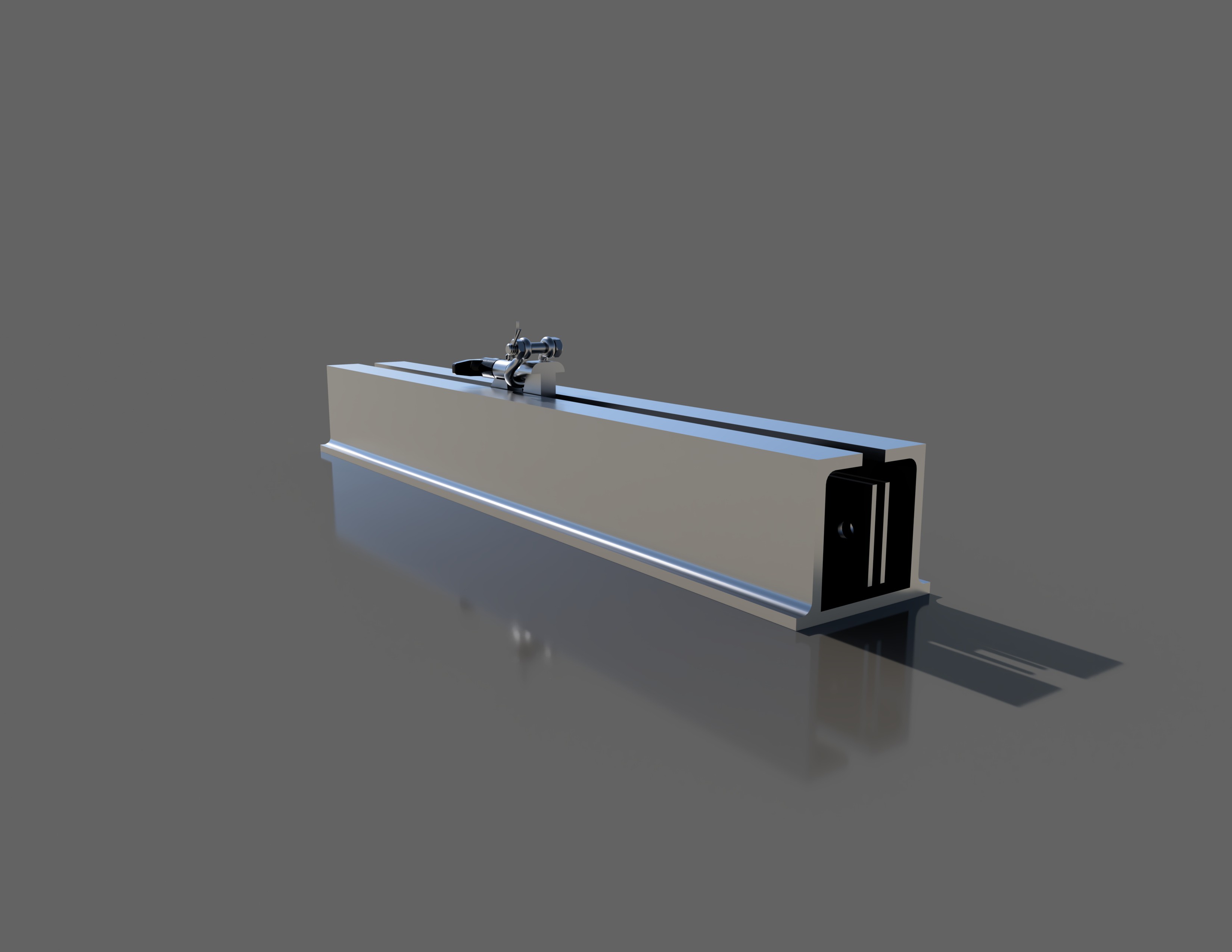

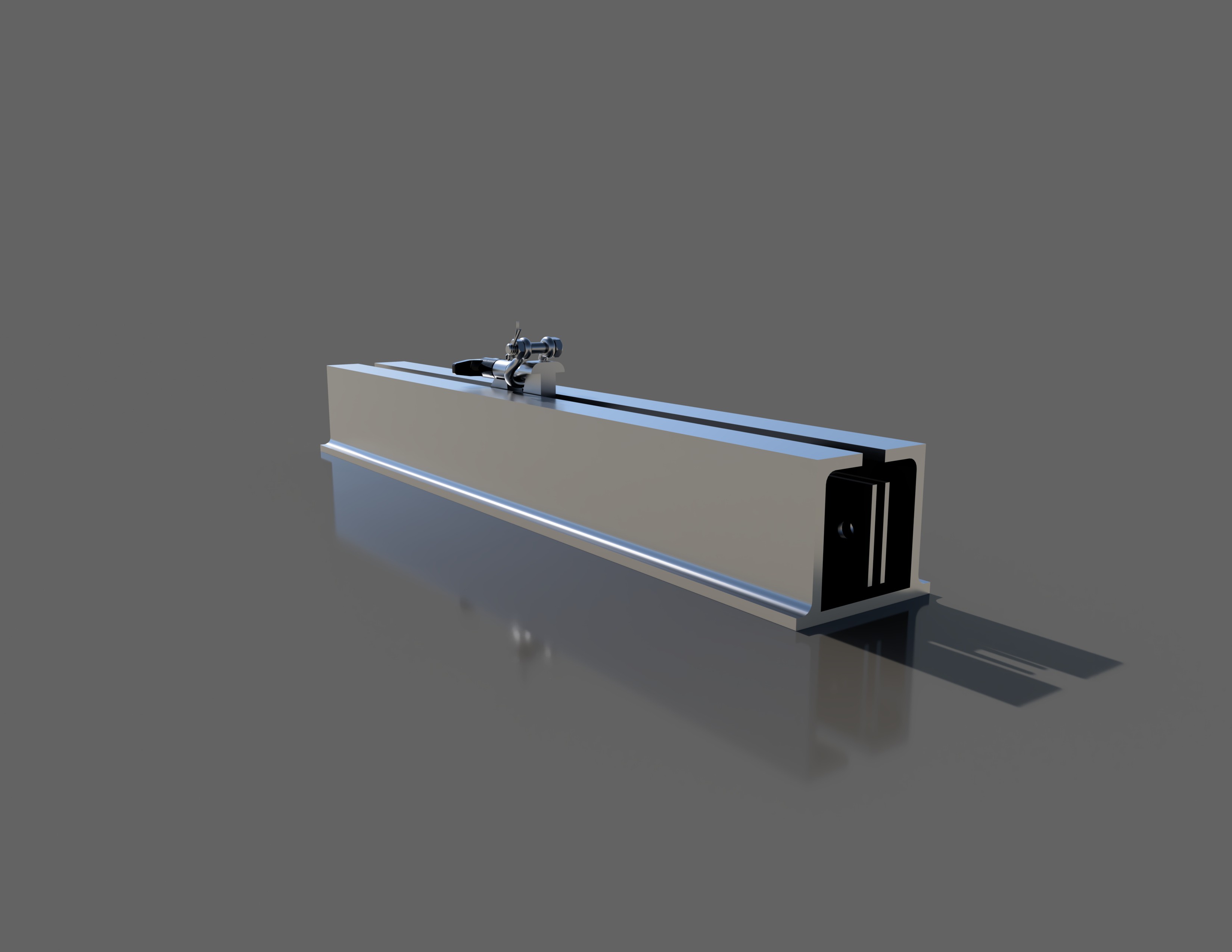

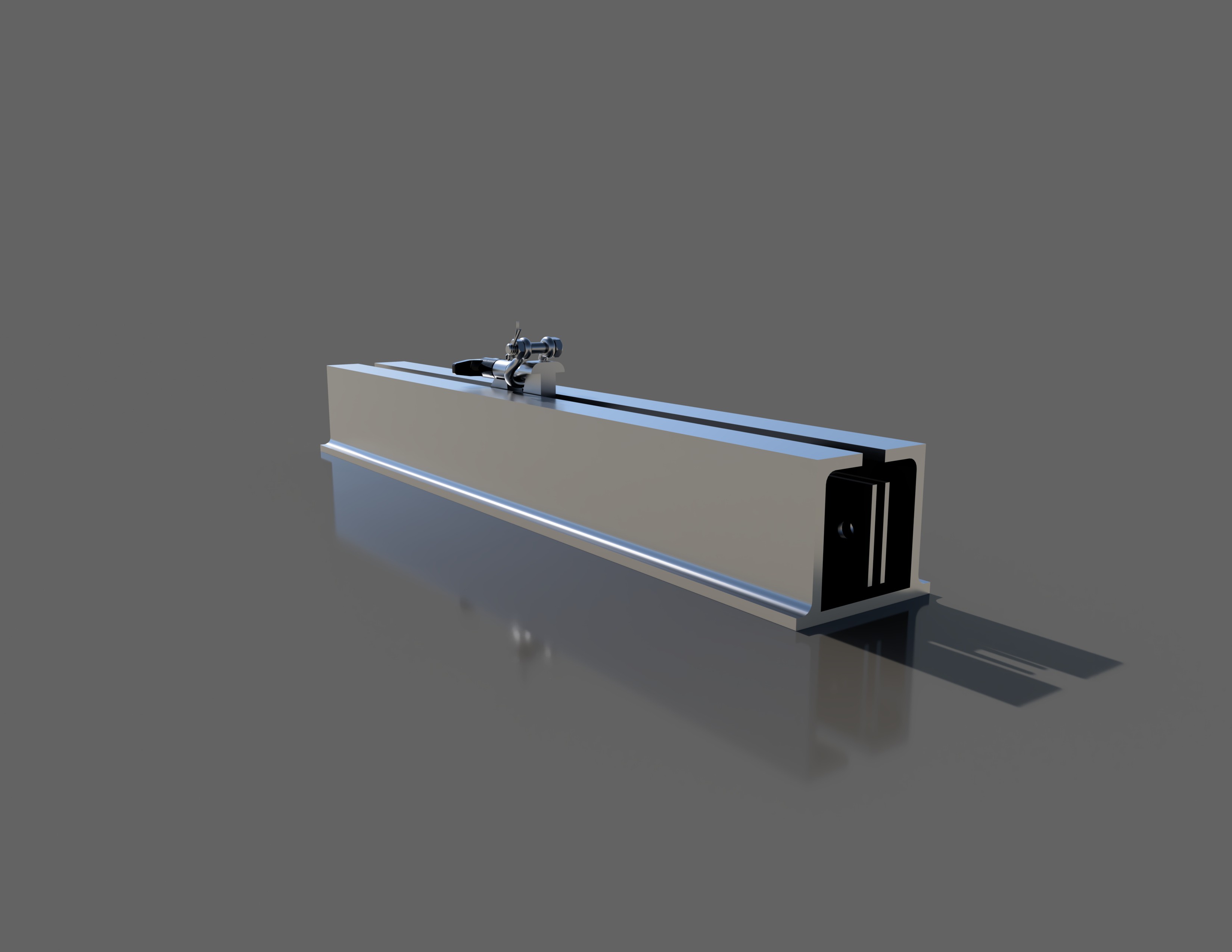

Skate and Rail Assembly

Designing & Simulation

2025

2025

Skate and Rail Assembly

Designing & Simulation

2025

2025

Skate and Rail Assembly

Designing & Simulation

2025

2025

Skate and Rail Assembly

Designing & Simulation

2025

2025

Motorcycle Triple Clamps

Generative Design

2024

2024

Motorcycle Triple Clamps

Generative Design

2024

2024

Motorcycle Triple Clamps

Generative Design

2024

2024

Motorcycle Triple Clamps

Generative Design

2024

2024

©2024 MANDRO DESIGN

GO BACK TO TOP

©2024 MANDRO DESIGN

GO BACK TO TOP