LOCAL/

10:47:45 AM

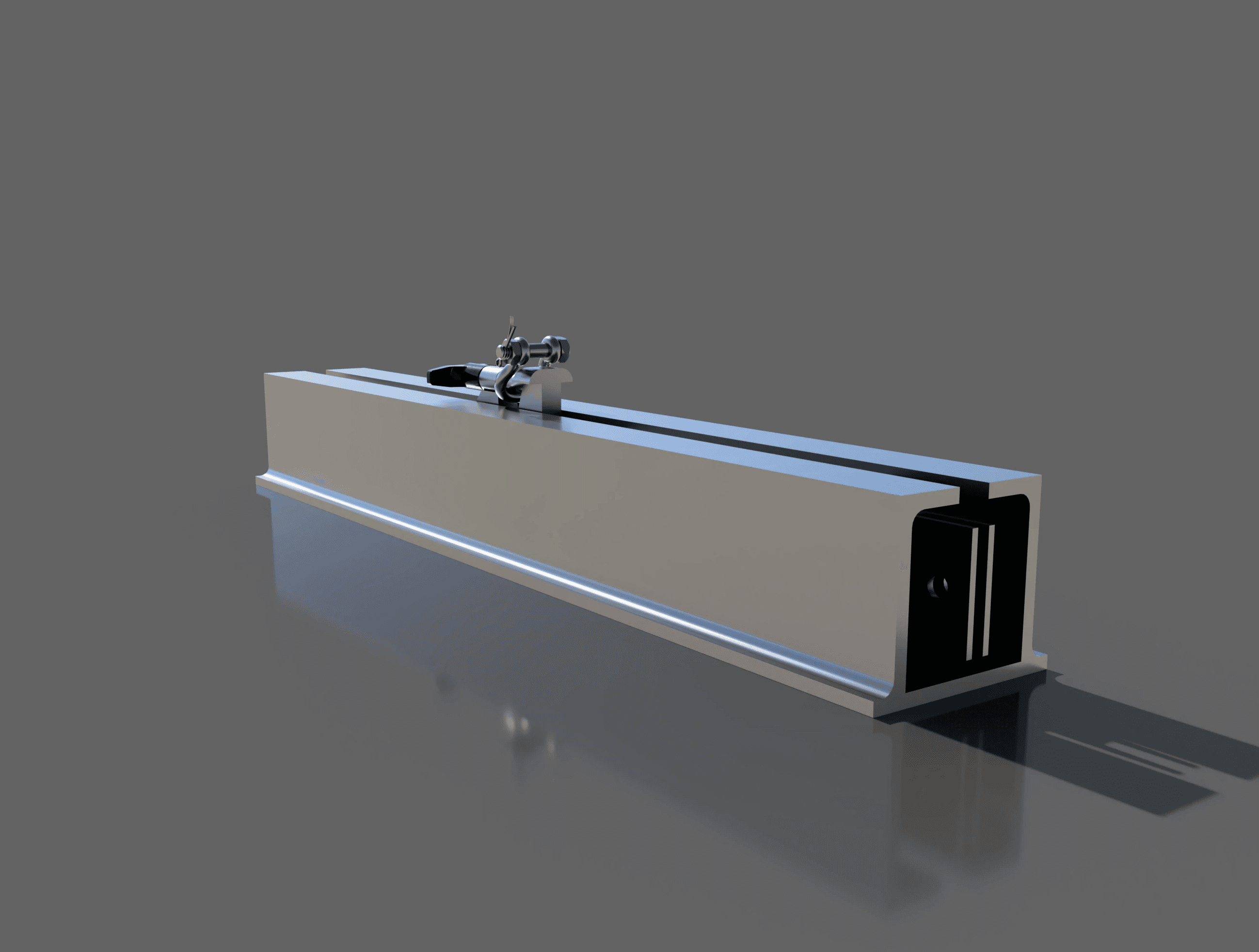

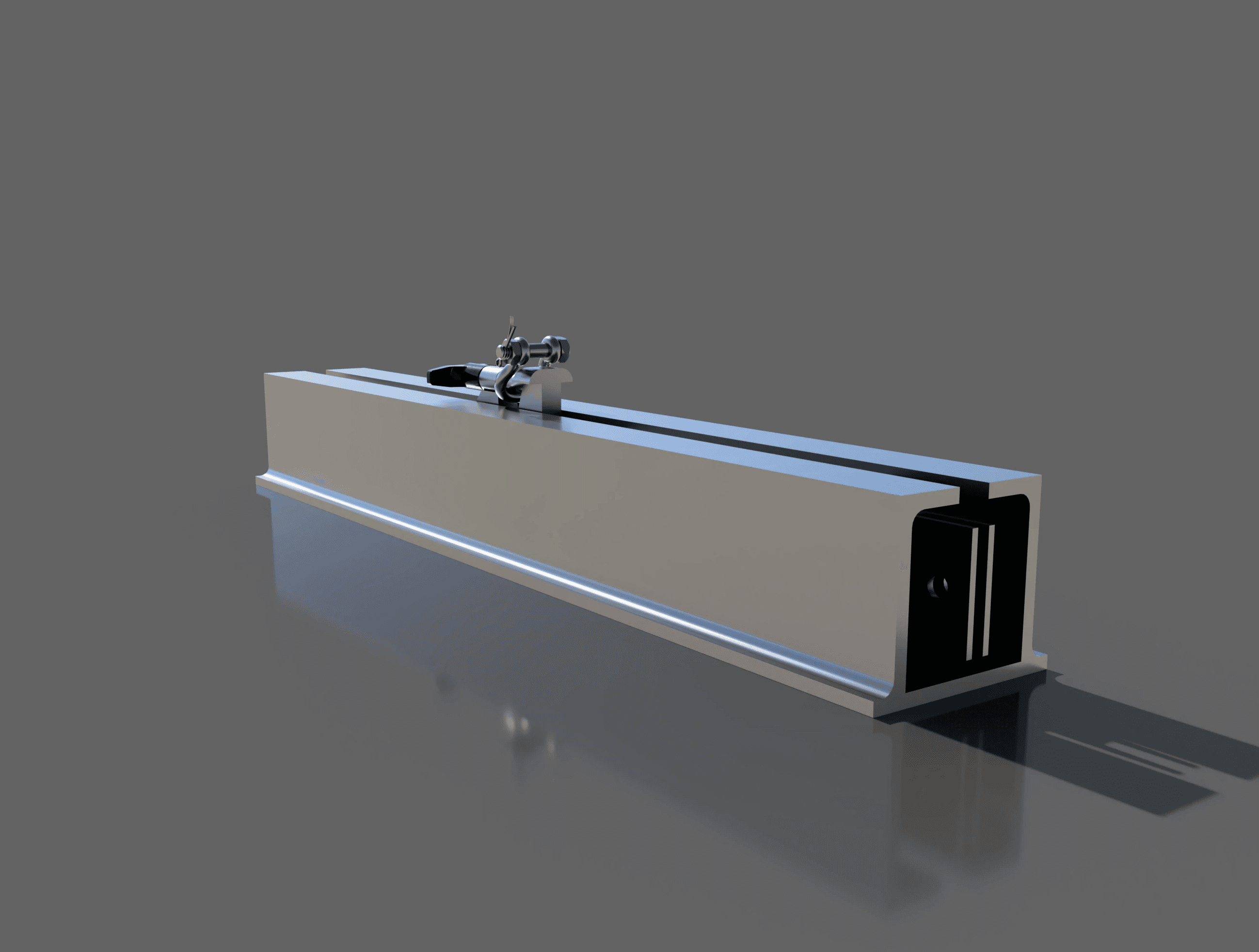

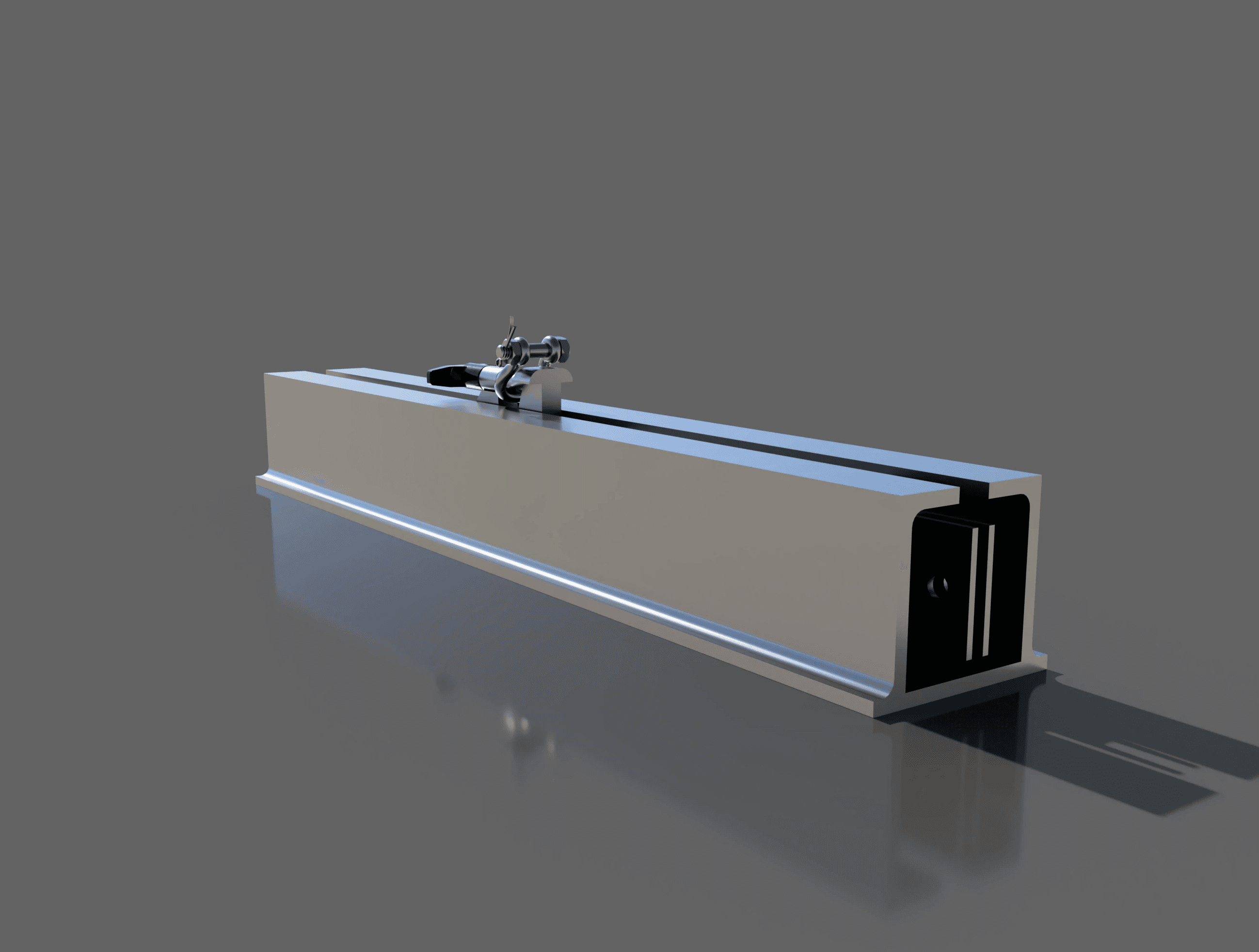

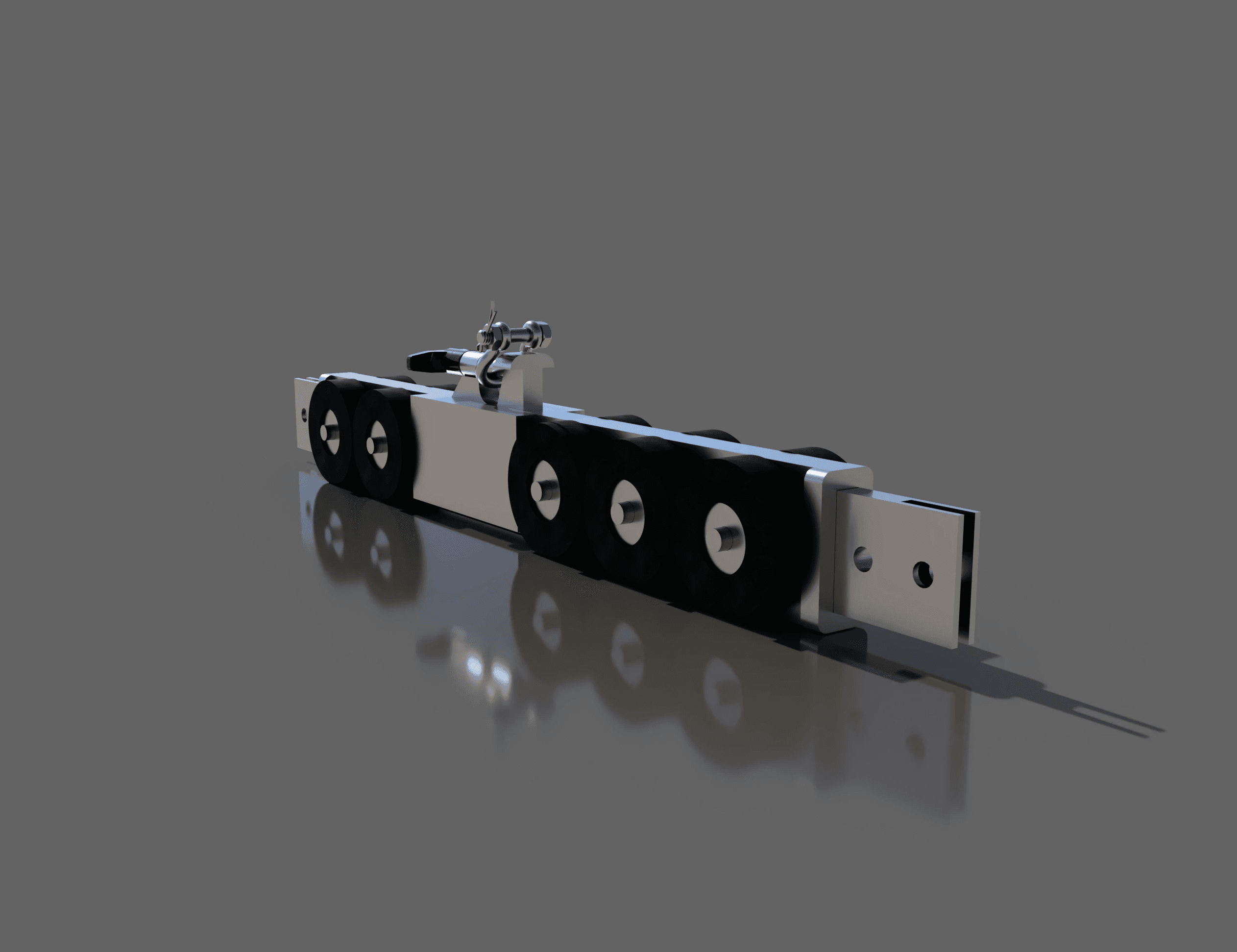

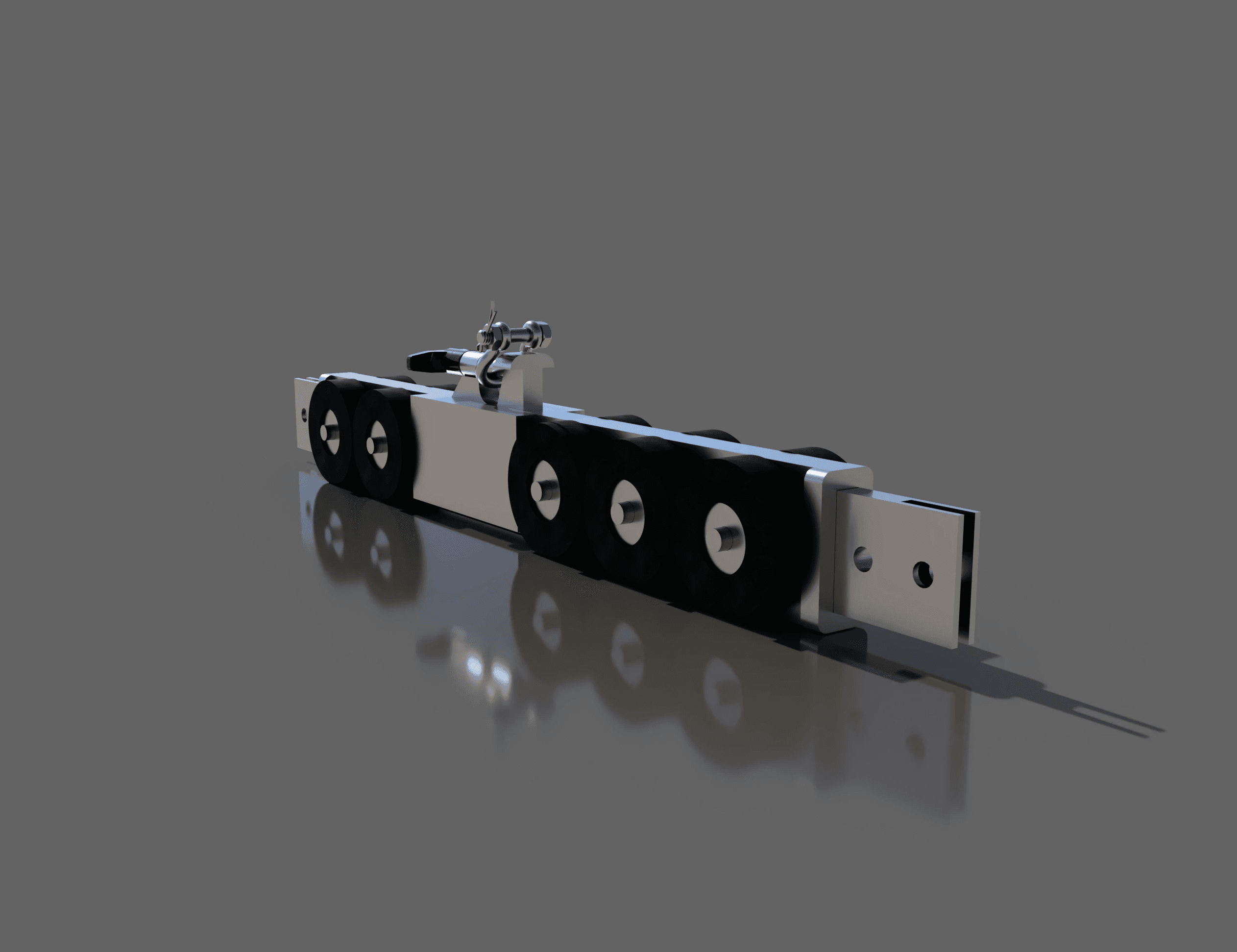

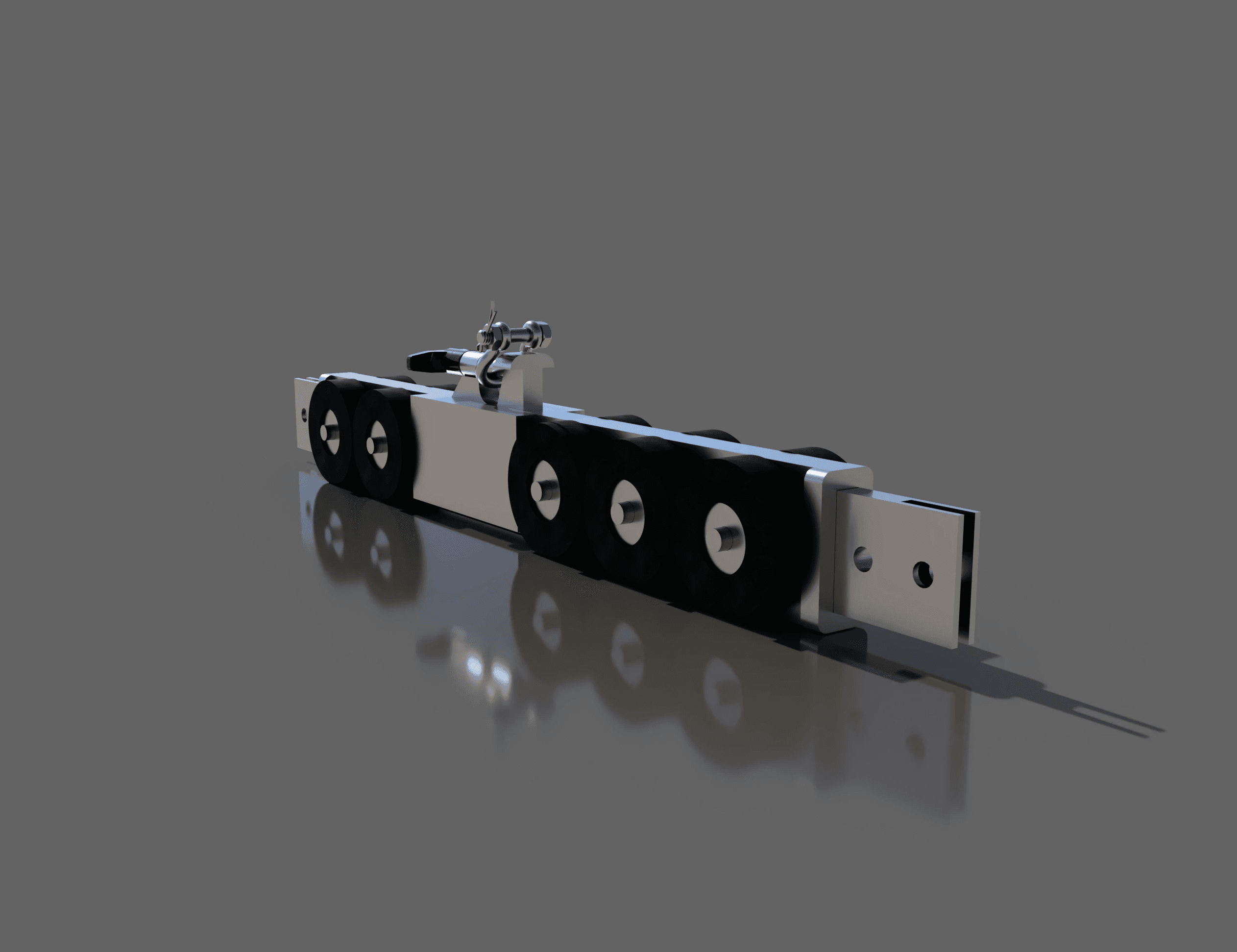

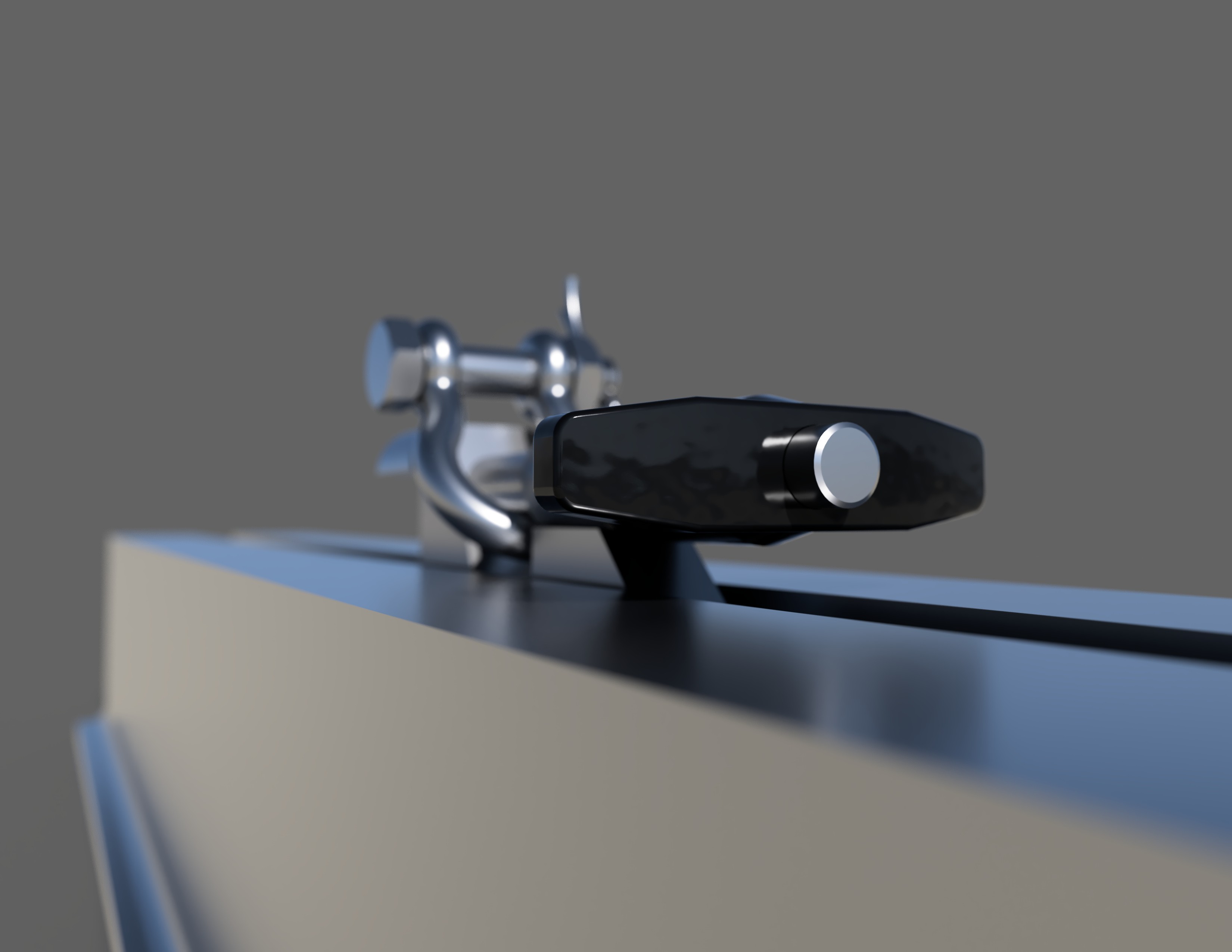

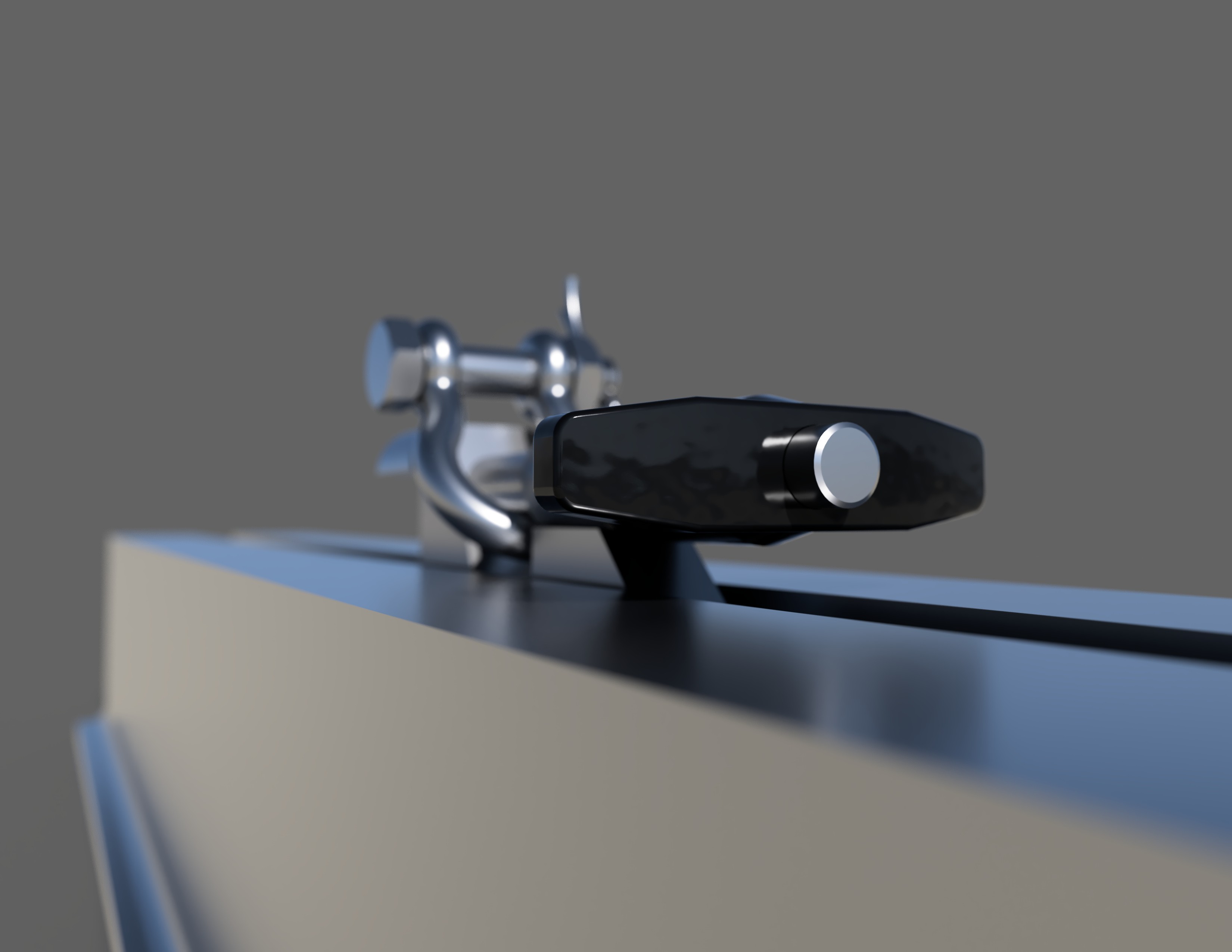

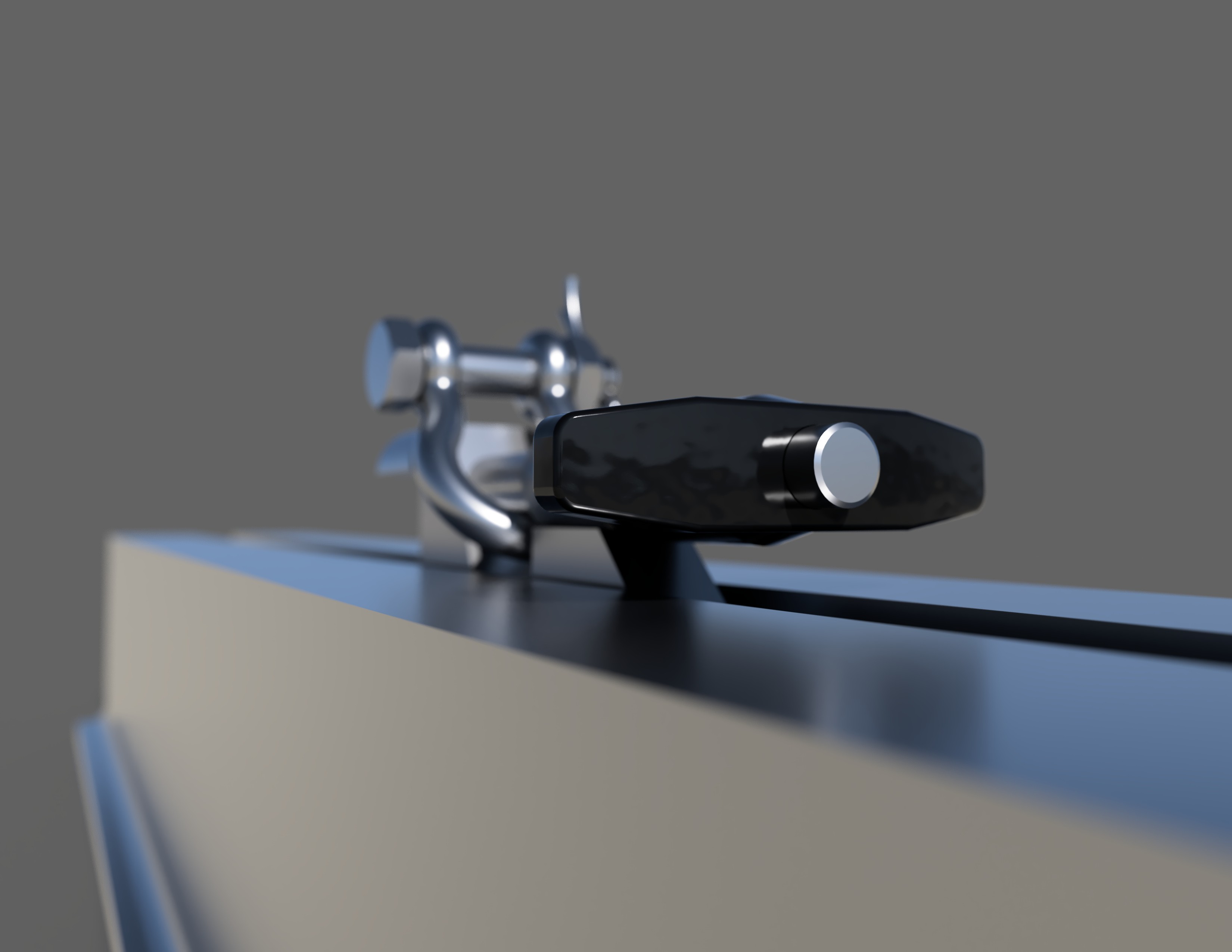

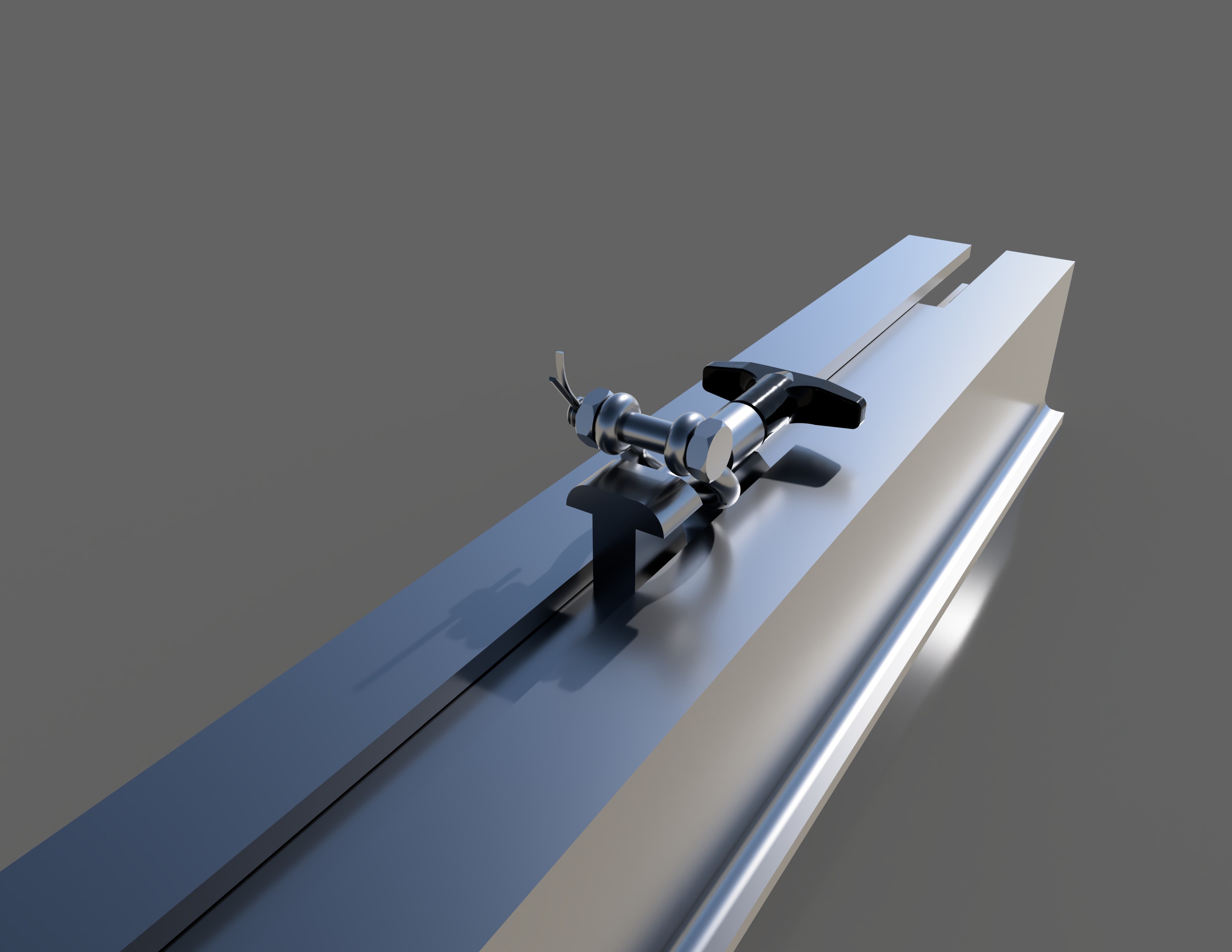

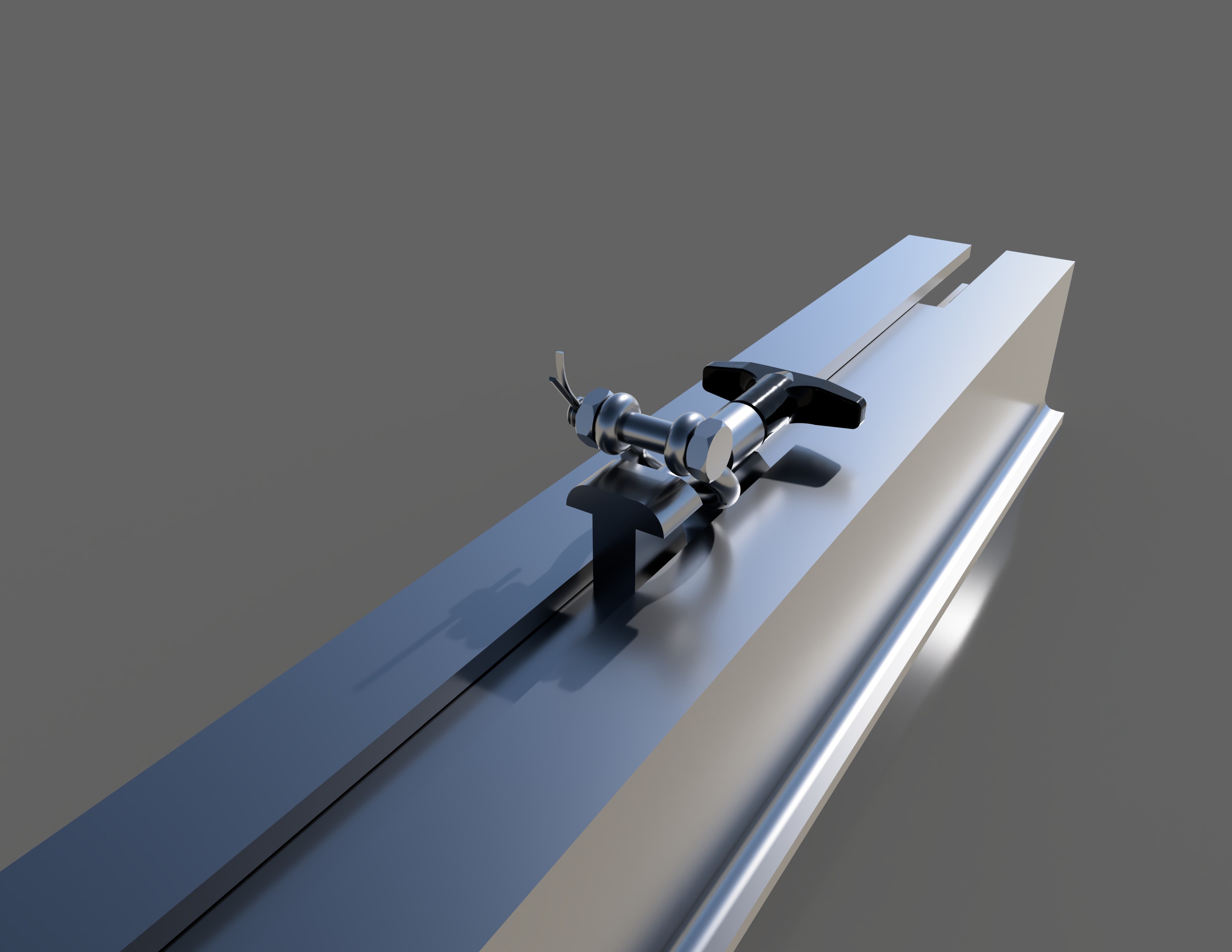

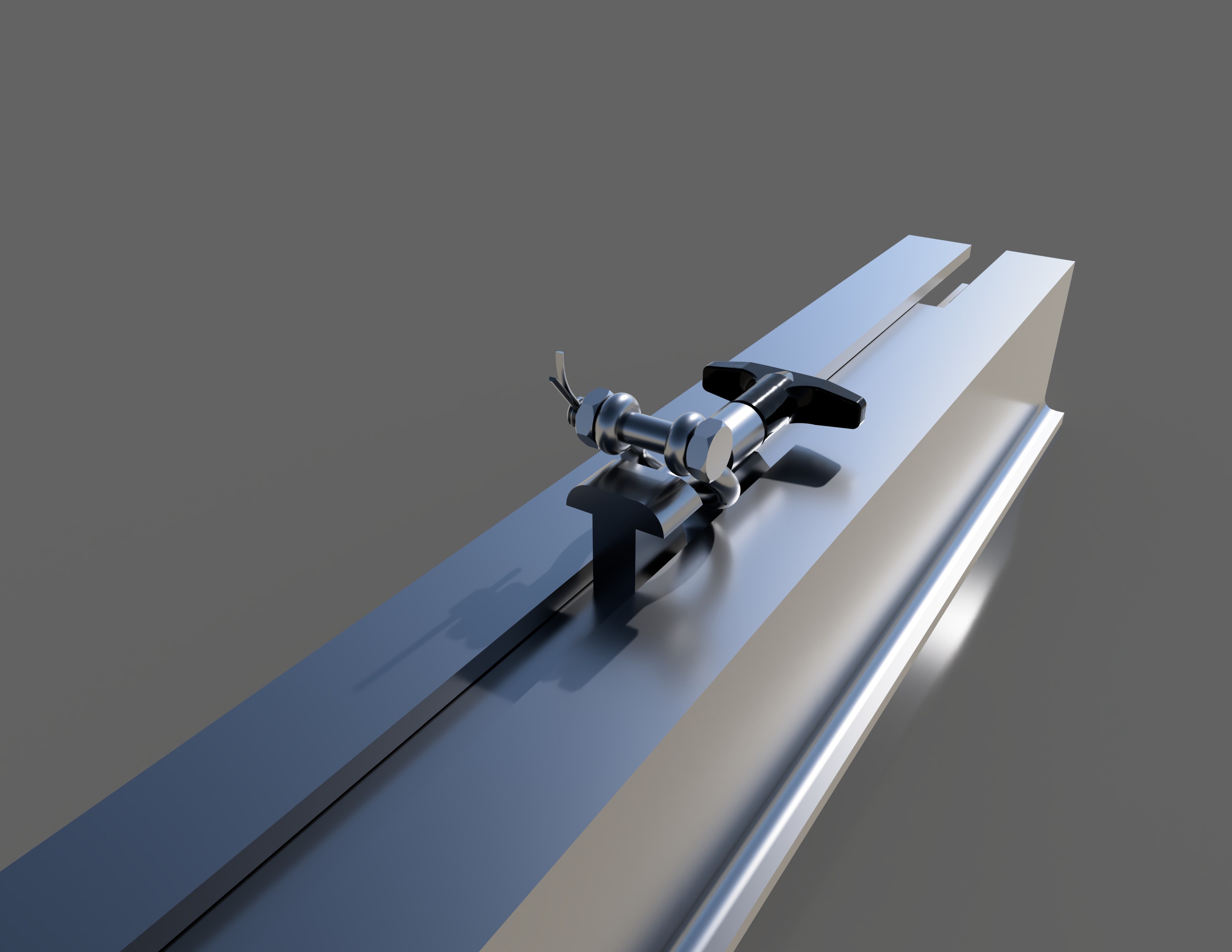

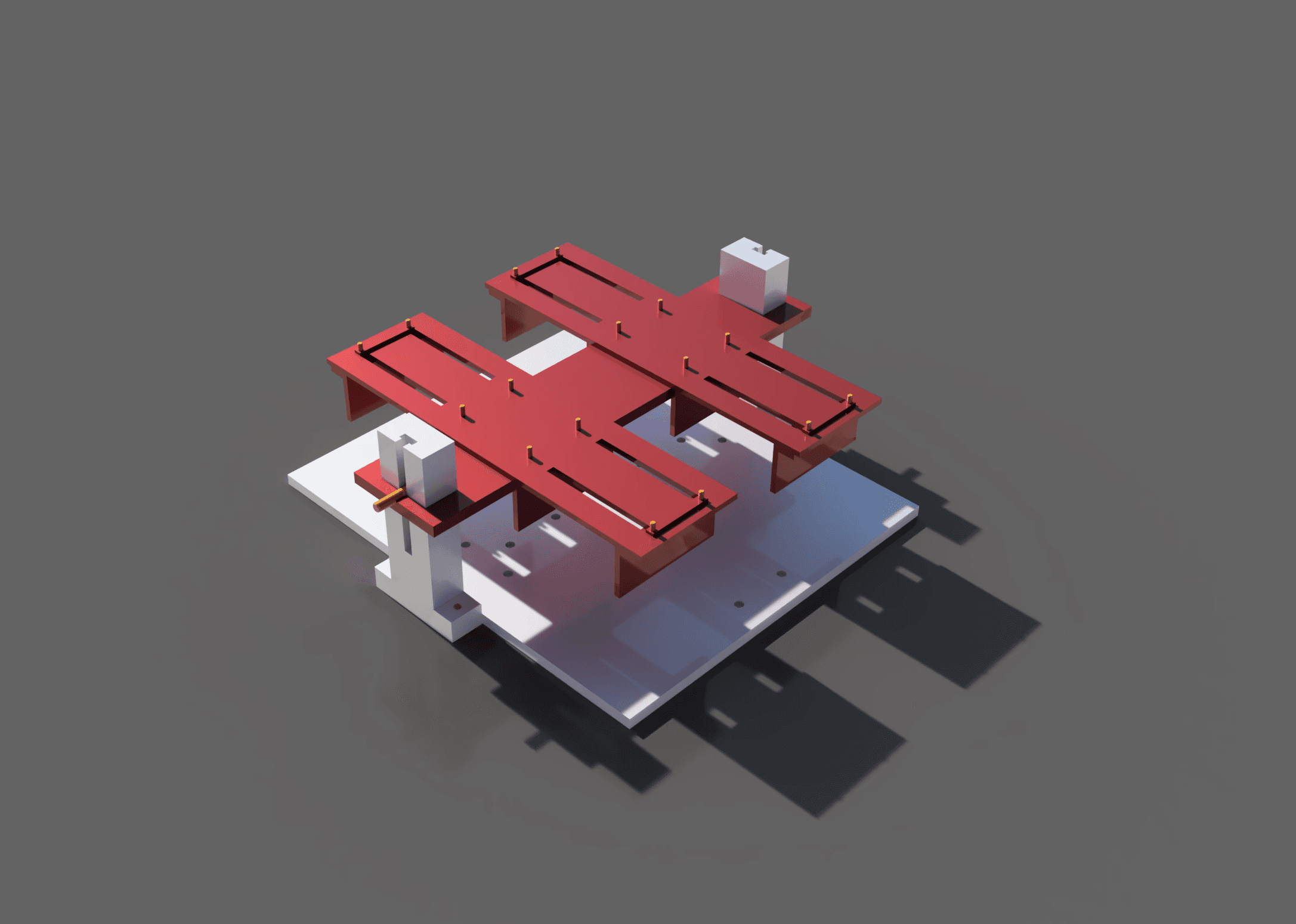

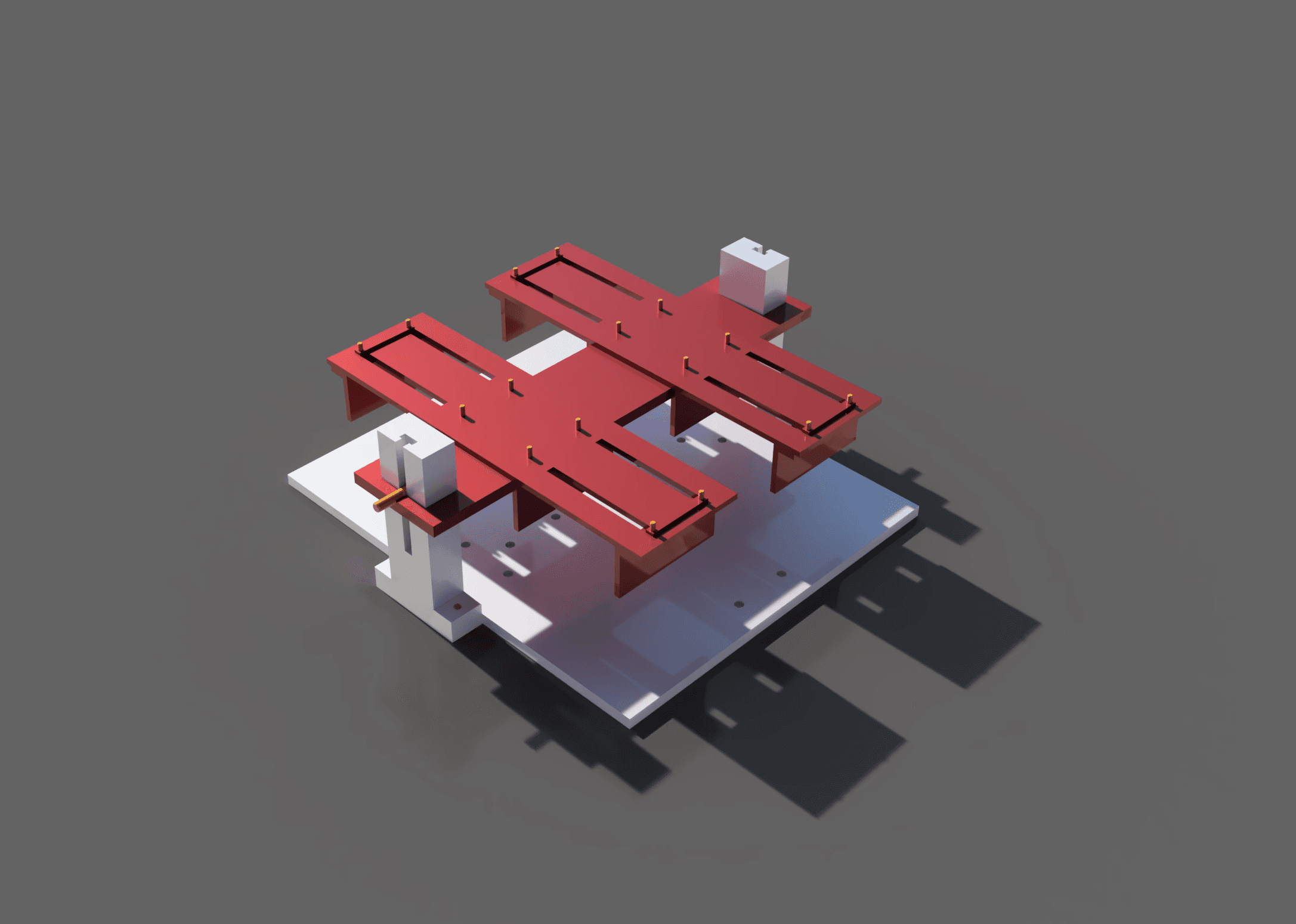

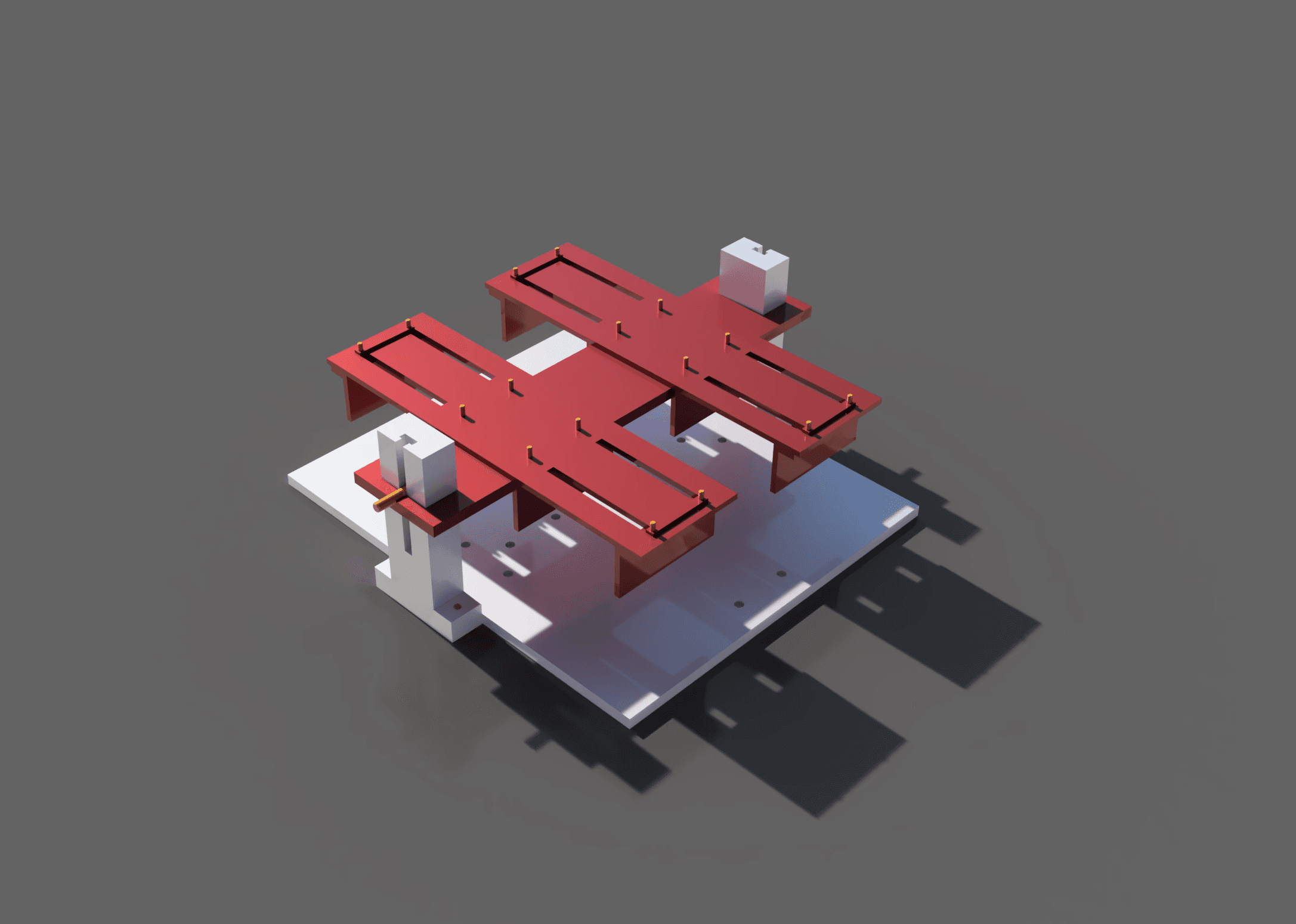

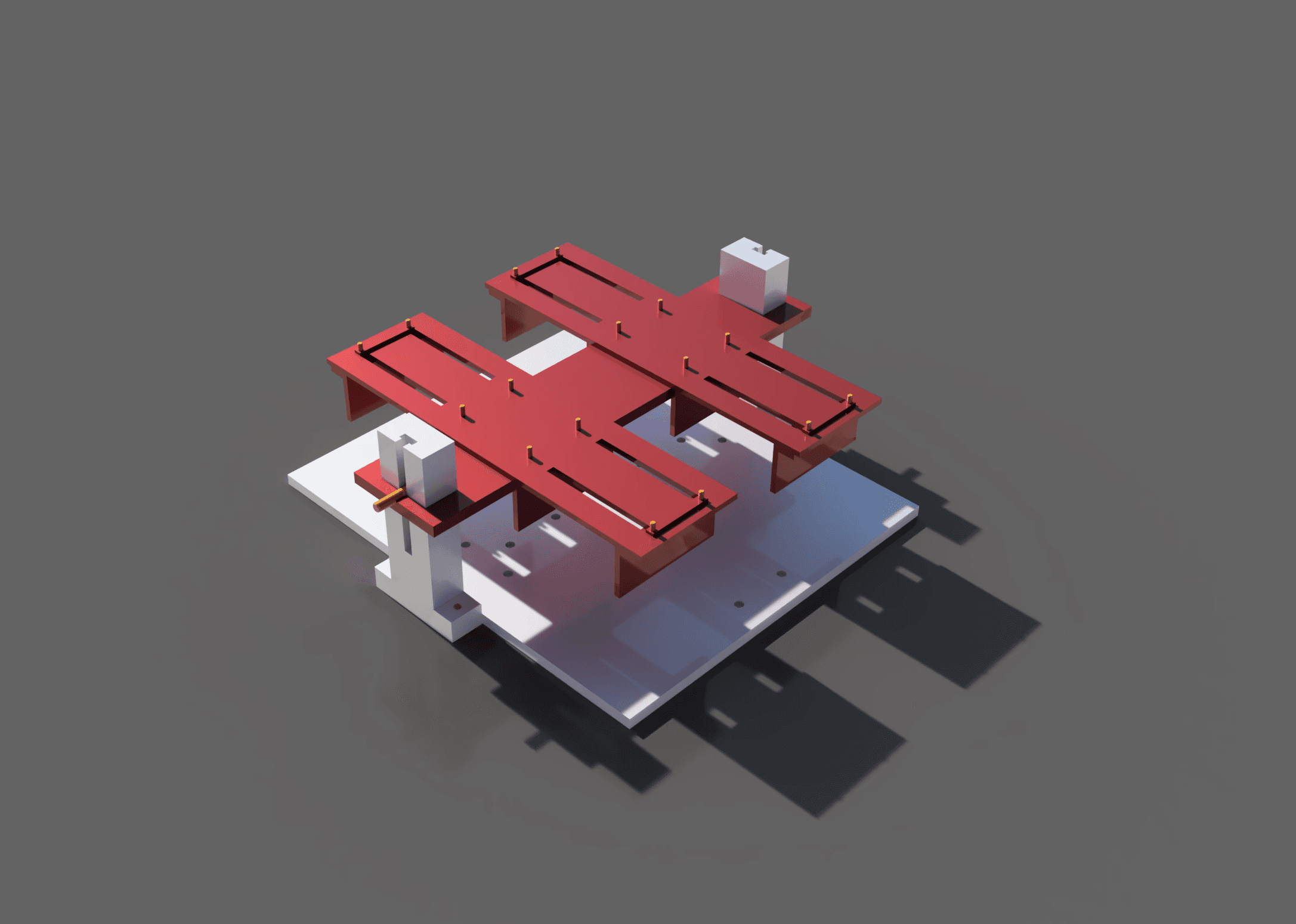

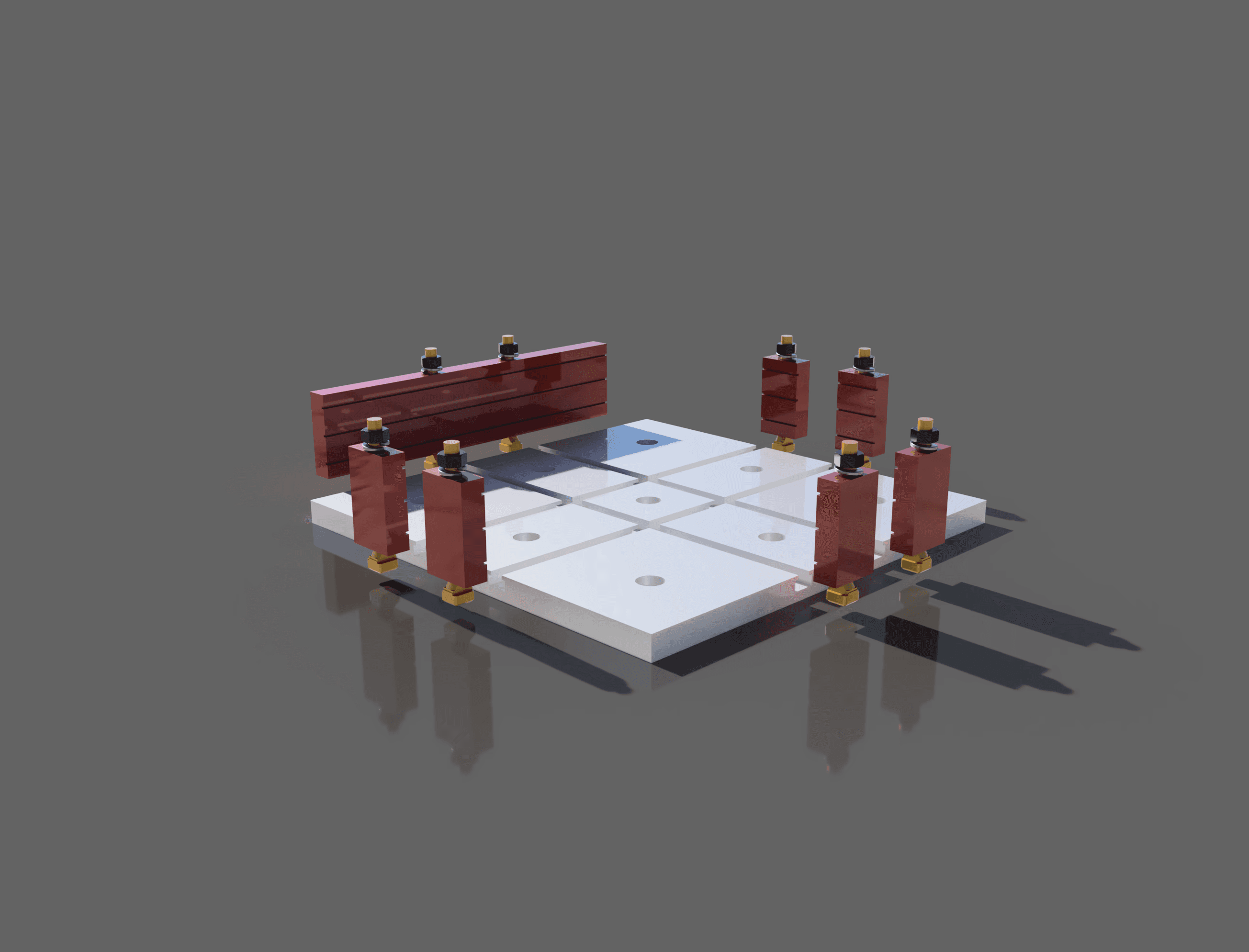

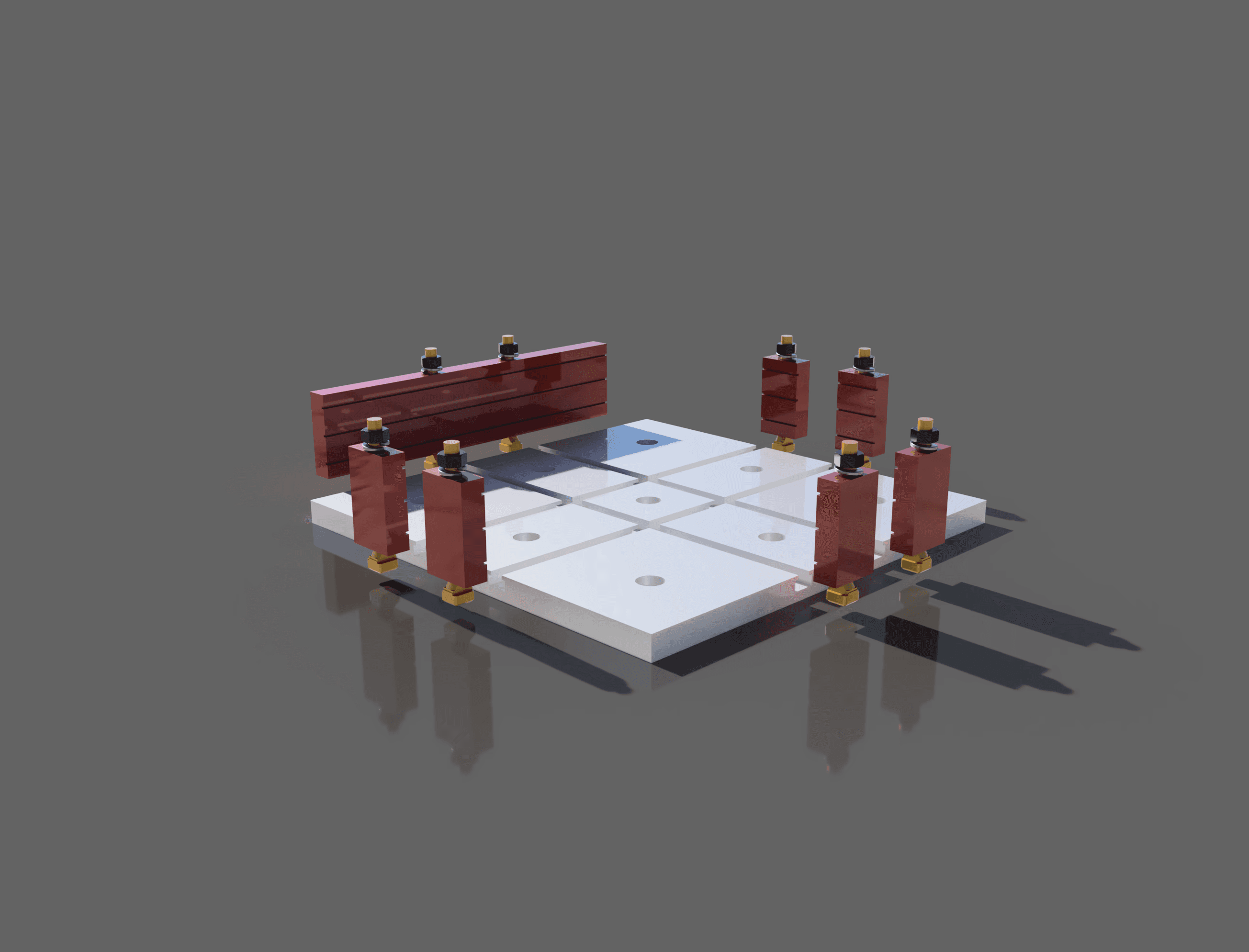

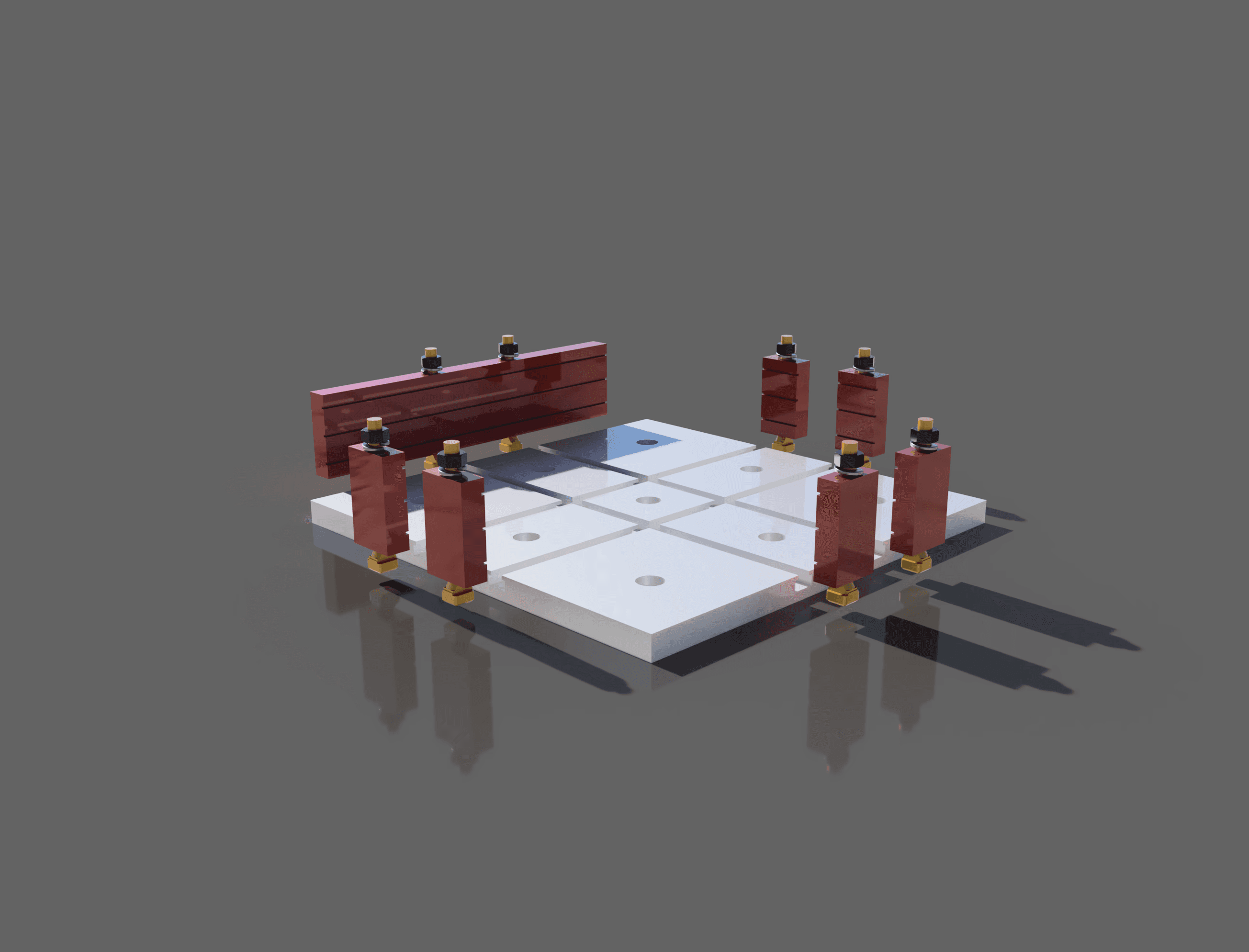

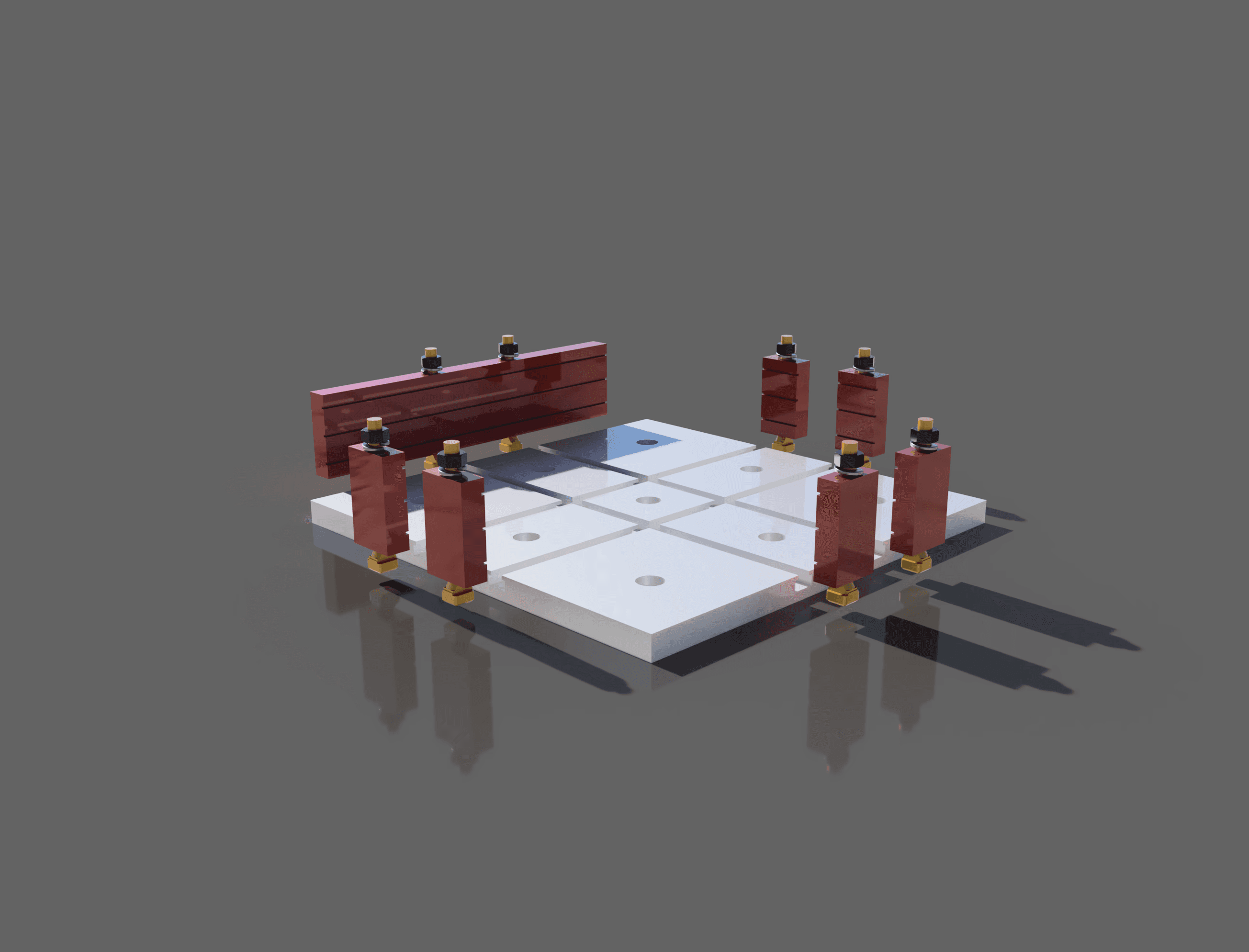

Skate and Rail Assembly

Skate and Rail Assembly

This project involved the complete design of a skate and rail assembly capable of withstanding a 32-ton load for real-life simulation applications. The engineer handled 2D drafting, 3D modeling, FEA-based stress analysis, and visual rendering to deliver a fully validated, high-strength structure.

Duration

1 Month

Year

2025

Category

Designing, Simulation

Research

Research

Initial research focused on understanding load distribution, contact behavior and material selection suitable for supporting 32 tons. Benchmarking was done using existing industrial rail systems and critical parameters like deflection limits, safety factors and wear resistance were identified to guide the design.

Initial research focused on understanding load distribution, contact behavior and material selection suitable for supporting 32 tons. Benchmarking was done using existing industrial rail systems and critical parameters like deflection limits, safety factors and wear resistance were identified to guide the design.

Research

Initial research focused on understanding load distribution, contact behavior and material selection suitable for supporting 32 tons. Benchmarking was done using existing industrial rail systems and critical parameters like deflection limits, safety factors and wear resistance were identified to guide the design.

Design

Design

The assembly was designed from the ground up using 3D CAD, with attention to load paths, structural reinforcements and ease of fabrication. Detailed 2D drawings were created for manufacturing and special care was taken to ensure proper alignment and contact between the skate and rail under high loads.

The assembly was designed from the ground up using 3D CAD, with attention to load paths, structural reinforcements and ease of fabrication. Detailed 2D drawings were created for manufacturing and special care was taken to ensure proper alignment and contact between the skate and rail under high loads.

Design

The assembly was designed from the ground up using 3D CAD, with attention to load paths, structural reinforcements and ease of fabrication. Detailed 2D drawings were created for manufacturing and special care was taken to ensure proper alignment and contact between the skate and rail under high loads.

Development

Development

The design was validated through CAE simulations, including stress, strain and deflection analysis under full load conditions. Iterative refinements were made to strengthen critical areas and ensure safety margins. Final outputs included high-quality renders and detailed drawings for fabrication.

The design was validated through CAE simulations, including stress, strain and deflection analysis under full load conditions. Iterative refinements were made to strengthen critical areas and ensure safety margins. Final outputs included high-quality renders and detailed drawings for fabrication.

Development

The design was validated through CAE simulations, including stress, strain and deflection analysis under full load conditions. Iterative refinements were made to strengthen critical areas and ensure safety margins. Final outputs included high-quality renders and detailed drawings for fabrication.

Concept

Concept

The goal was to create a durable and reliable system capable of handling extreme loads without compromising precision. The design emphasized structural integrity, repeatability, and ease of assembly—making it suitable for rigorous real-world simulation scenarios.

The goal was to create a durable and reliable system capable of handling extreme loads without compromising precision. The design emphasized structural integrity, repeatability, and ease of assembly—making it suitable for rigorous real-world simulation scenarios.

Concept

The goal was to create a durable and reliable system capable of handling extreme loads without compromising precision. The design emphasized structural integrity, repeatability, and ease of assembly—making it suitable for rigorous real-world simulation scenarios.

More Works More Works

More Works More Works

LRU Vibration Fixture

Designing & Simulation

2024

2024

LRU Vibration Fixture

Designing & Simulation

2024

2024

LRU Vibration Fixture

Designing & Simulation

2024

2024

LRU Vibration Fixture

Designing & Simulation

2024

2024

PCB Vibration Fixture

Designing & Simulation

2024

2024

PCB Vibration Fixture

Designing & Simulation

2024

2024

PCB Vibration Fixture

Designing & Simulation

2024

2024

PCB Vibration Fixture

Designing & Simulation

2024

2024

©2024 MANDRO DESIGN

GO BACK TO TOP

©2024 MANDRO DESIGN

GO BACK TO TOP