LOCAL/

10:47:45 AM

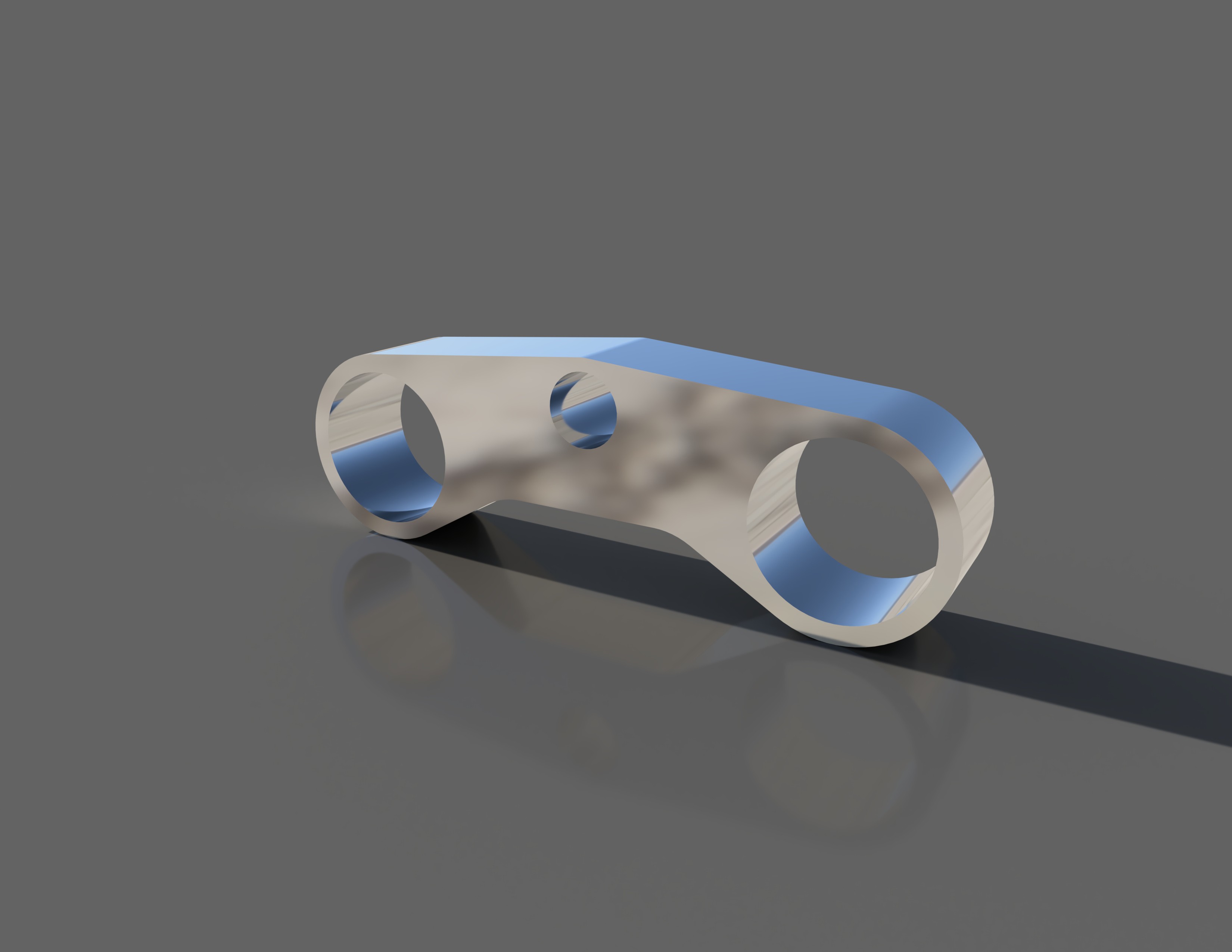

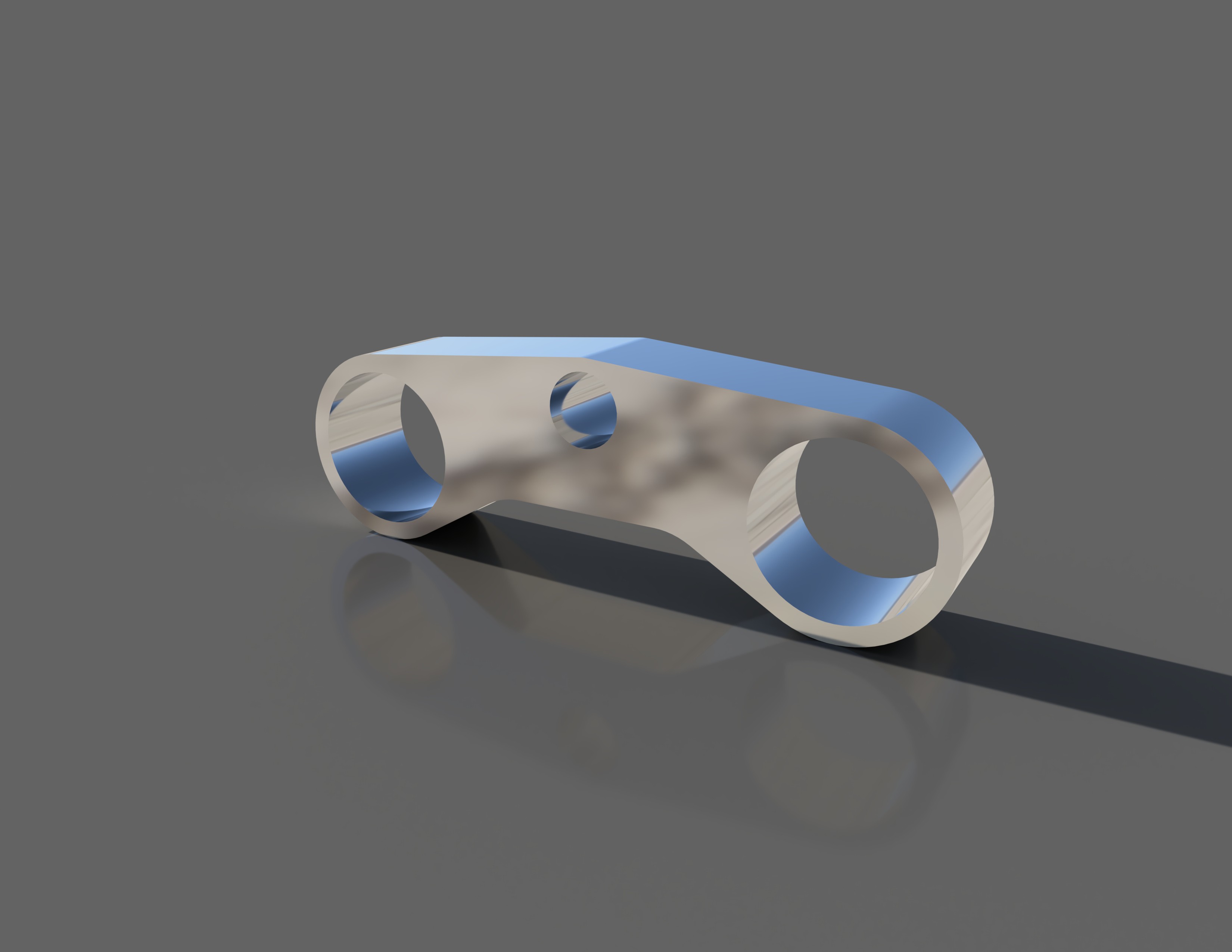

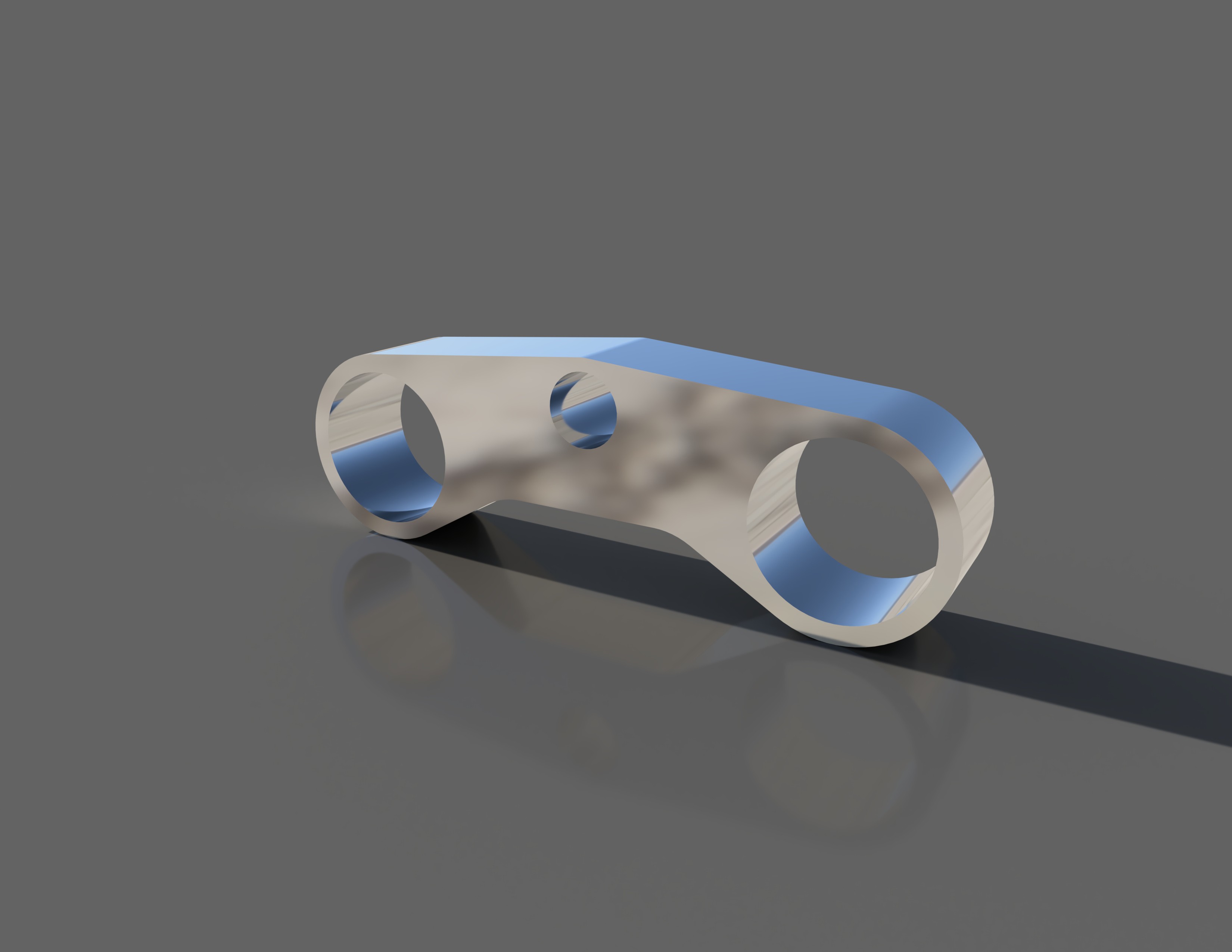

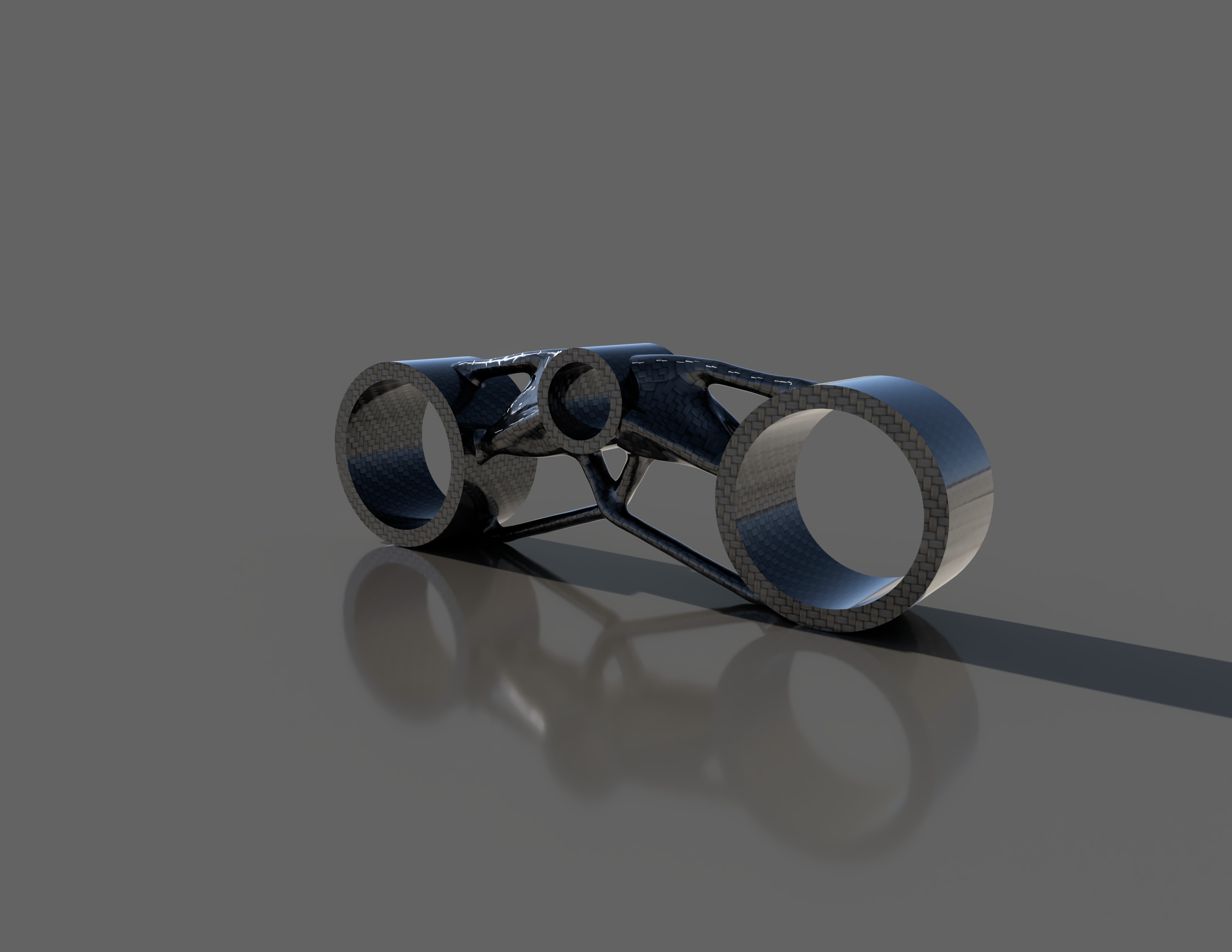

Motorcycle Triple Clamp

Motorcycle Triple Clamp

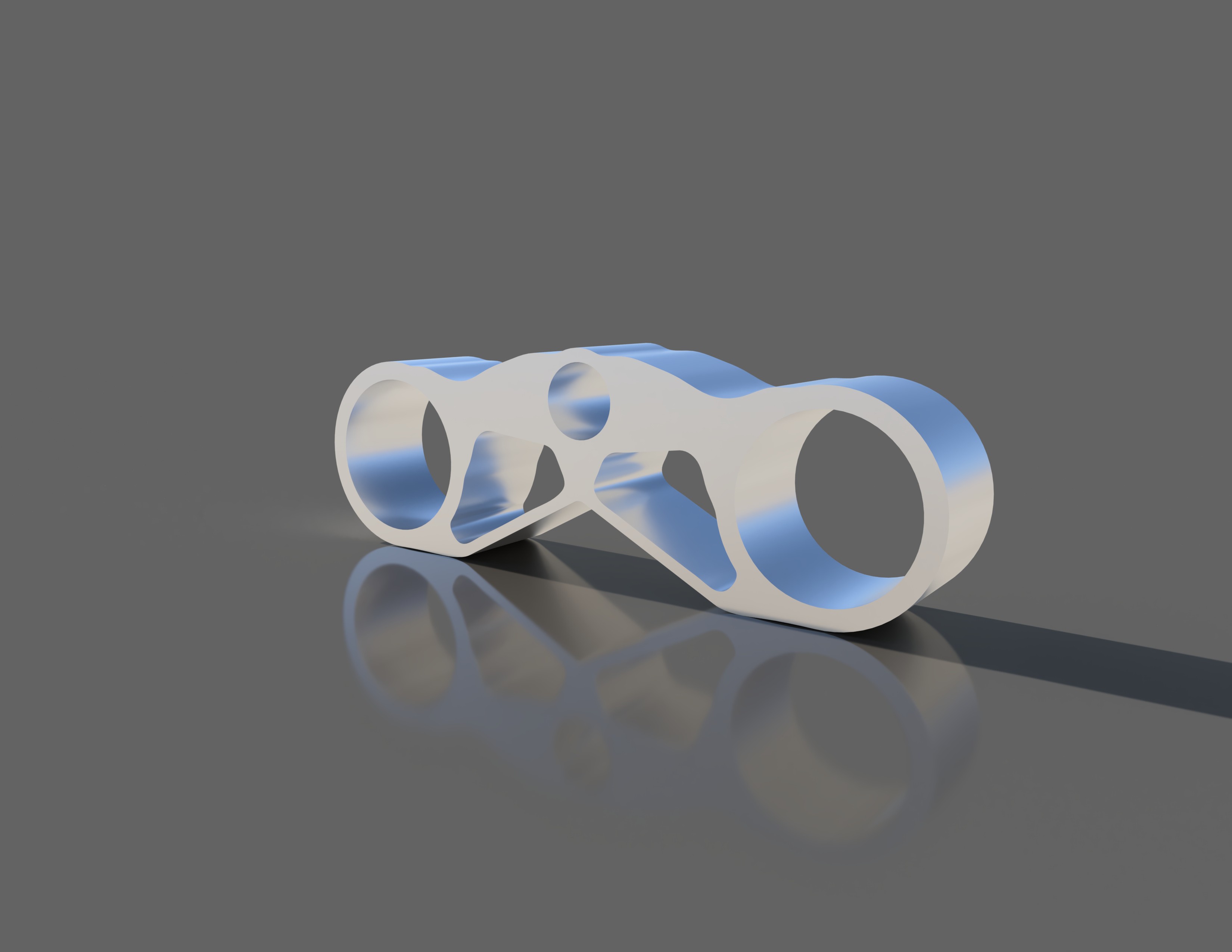

Redesigned a motorcycle triple clamp using generative design to reduce weight while maintaining structural integrity. The final geometry was optimized for real-world loads and manufacturability.

Duration

1 Month

Year

2024

Category

Generative Design

Research

Research

The project began by studying the loading conditions, mounting interfaces and dimensional constraints of the stock triple clamp. Material properties and real-world stress points were analyzed to define boundary conditions and performance targets for the generative design process.

The project began by studying the loading conditions, mounting interfaces and dimensional constraints of the stock triple clamp. Material properties and real-world stress points were analyzed to define boundary conditions and performance targets for the generative design process.

Research

The project began by studying the loading conditions, mounting interfaces and dimensional constraints of the stock triple clamp. Material properties and real-world stress points were analyzed to define boundary conditions and performance targets for the generative design process.

Design

Design

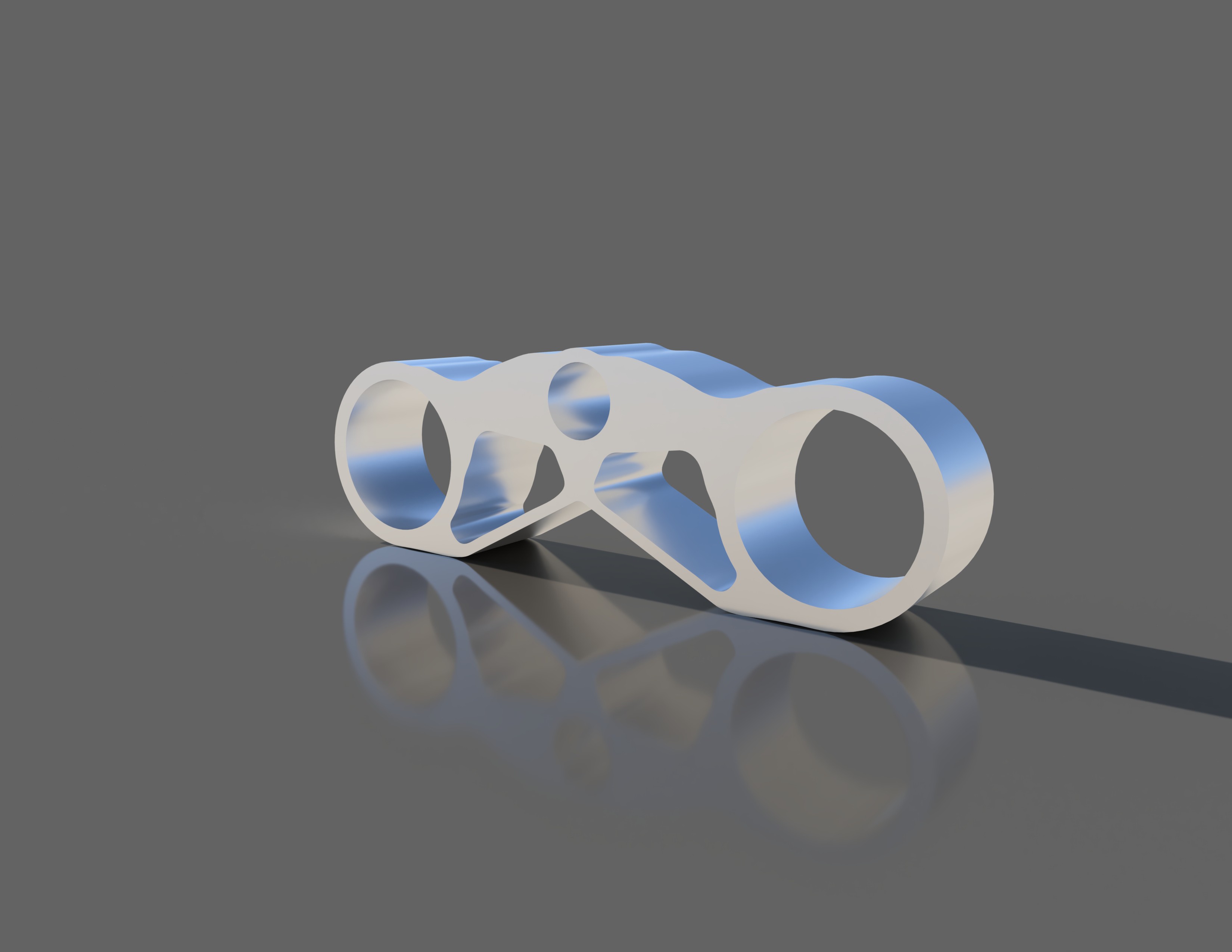

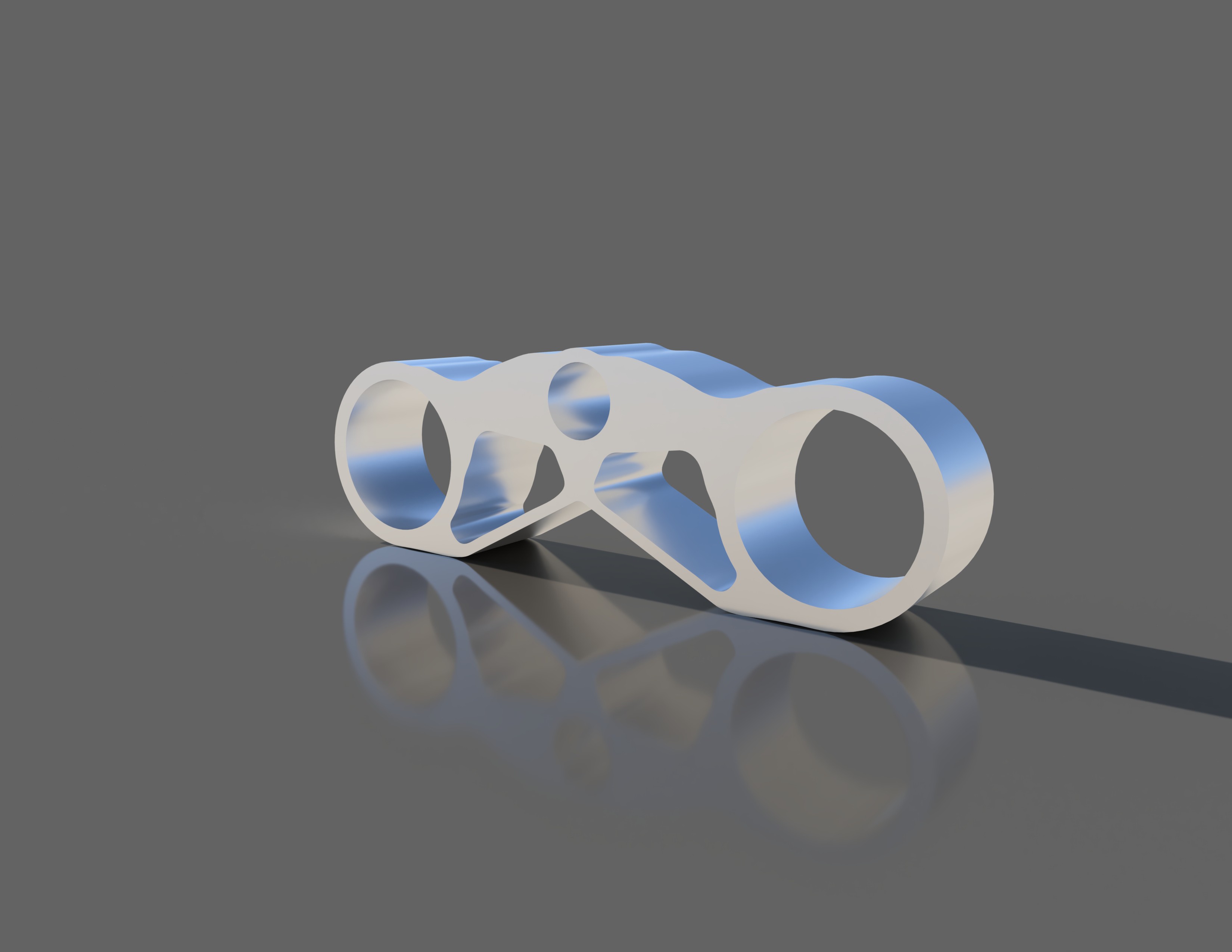

The design process included three key iterations: starting with a CAD model of the stock part, followed by a manually optimized version with reduced material and finally a generative design model based on defined constraints and load cases. Each step focused on improving strength-to-weight efficiency while preserving critical mounting geometry.

The design process included three key iterations: starting with a CAD model of the stock part, followed by a manually optimized version with reduced material and finally a generative design model based on defined constraints and load cases. Each step focused on improving strength-to-weight efficiency while preserving critical mounting geometry.

Design

The design process included three key iterations: starting with a CAD model of the stock part, followed by a manually optimized version with reduced material and finally a generative design model based on defined constraints and load cases. Each step focused on improving strength-to-weight efficiency while preserving critical mounting geometry.

Development

Development

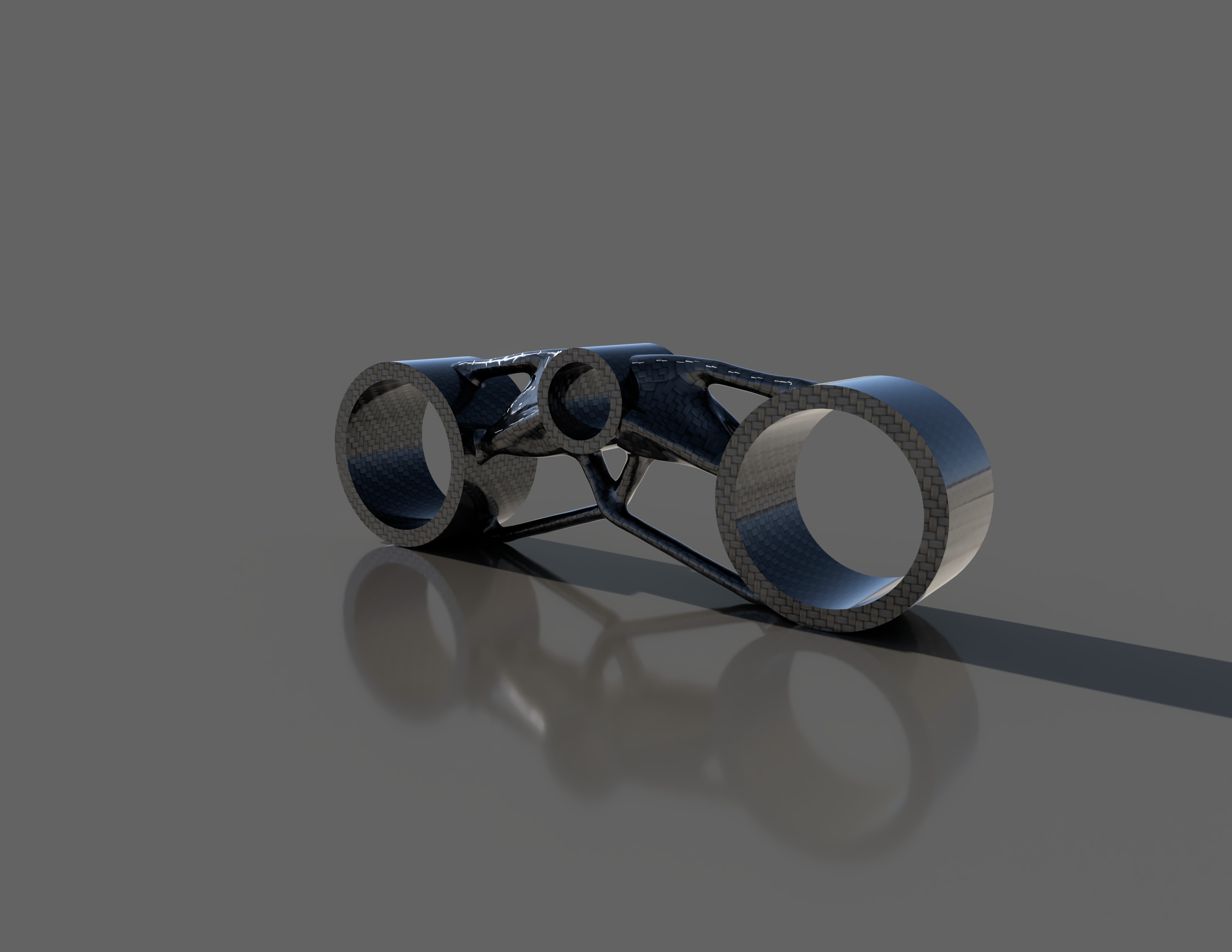

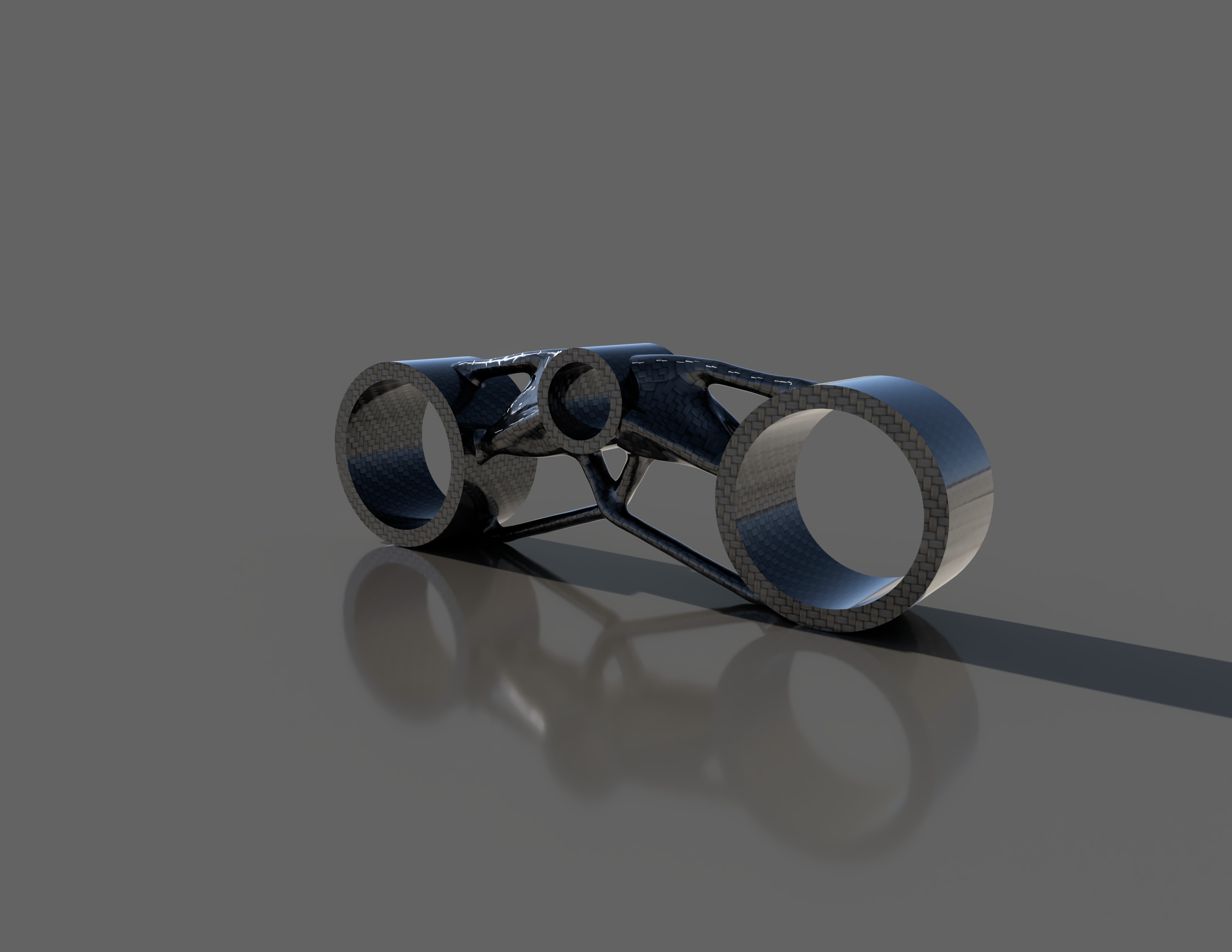

The final generative design was optimized for additive manufacturing due to its complex geometry, which could not be machined conventionally. Post-processing involved reinforcing the part with carbon fiber to enhance strength and stiffness, making it suitable for real-world performance conditions.

The final generative design was optimized for additive manufacturing due to its complex geometry, which could not be machined conventionally. Post-processing involved reinforcing the part with carbon fiber to enhance strength and stiffness, making it suitable for real-world performance conditions.

Development

The final generative design was optimized for additive manufacturing due to its complex geometry, which could not be machined conventionally. Post-processing involved reinforcing the part with carbon fiber to enhance strength and stiffness, making it suitable for real-world performance conditions.

Concept

Concept

The goal was to push beyond traditional design limits by using generative algorithms to create a lightweight yet structurally sound triple clamp. By embracing additive manufacturing and carbon fiber reinforcement, the concept aimed to explore high-performance, future-ready solutions for motorcycle components.

The goal was to push beyond traditional design limits by using generative algorithms to create a lightweight yet structurally sound triple clamp. By embracing additive manufacturing and carbon fiber reinforcement, the concept aimed to explore high-performance, future-ready solutions for motorcycle components.

Concept

The goal was to push beyond traditional design limits by using generative algorithms to create a lightweight yet structurally sound triple clamp. By embracing additive manufacturing and carbon fiber reinforcement, the concept aimed to explore high-performance, future-ready solutions for motorcycle components.

More Works More Works

More Works More Works

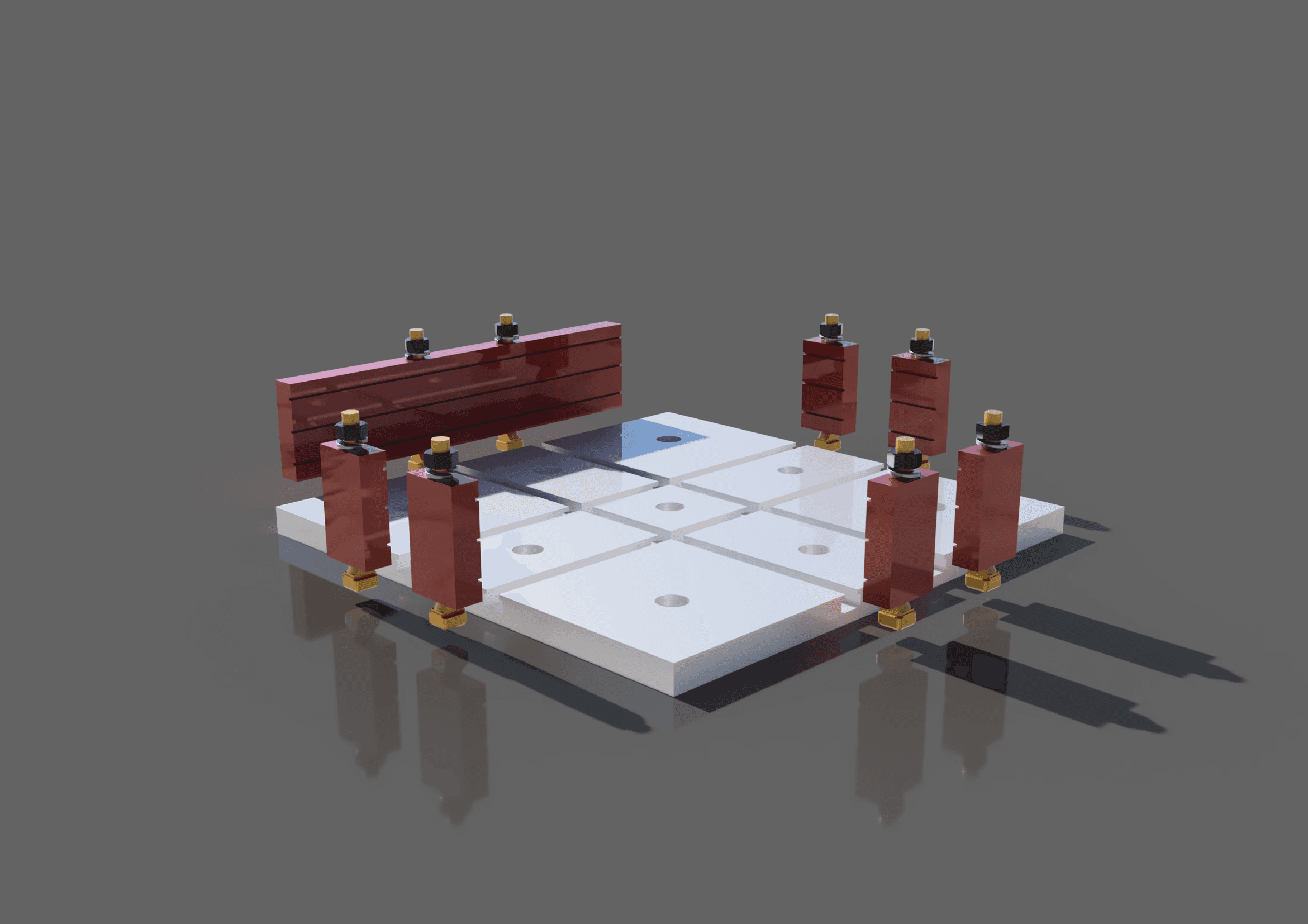

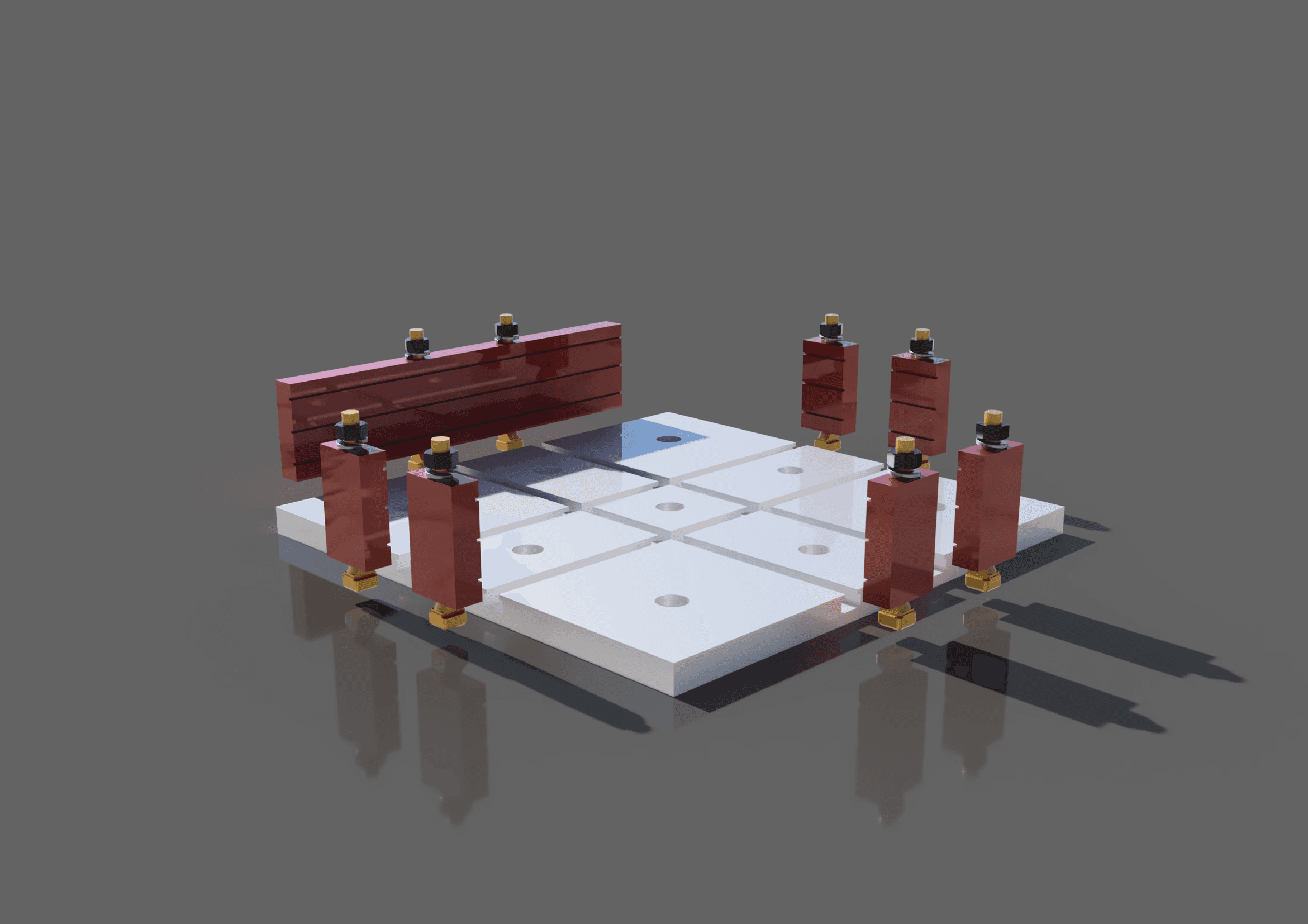

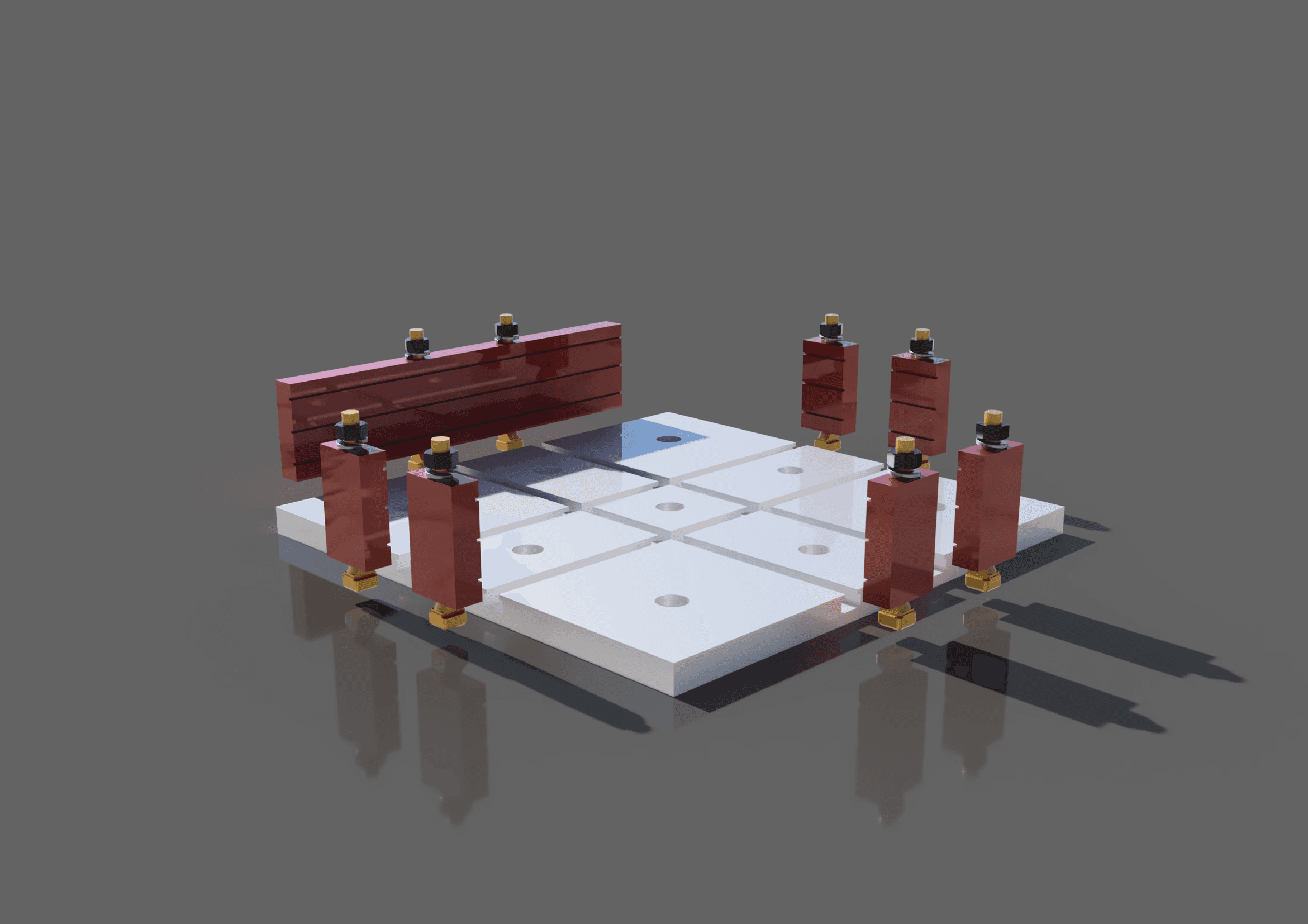

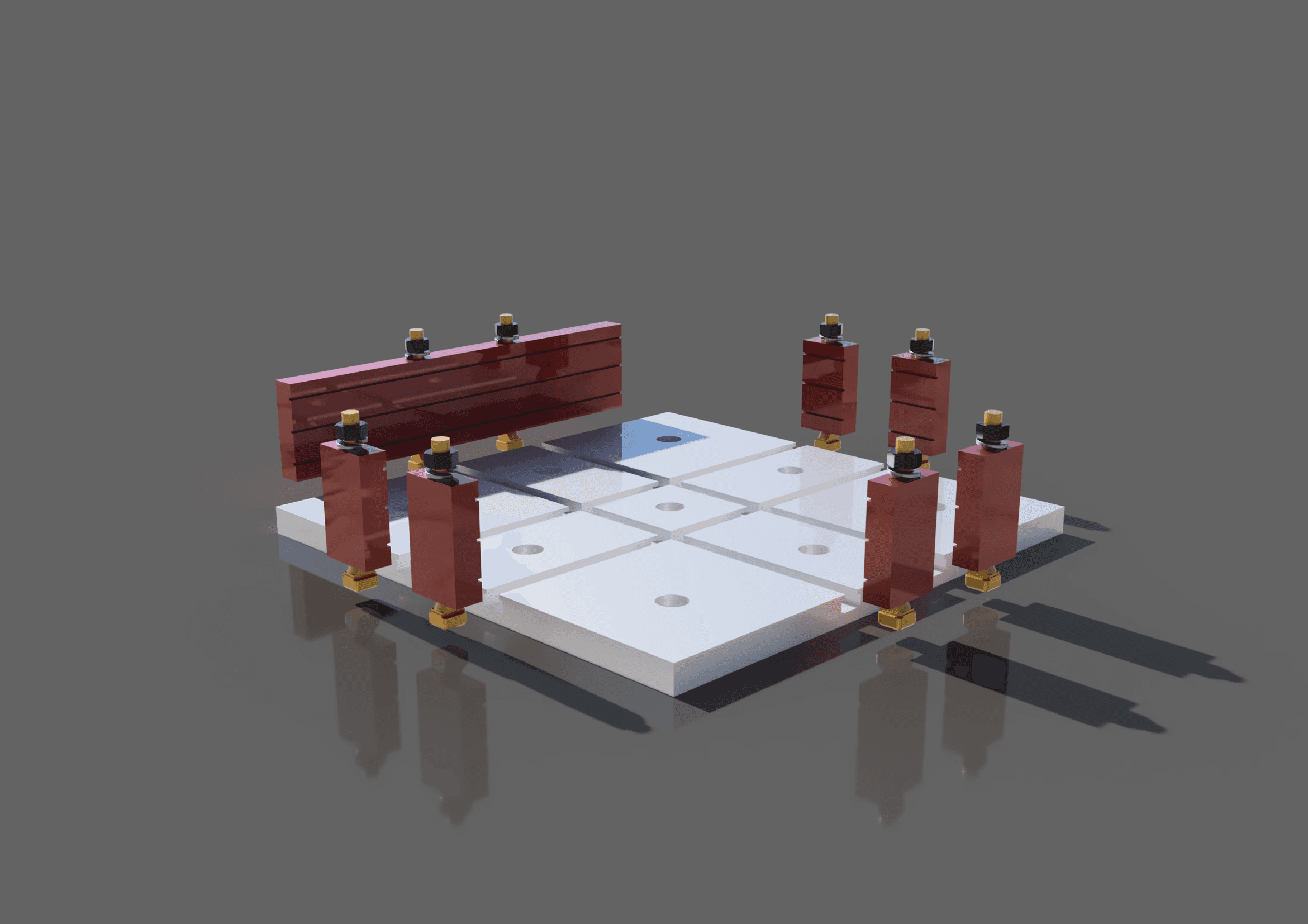

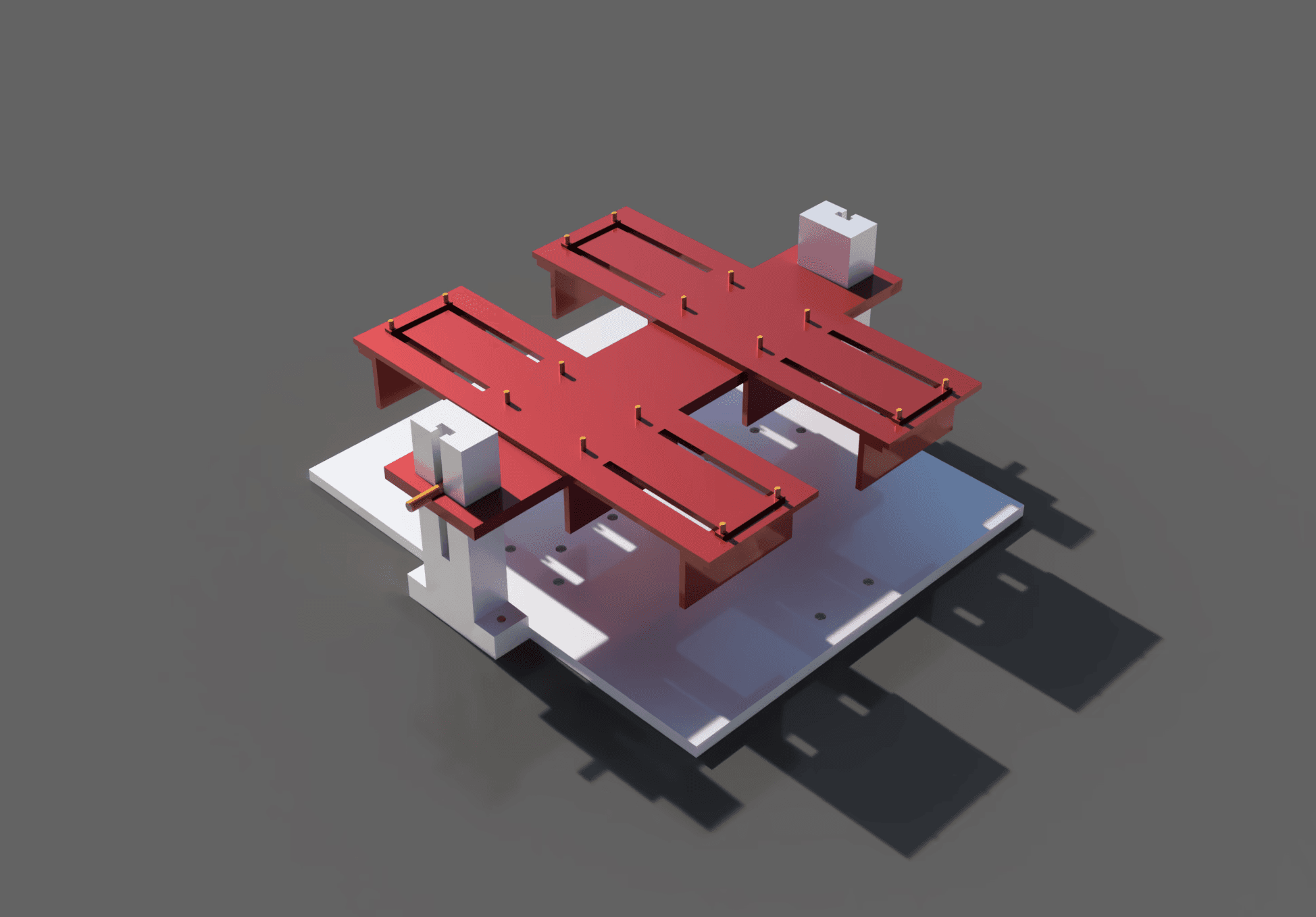

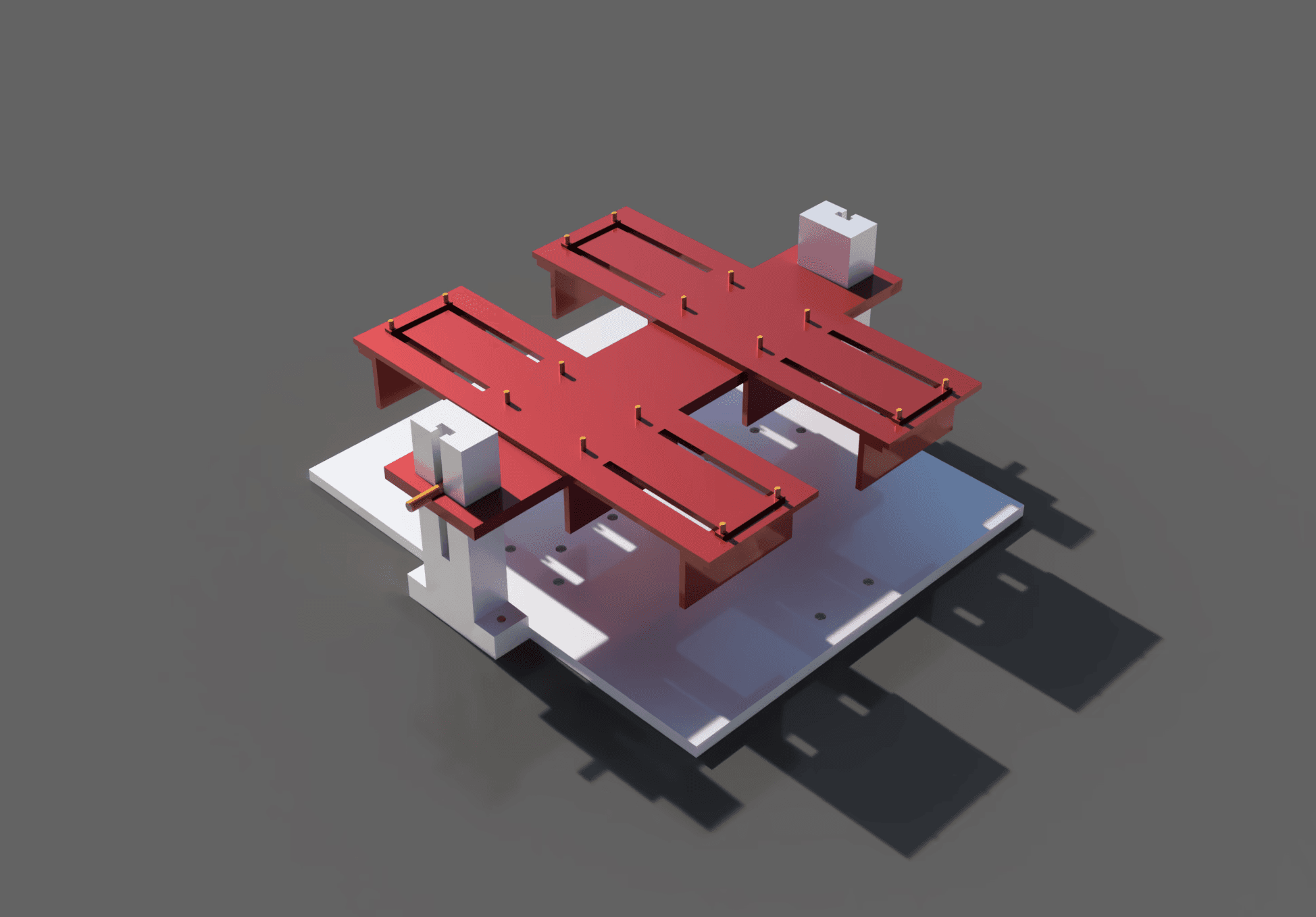

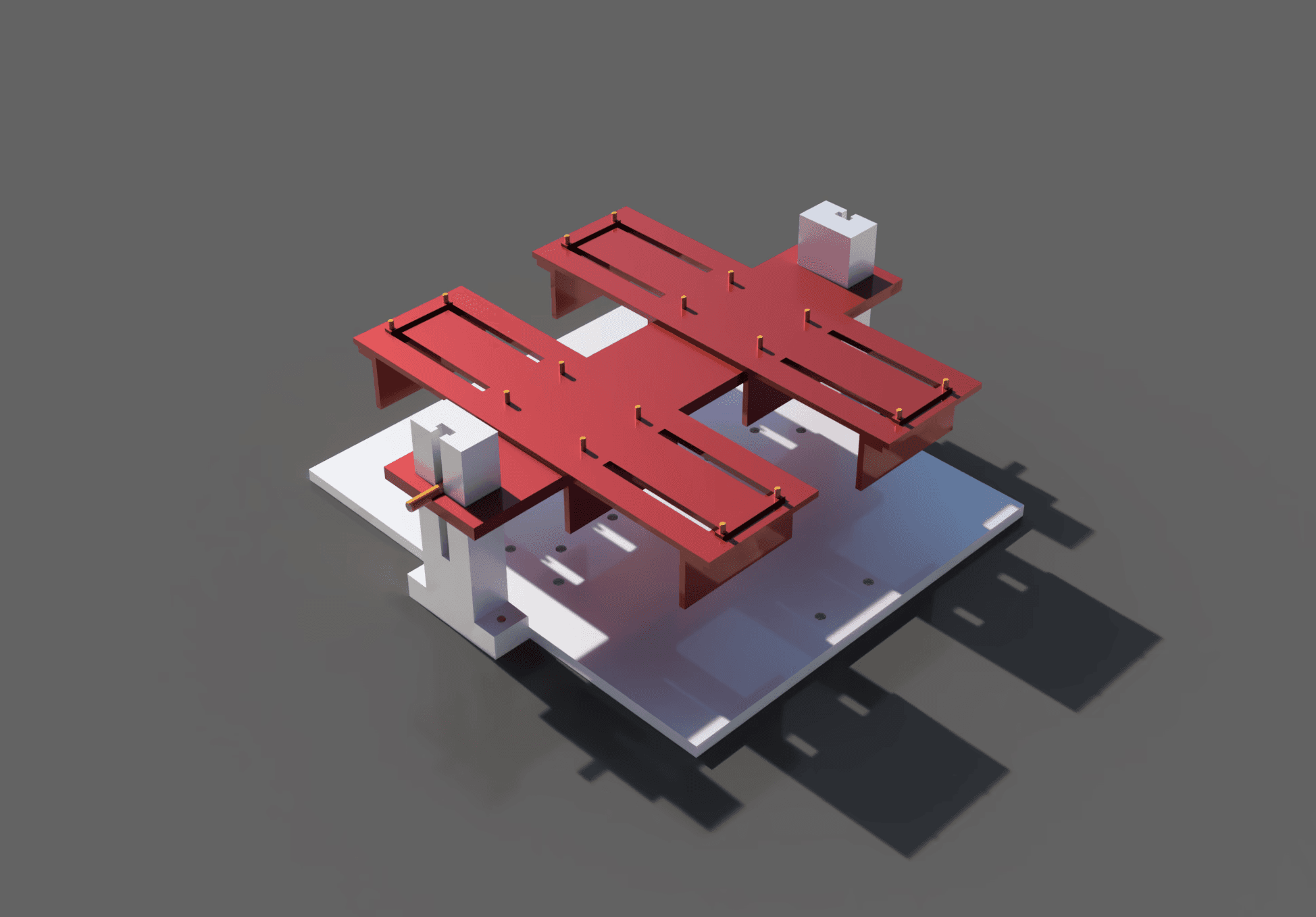

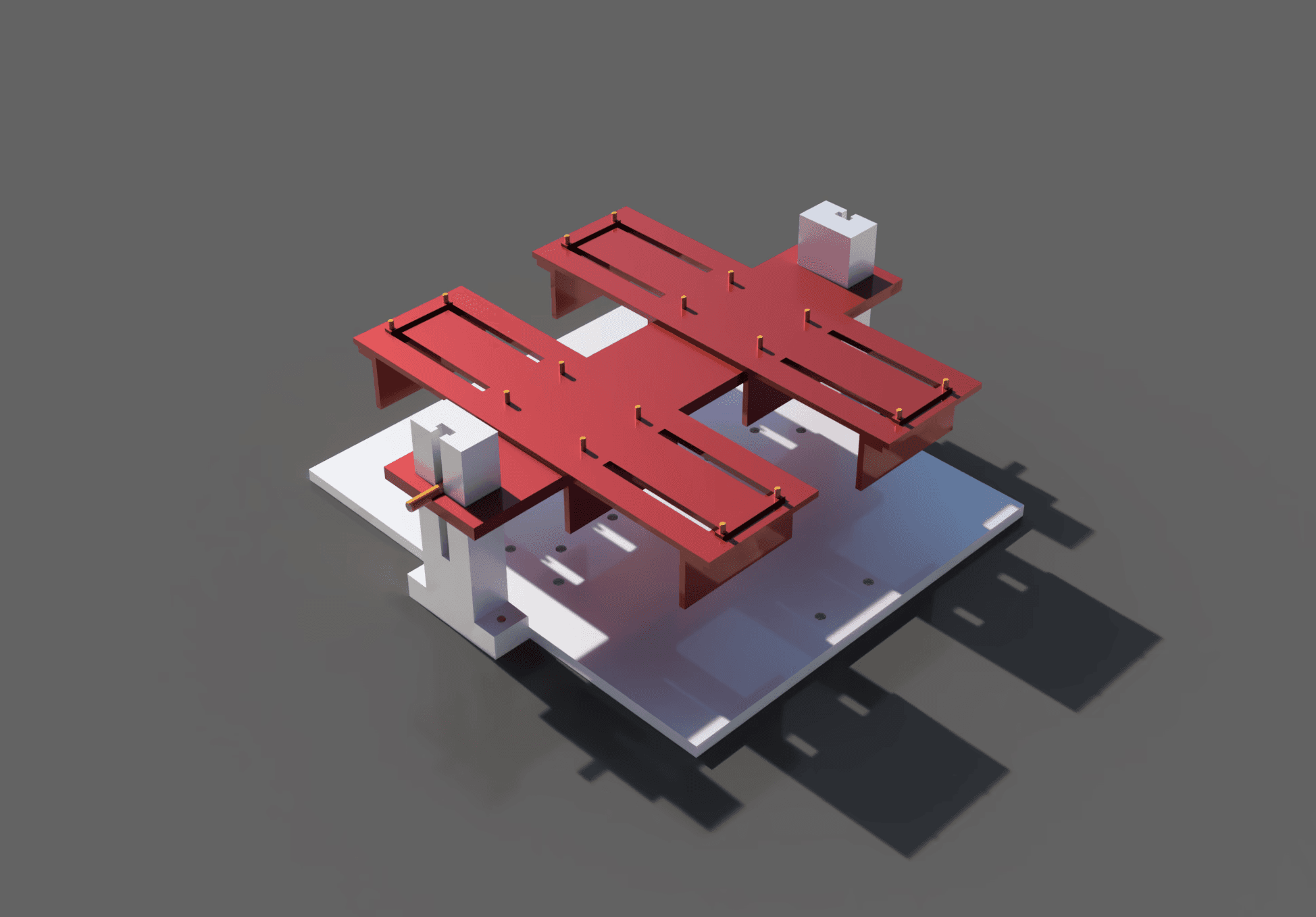

PCB Vibration Fixture

Desinging & SImulation

2024

2024

PCB Vibration Fixture

Desinging & SImulation

2024

2024

PCB Vibration Fixture

Desinging & SImulation

2024

2024

PCB Vibration Fixture

Desinging & SImulation

2024

2024

LRU Vibtraion Fixture

Designing & Simulation

2024

2024

LRU Vibtraion Fixture

Designing & Simulation

2024

2024

LRU Vibtraion Fixture

Designing & Simulation

2024

2024

LRU Vibtraion Fixture

Designing & Simulation

2024

2024

©2024 MANDRO DESIGN

GO BACK TO TOP

©2024 MANDRO DESIGN

GO BACK TO TOP