LOCAL/

10:47:45 AM

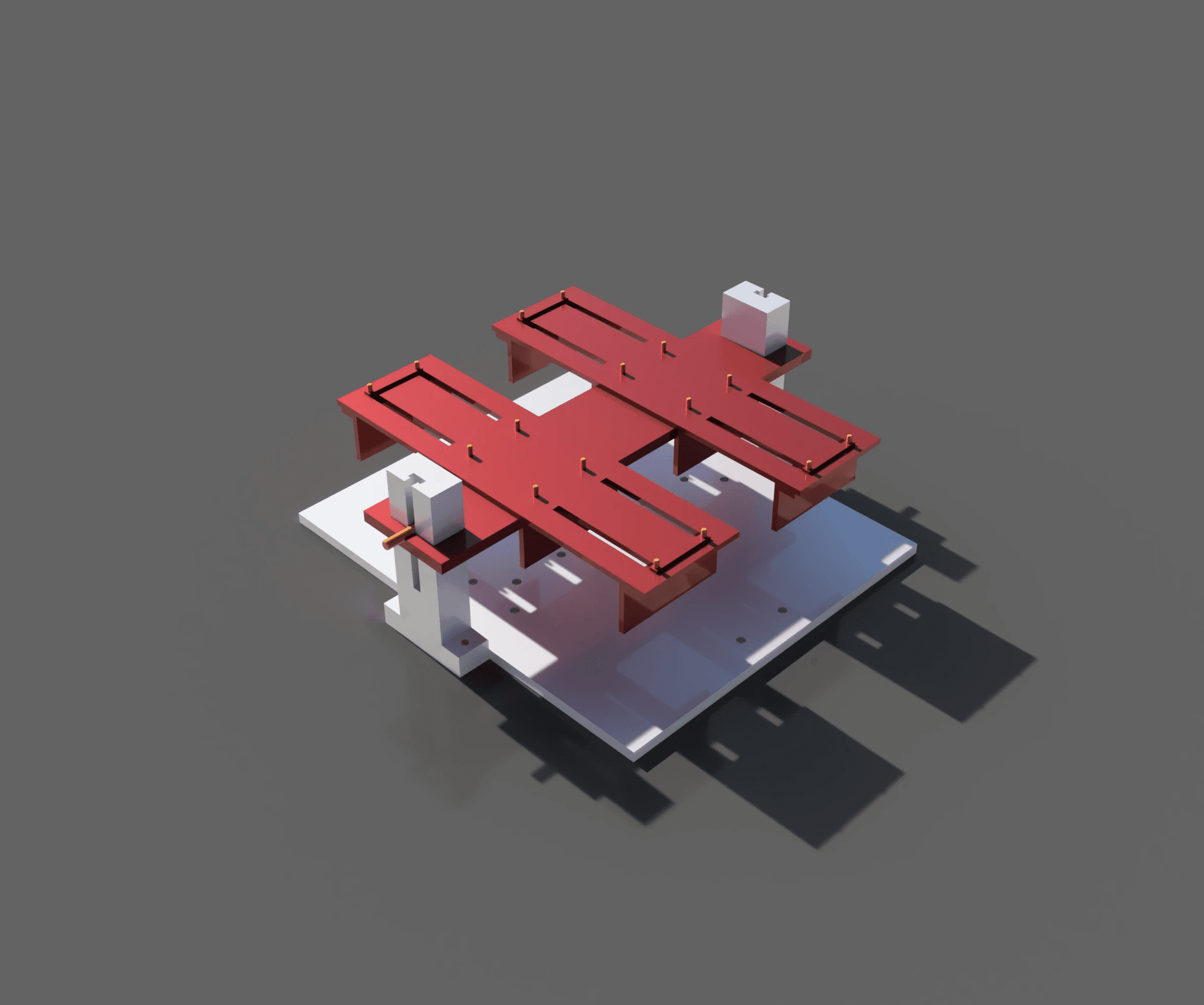

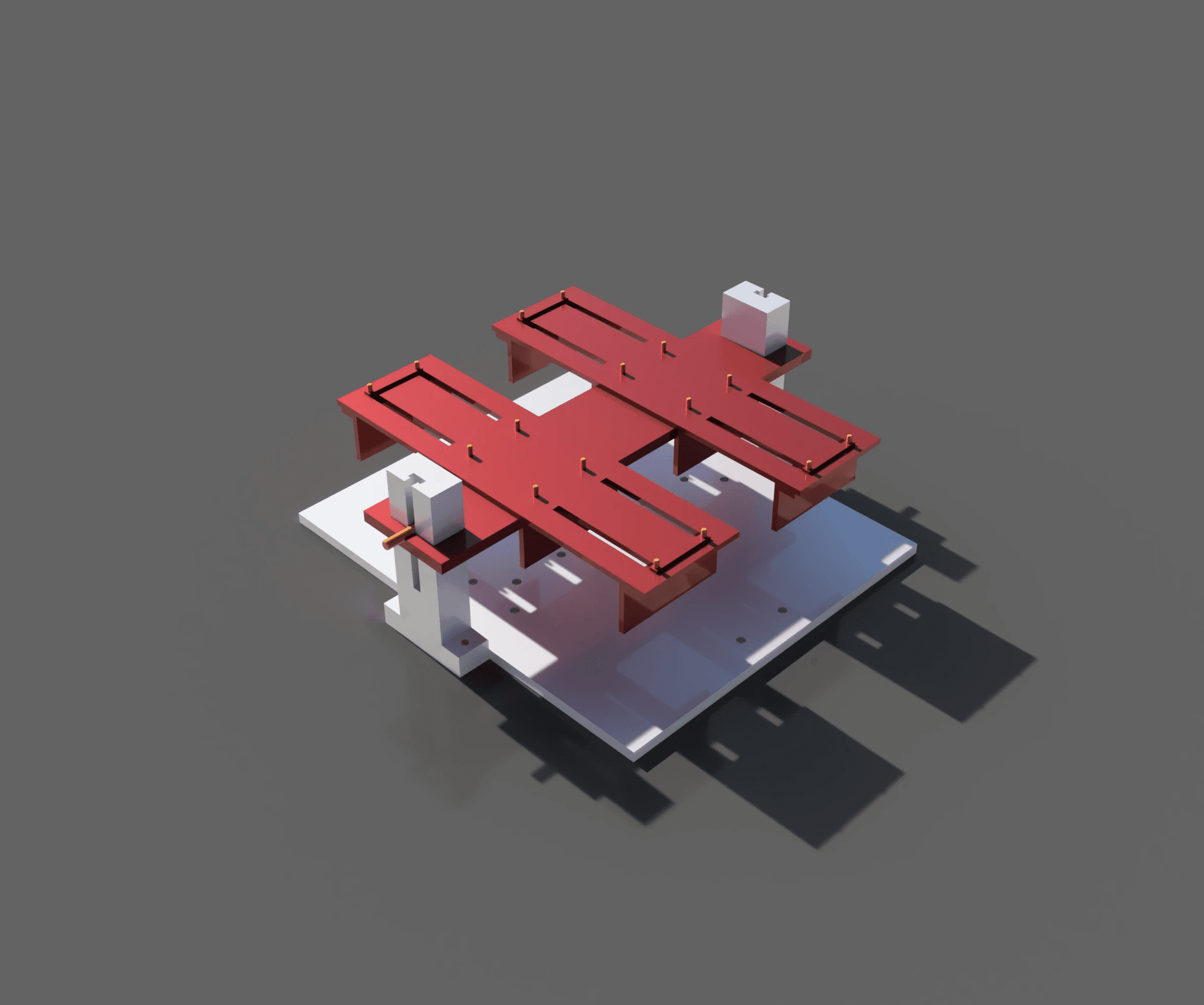

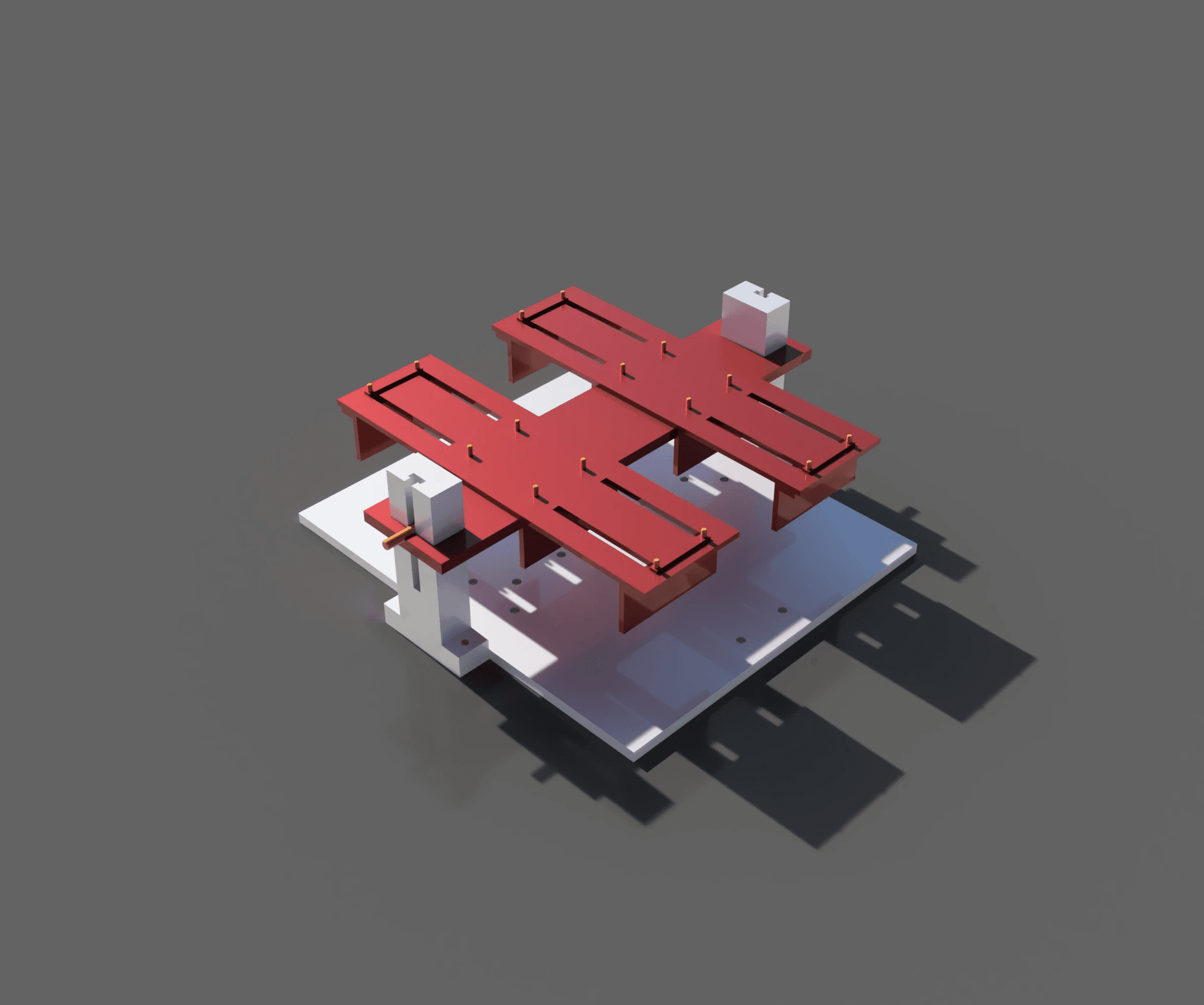

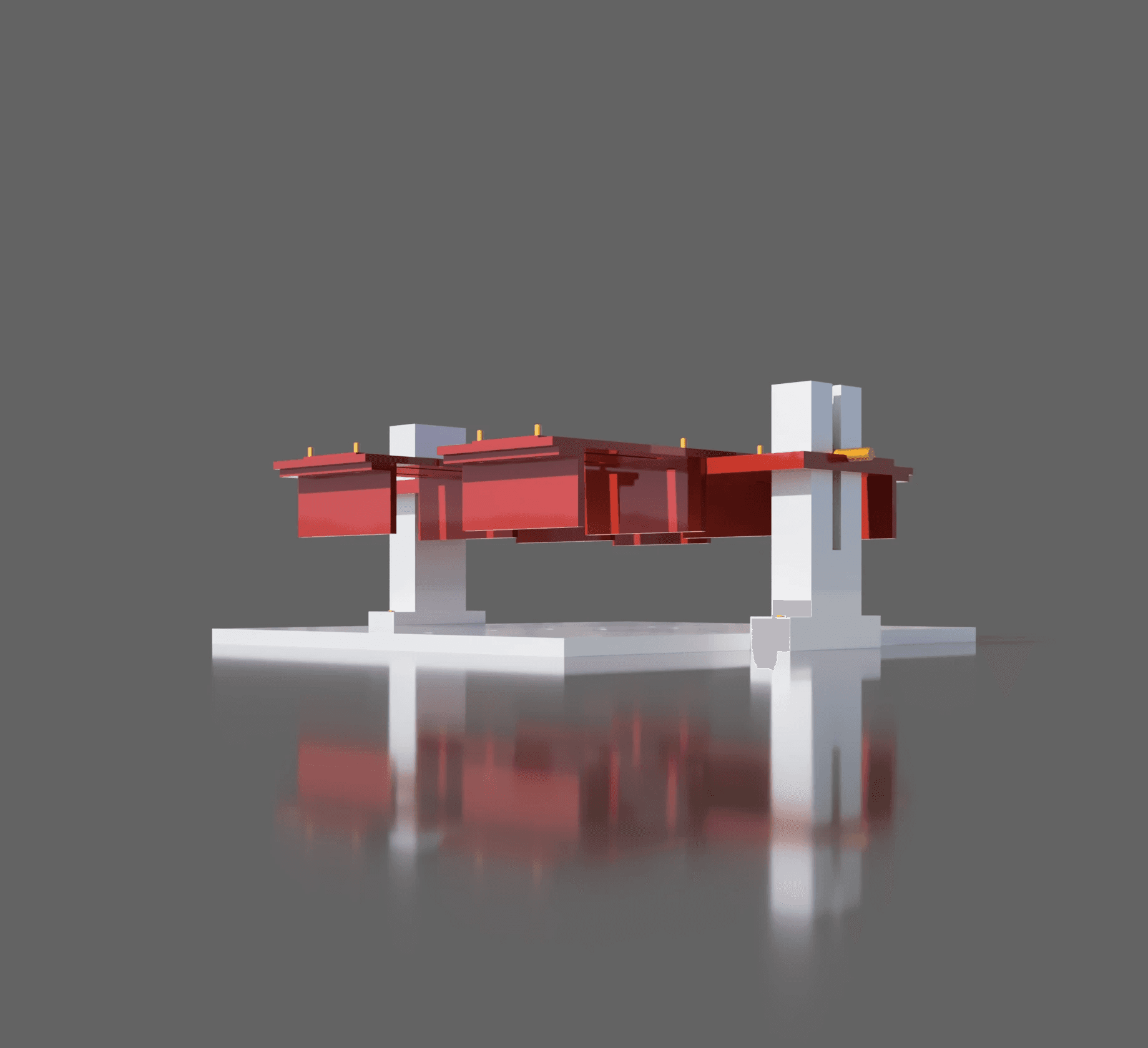

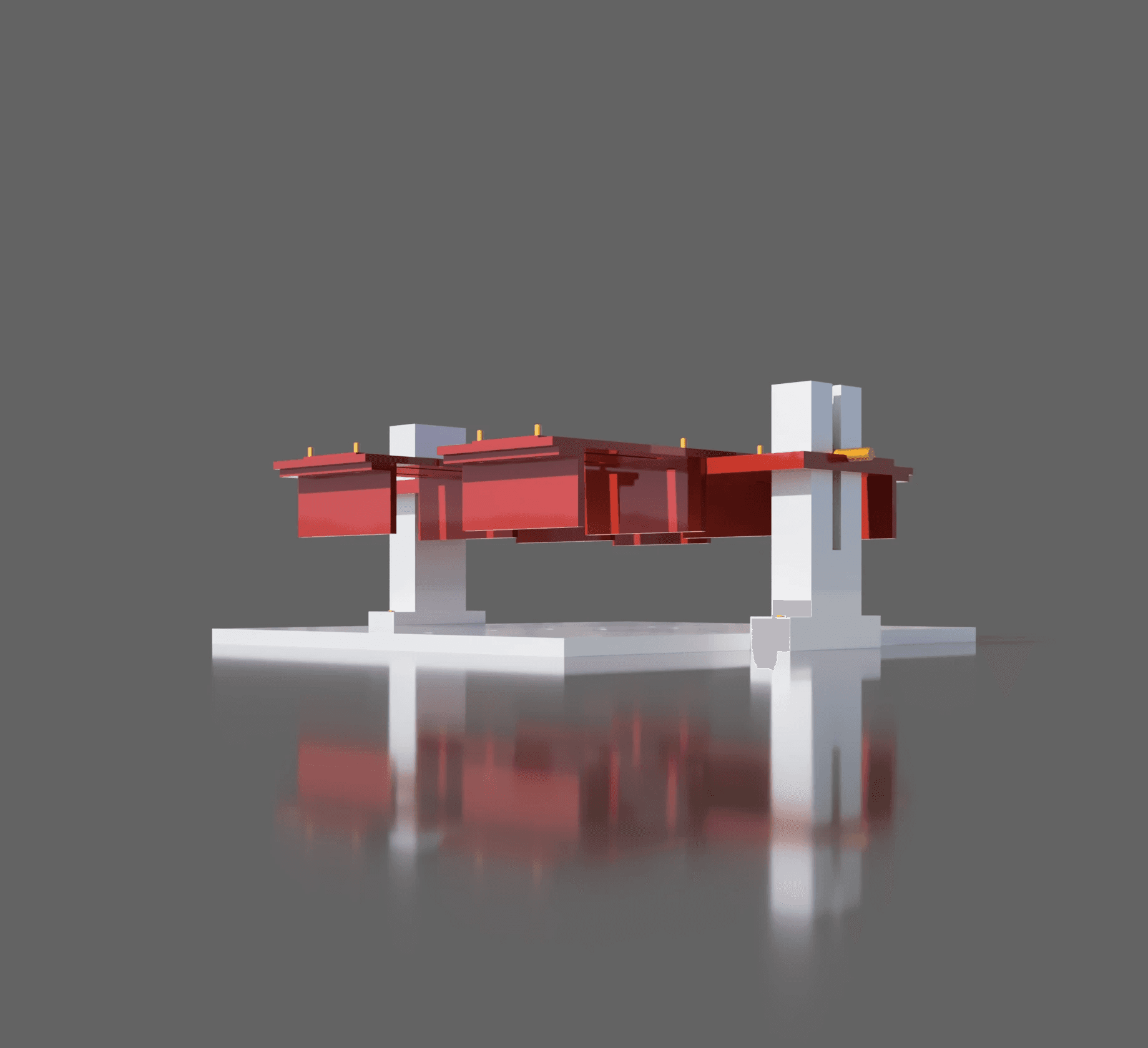

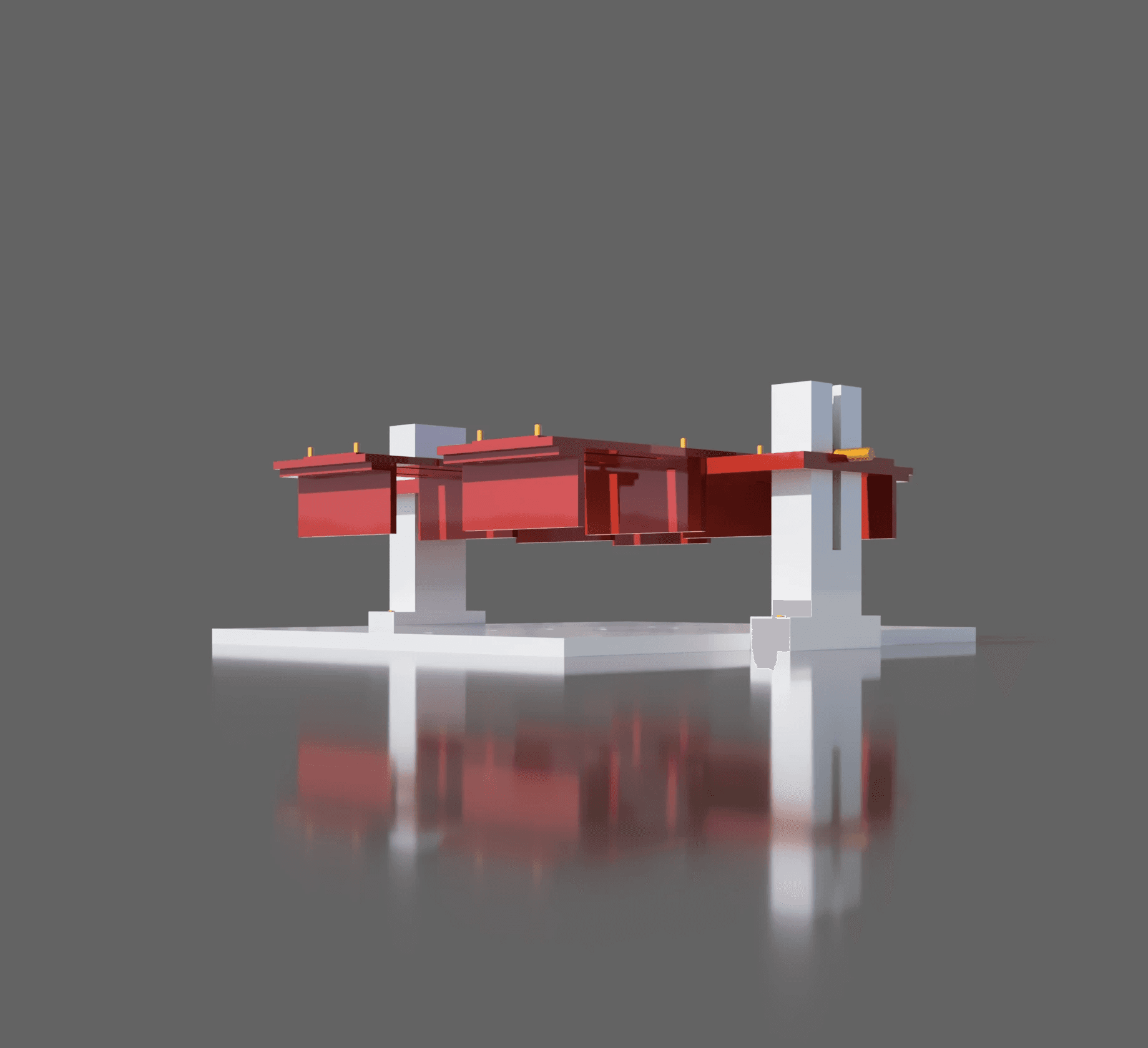

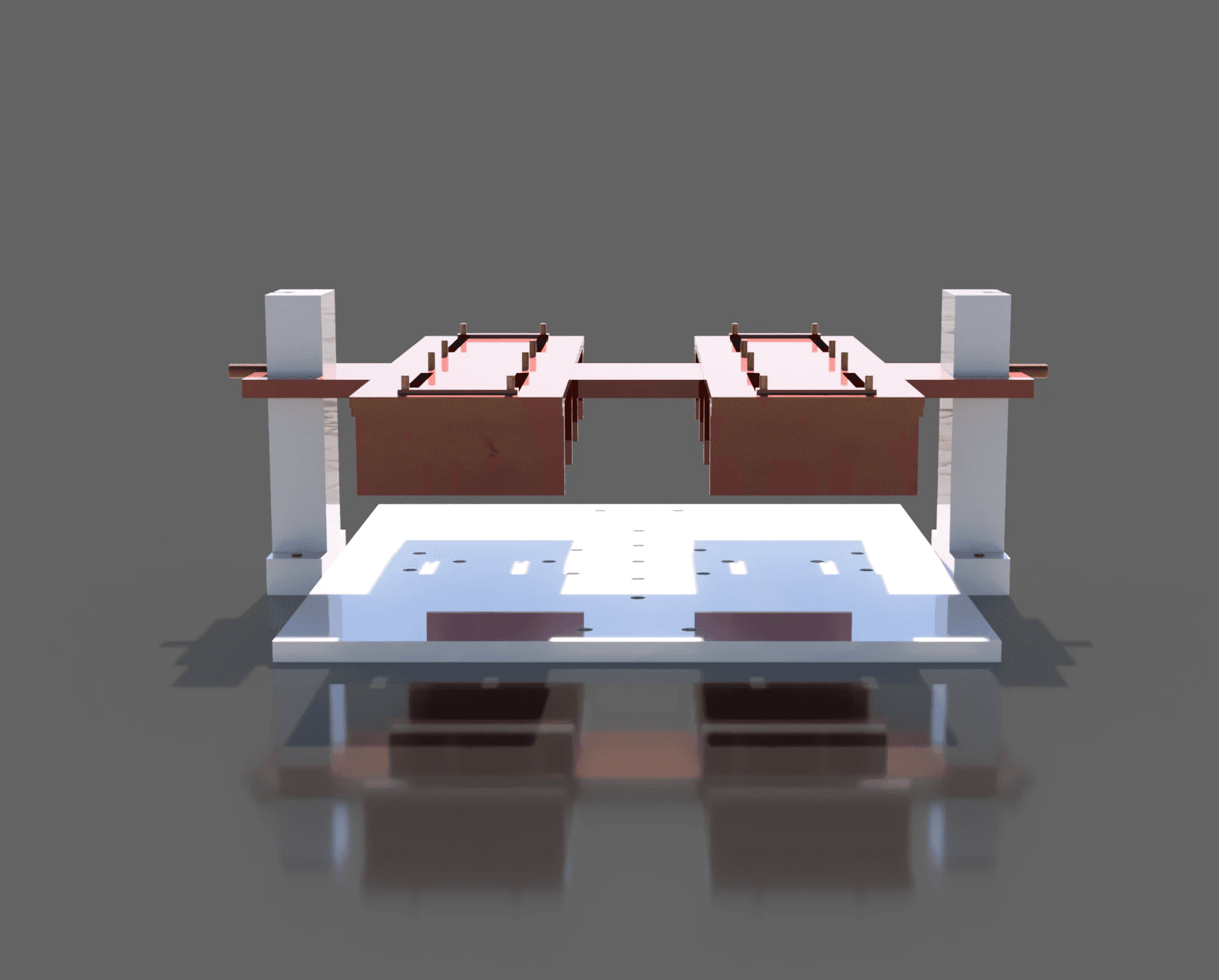

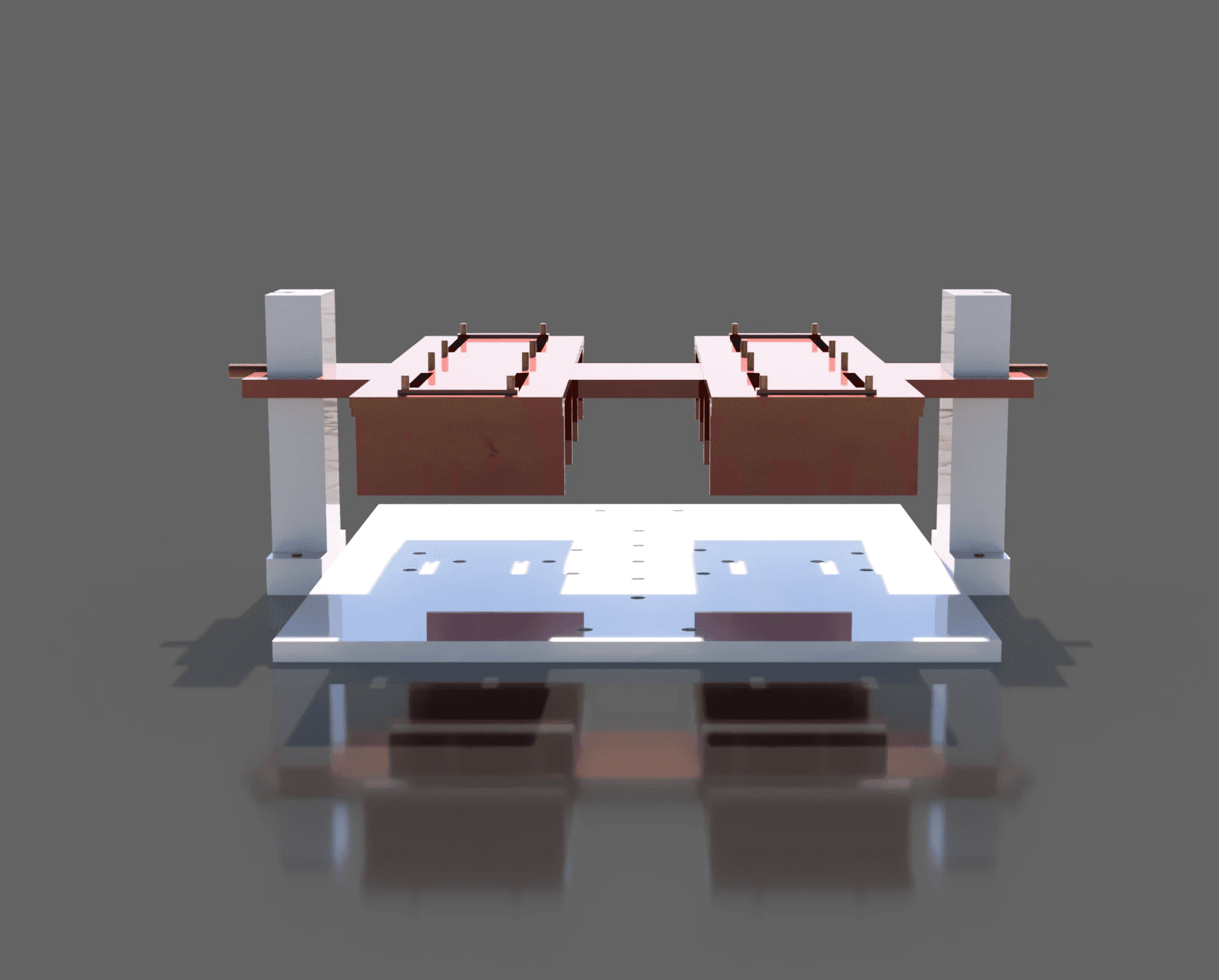

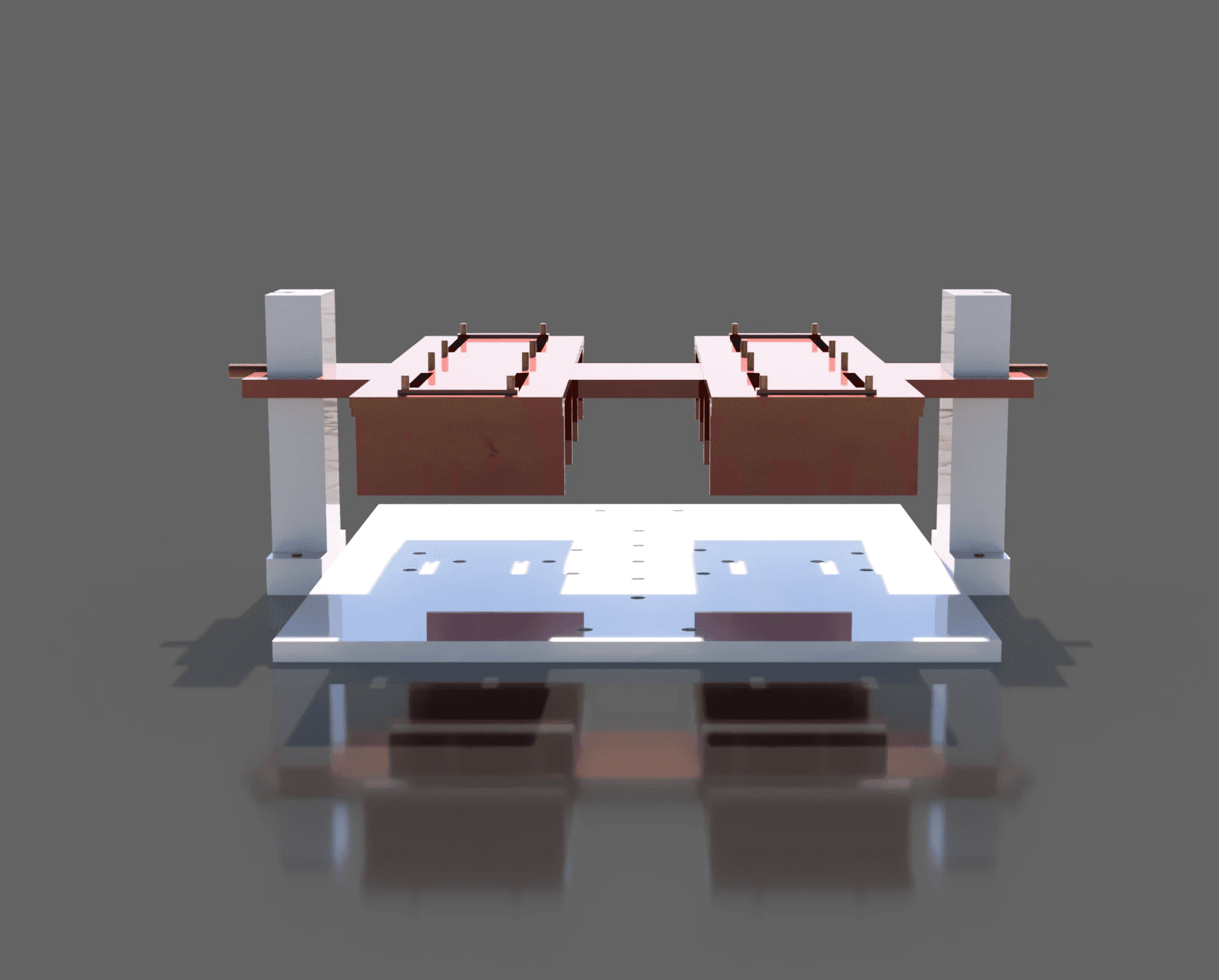

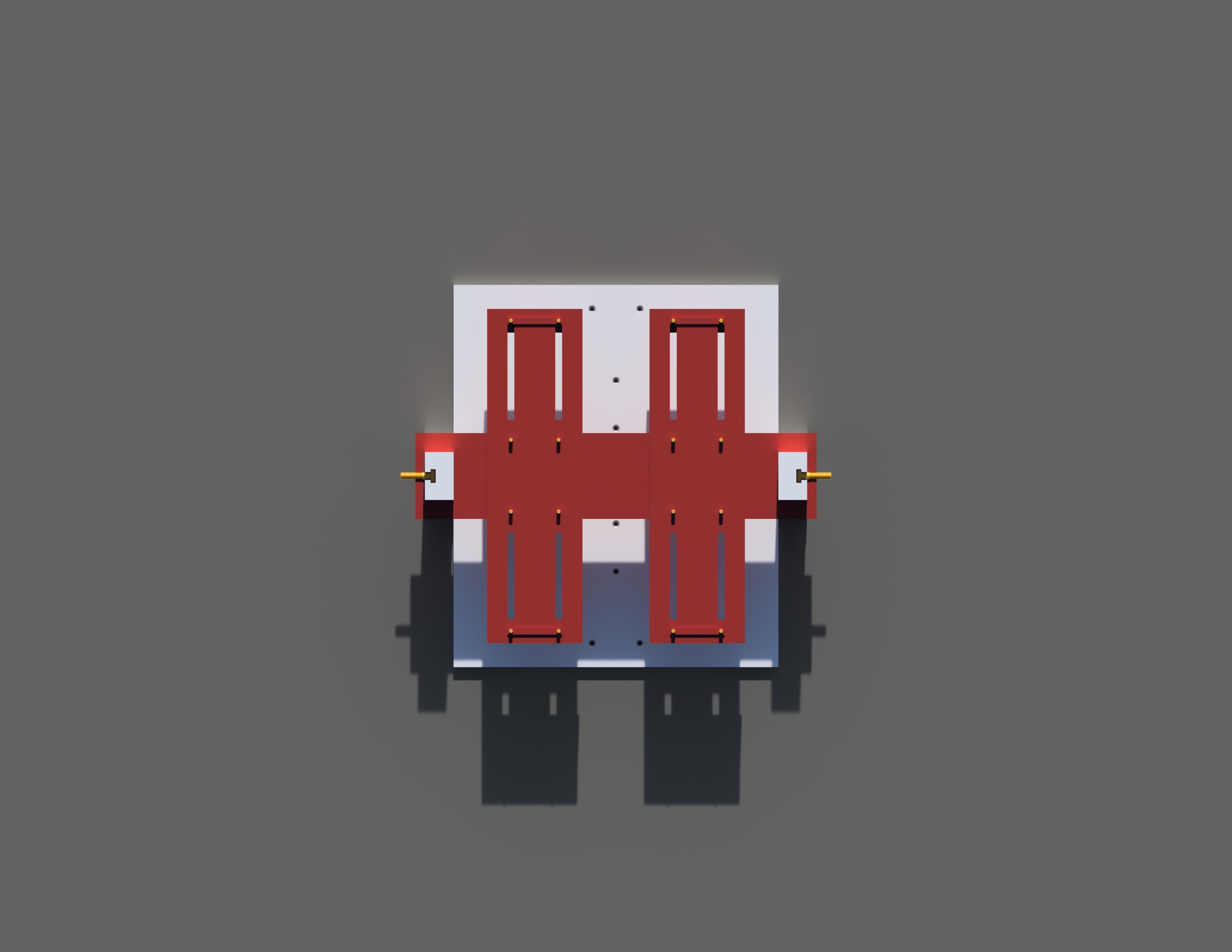

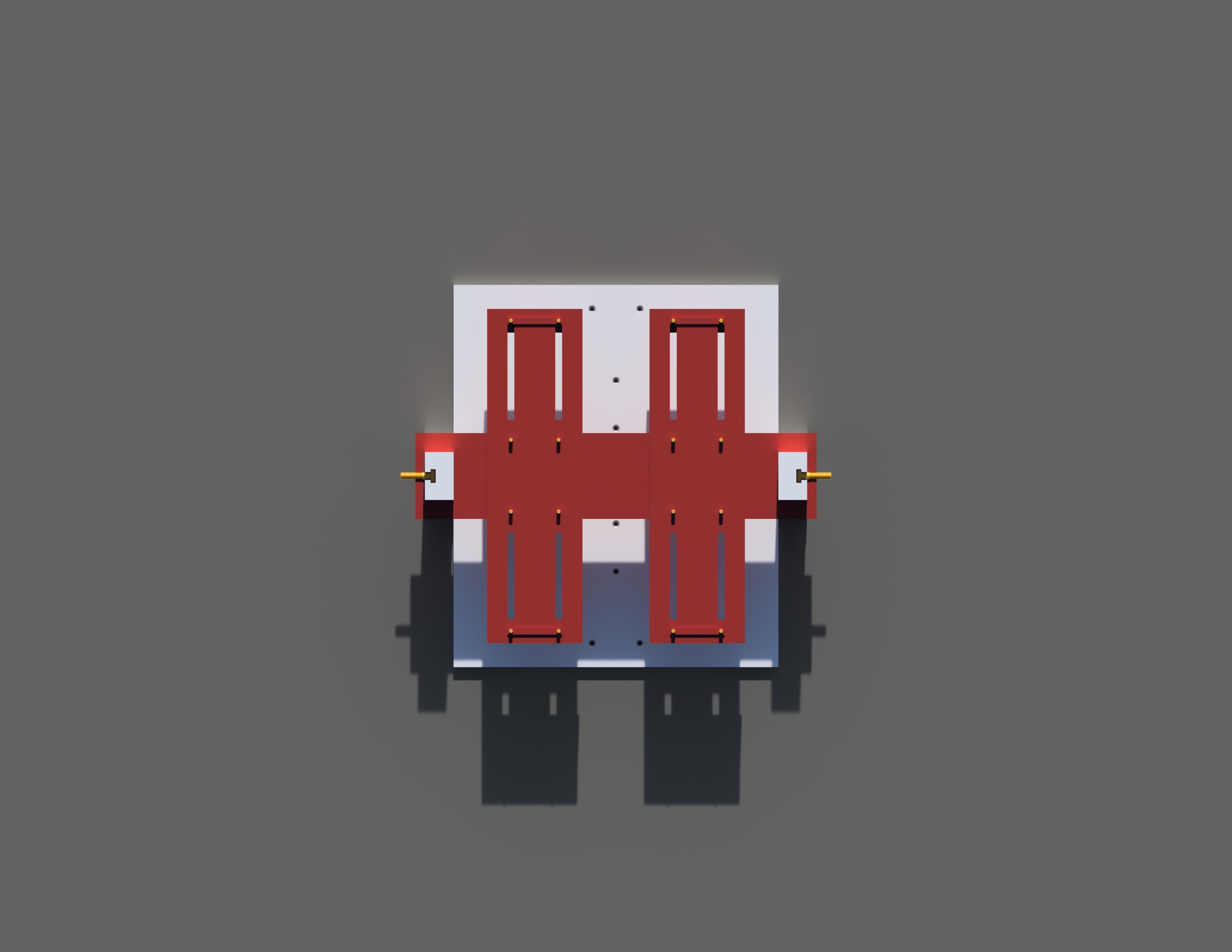

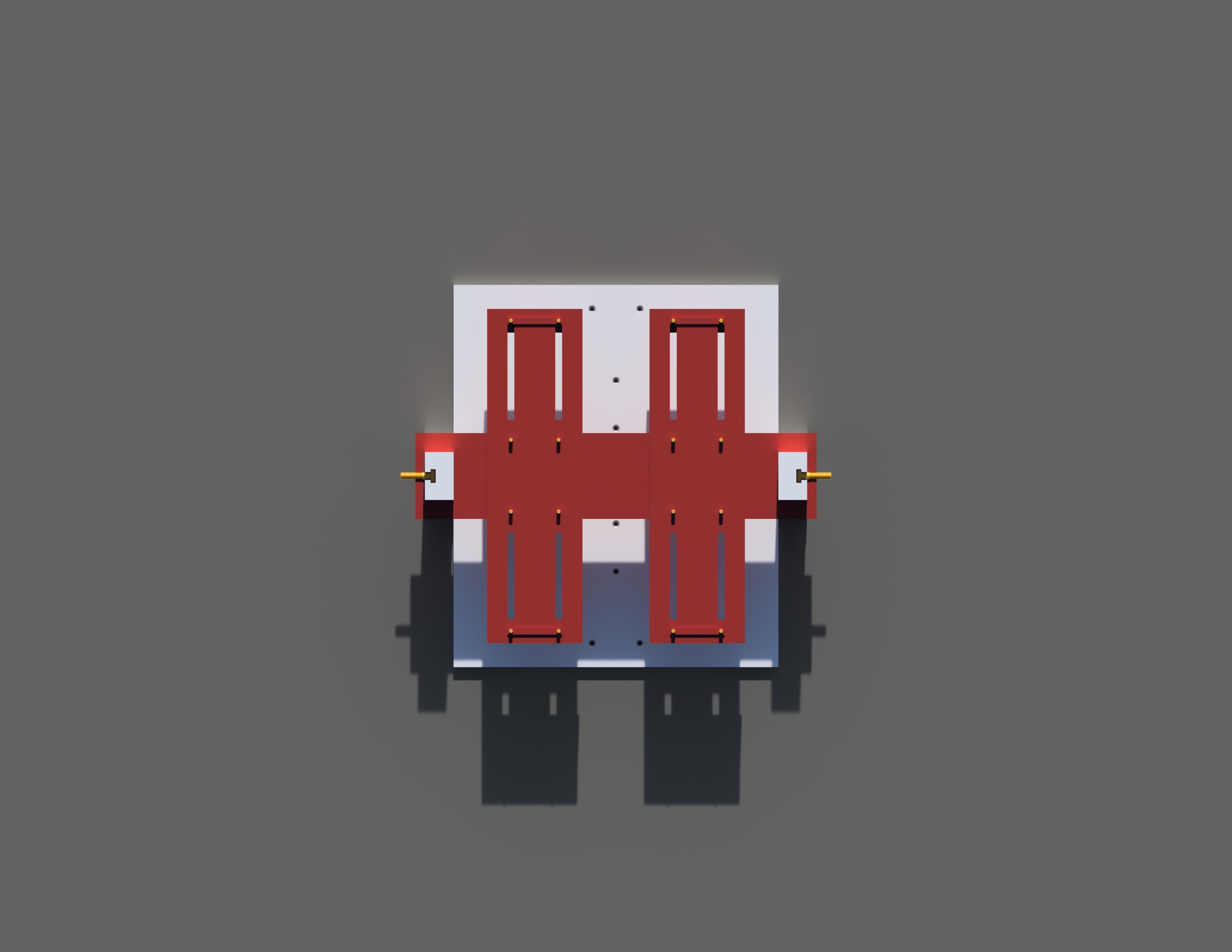

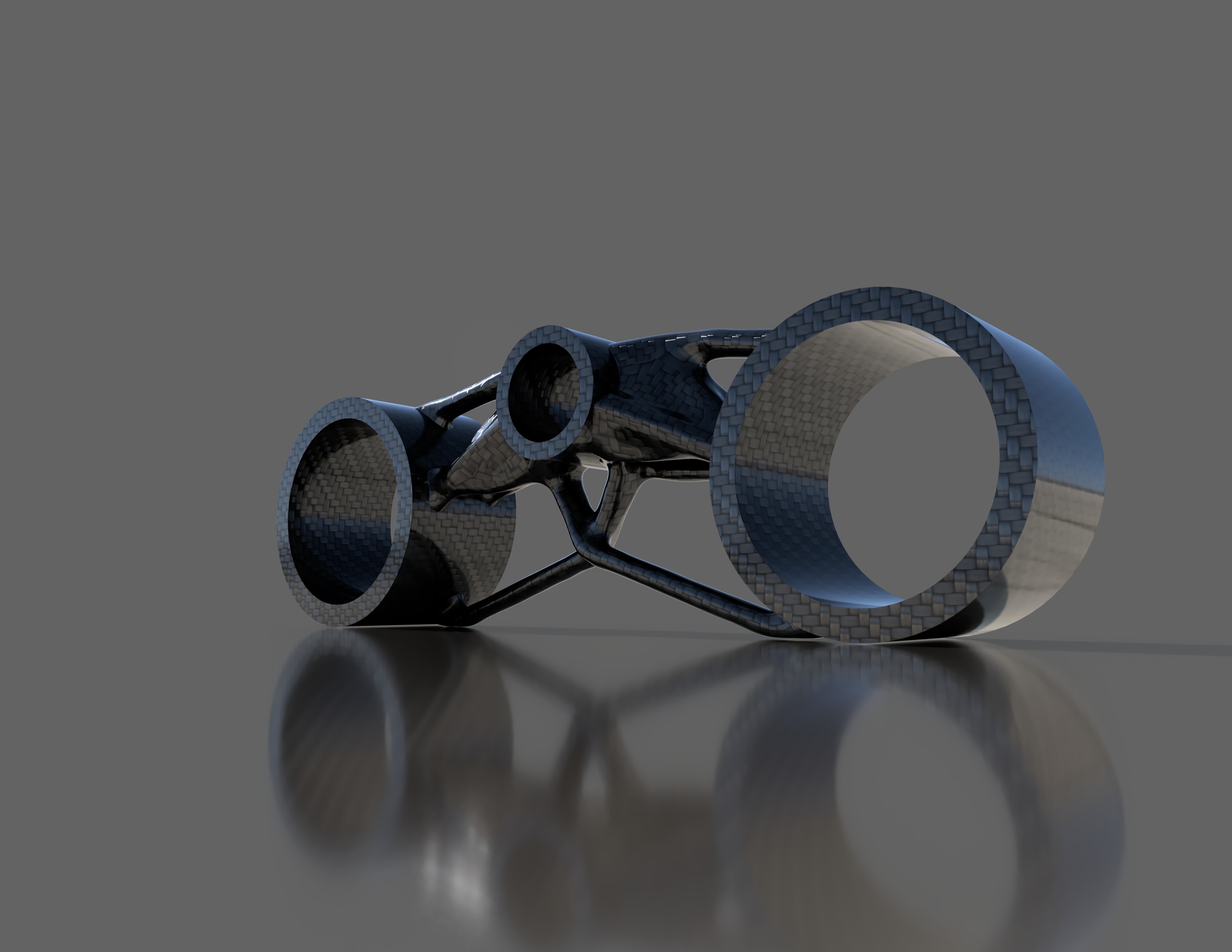

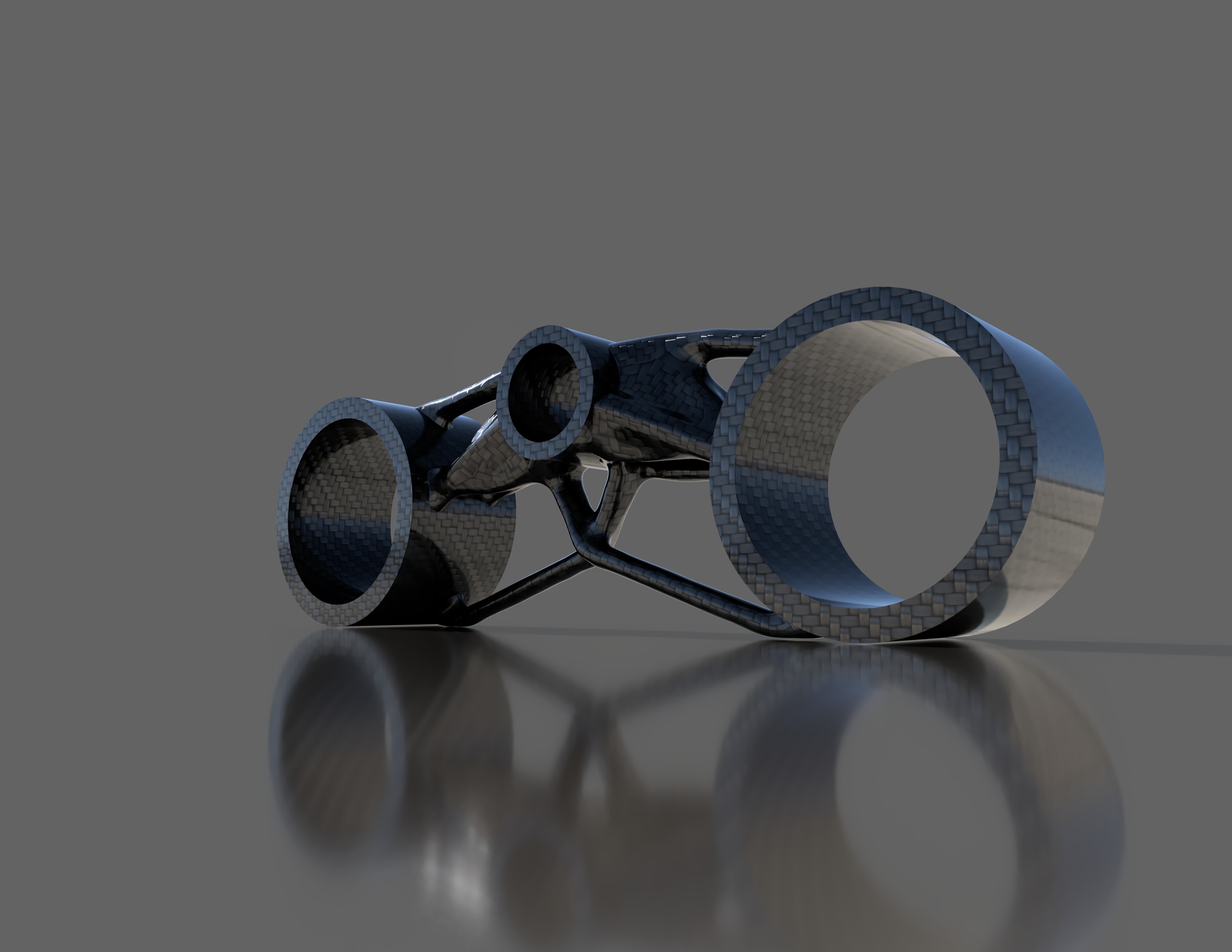

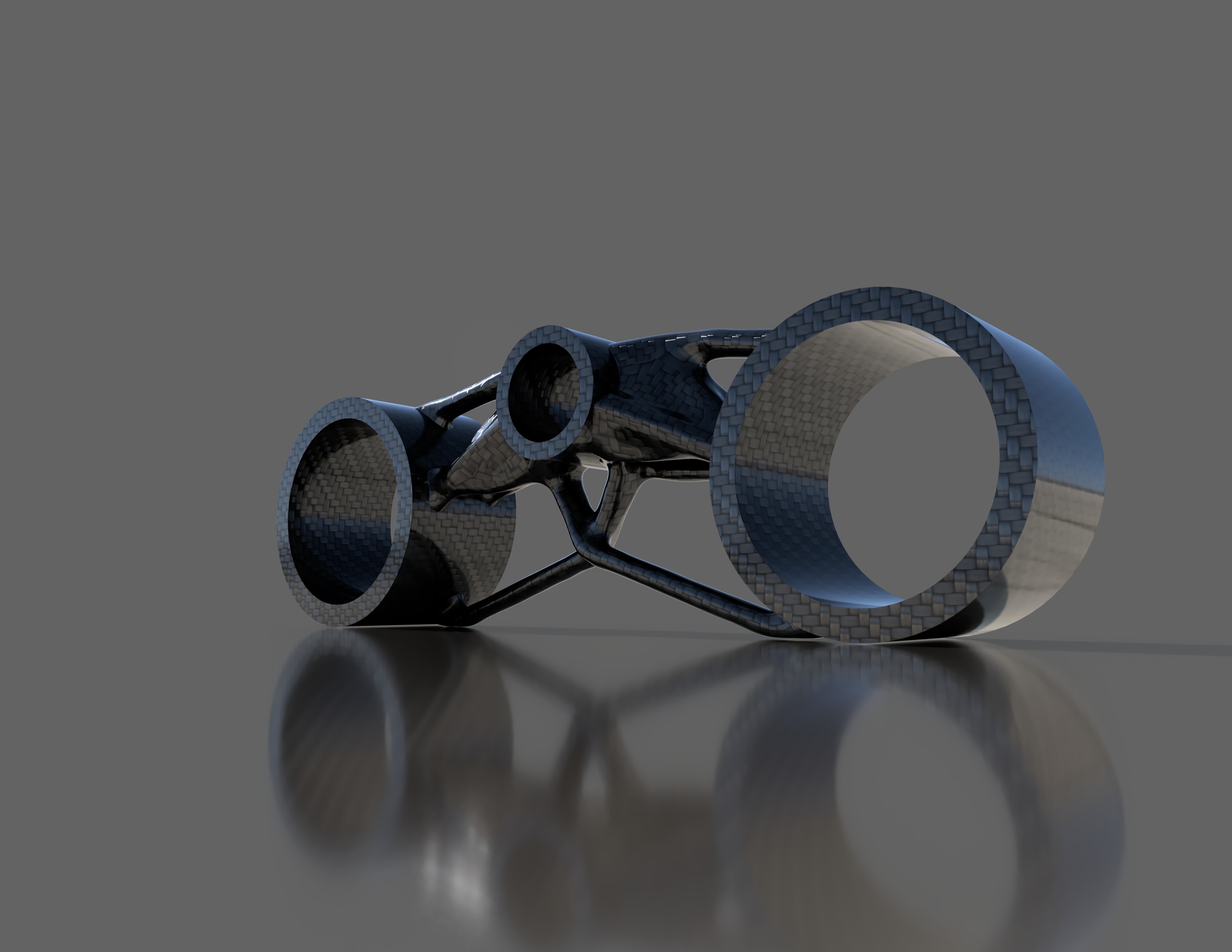

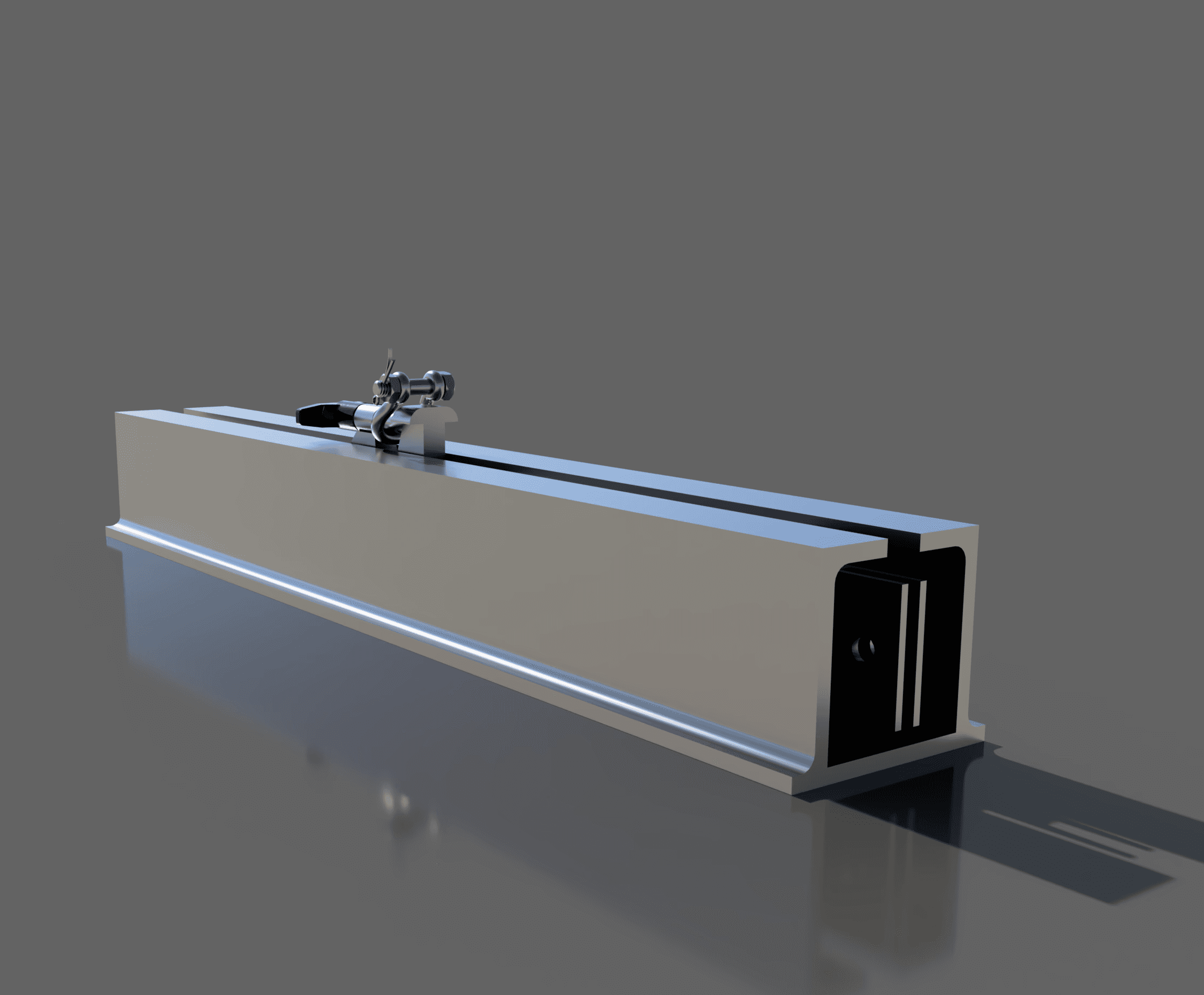

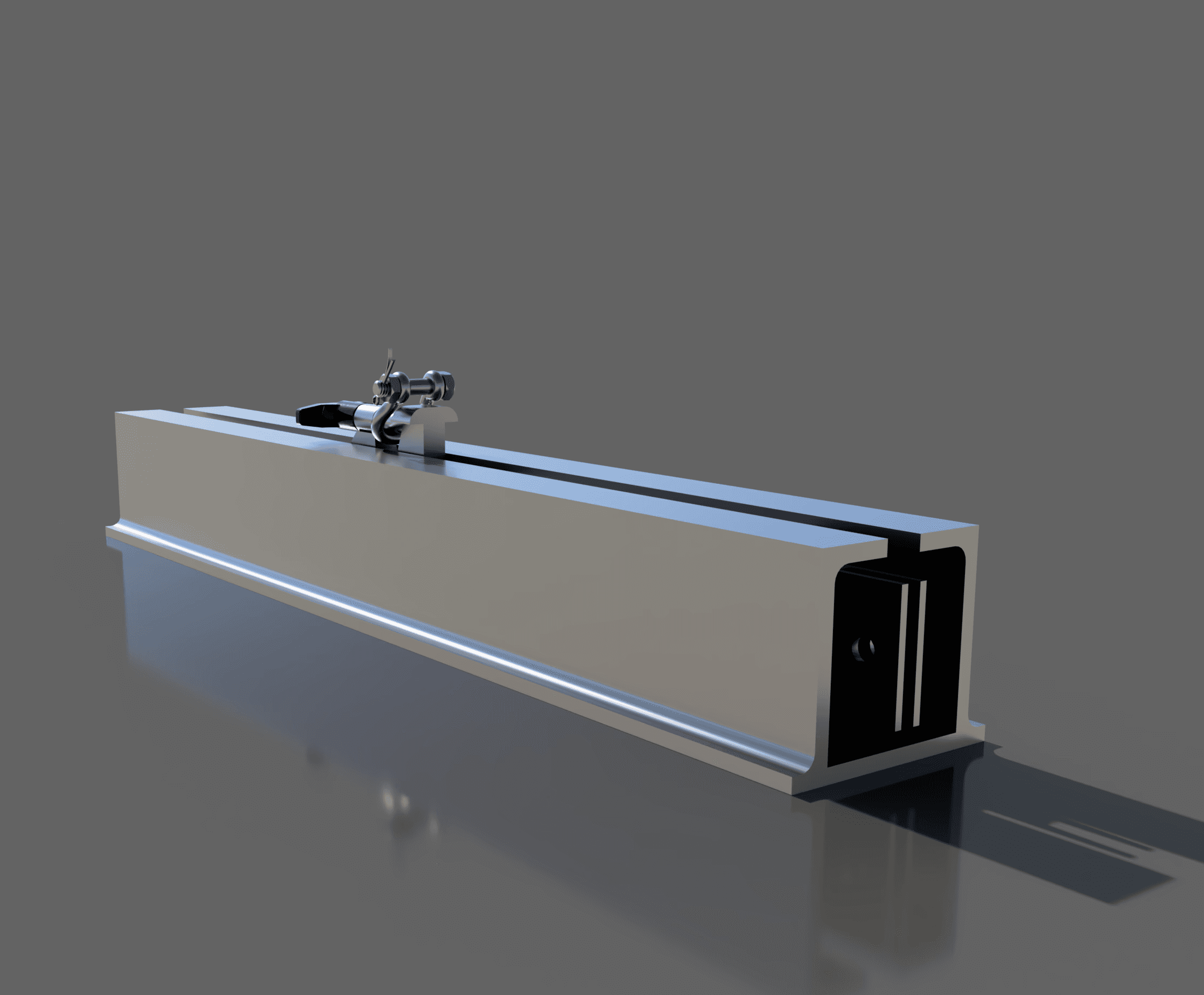

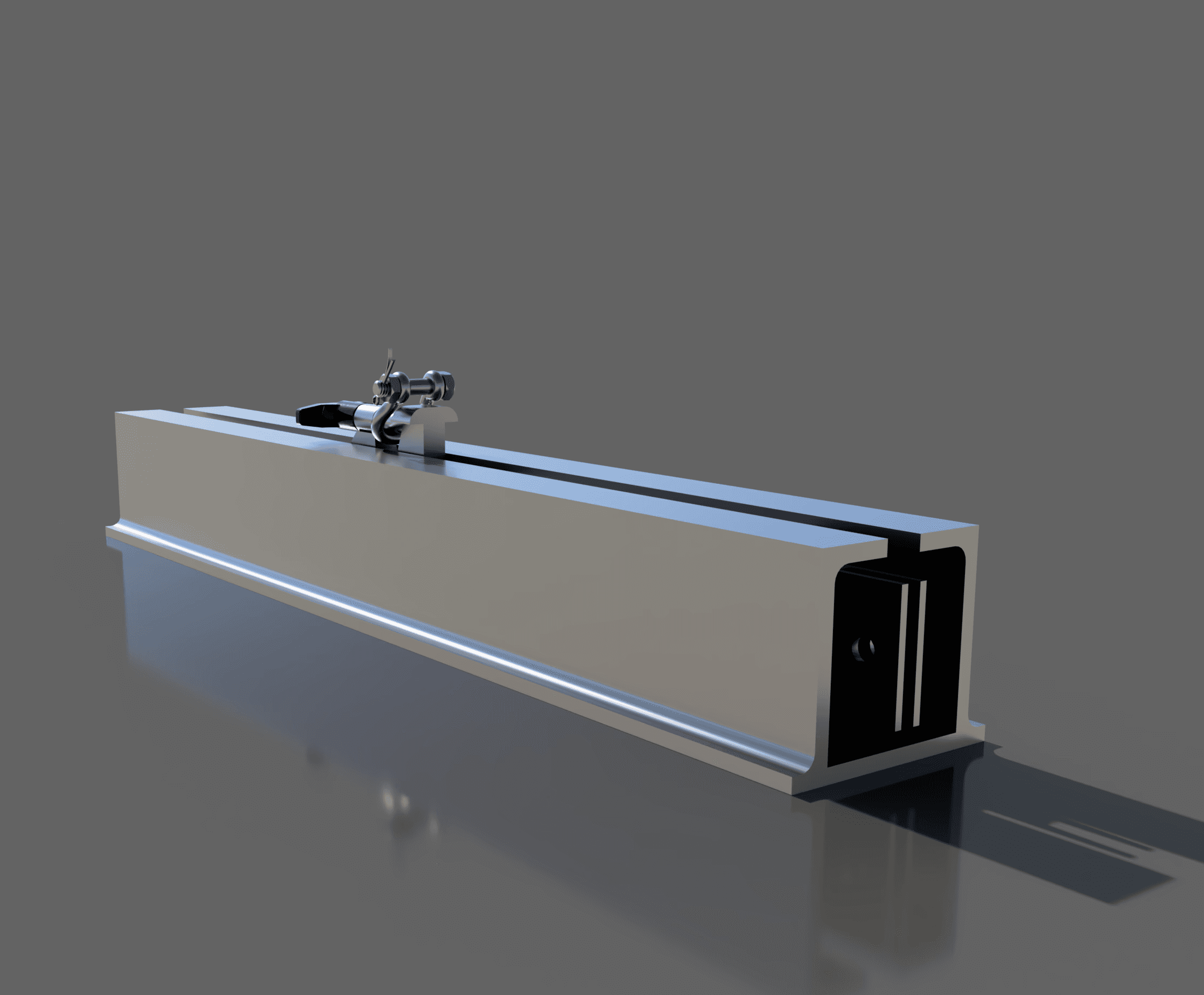

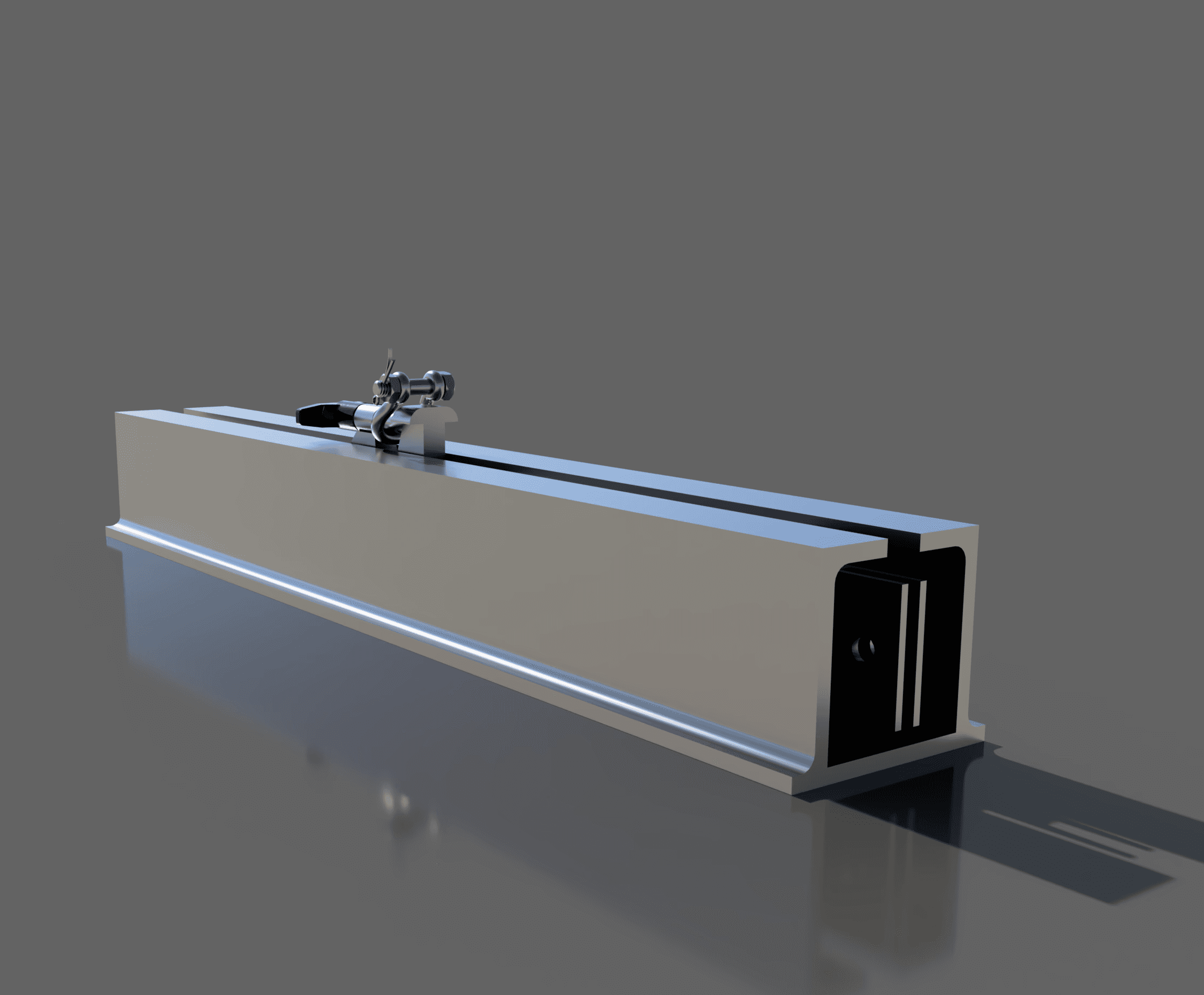

LRU Vibration Fixture

LRU Vibration Fixture

This project involved the design and delivery of a custom vibration fixture used for testing Line Replaceable Units (LRUs) at an Indian Air Force Base Repair Depot. Based solely on the vibration bed's dimensions and mounting layout, a fully functional fixture was developed to meet military testing requirements.

Duration

8 Months

Year

2024

Category

Designing & Simulation

Research

Research

The process began by studying the vibration bed’s hole layout, standard testing procedures and the typical mass and mounting configurations of LRUs. Reference was taken from MIL-STD guidelines to ensure compatibility with defense-grade testing requirements and fixture stability under dynamic loading.

The process began by studying the vibration bed’s hole layout, standard testing procedures and the typical mass and mounting configurations of LRUs. Reference was taken from MIL-STD guidelines to ensure compatibility with defense-grade testing requirements and fixture stability under dynamic loading.

Research

The process began by studying the vibration bed’s hole layout, standard testing procedures and the typical mass and mounting configurations of LRUs. Reference was taken from MIL-STD guidelines to ensure compatibility with defense-grade testing requirements and fixture stability under dynamic loading.

Design

Design

The fixture was designed in 3D CAD to align precisely with the vibration bed’s hole pattern, while allowing flexible mounting options for various LRU sizes. The structure was optimized for stiffness and balance to minimize unwanted resonance and ensure accurate test results.

The fixture was designed in 3D CAD to align precisely with the vibration bed’s hole pattern, while allowing flexible mounting options for various LRU sizes. The structure was optimized for stiffness and balance to minimize unwanted resonance and ensure accurate test results.

Design

The fixture was designed in 3D CAD to align precisely with the vibration bed’s hole pattern, while allowing flexible mounting options for various LRU sizes. The structure was optimized for stiffness and balance to minimize unwanted resonance and ensure accurate test results.

Development

Development

After finalizing the design, fabrication was carried out using precision machining to ensure alignment and durability. The fixture was assembled, inspected and delivered to the BRD for direct integration with the existing vibration bed.

After finalizing the design, fabrication was carried out using precision machining to ensure alignment and durability. The fixture was assembled, inspected and delivered to the BRD for direct integration with the existing vibration bed.

Development

After finalizing the design, fabrication was carried out using precision machining to ensure alignment and durability. The fixture was assembled, inspected and delivered to the BRD for direct integration with the existing vibration bed.

Concept

Concept

The core concept was to create a versatile, robust fixture that could securely hold various LRUs during high-frequency vibration tests. Emphasis was placed on precise alignment, structural rigidity and ease of installation to meet stringent defense testing standards.

The core concept was to create a versatile, robust fixture that could securely hold various LRUs during high-frequency vibration tests. Emphasis was placed on precise alignment, structural rigidity and ease of installation to meet stringent defense testing standards.

Concept

The core concept was to create a versatile, robust fixture that could securely hold various LRUs during high-frequency vibration tests. Emphasis was placed on precise alignment, structural rigidity and ease of installation to meet stringent defense testing standards.

More Works More Works

More Works More Works

Motorcycle Triple Clamp

Generative Design

2024

2024

Motorcycle Triple Clamp

Generative Design

2024

2024

Motorcycle Triple Clamp

Generative Design

2024

2024

Motorcycle Triple Clamp

Generative Design

2024

2024

Skate and Rail Assembly

Designing & Simulation

2025

2025

Skate and Rail Assembly

Designing & Simulation

2025

2025

Skate and Rail Assembly

Designing & Simulation

2025

2025

Skate and Rail Assembly

Designing & Simulation

2025

2025

©2024 MANDRO DESIGN

GO BACK TO TOP

©2024 MANDRO DESIGN

GO BACK TO TOP