LOCAL/

10:47:45 AM

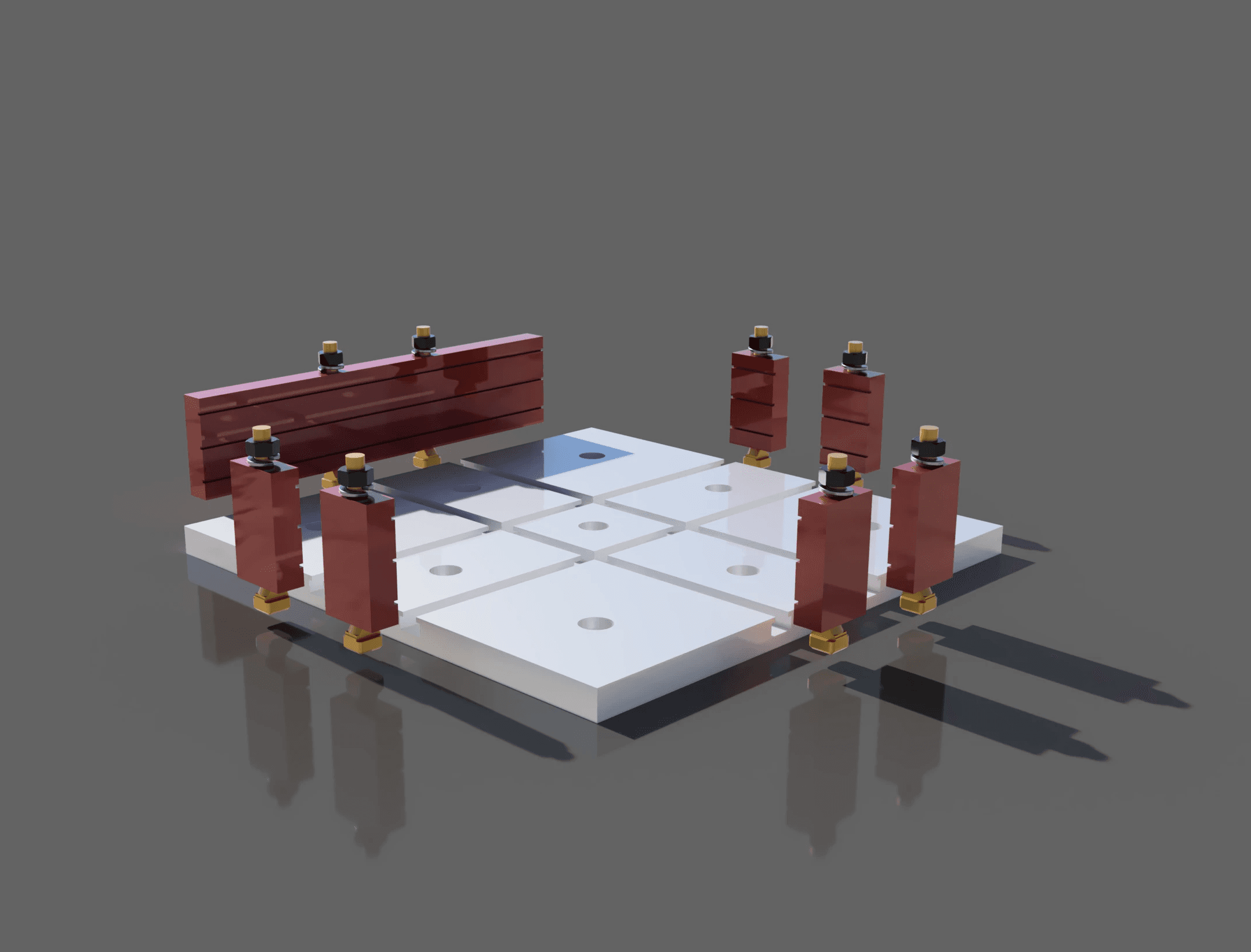

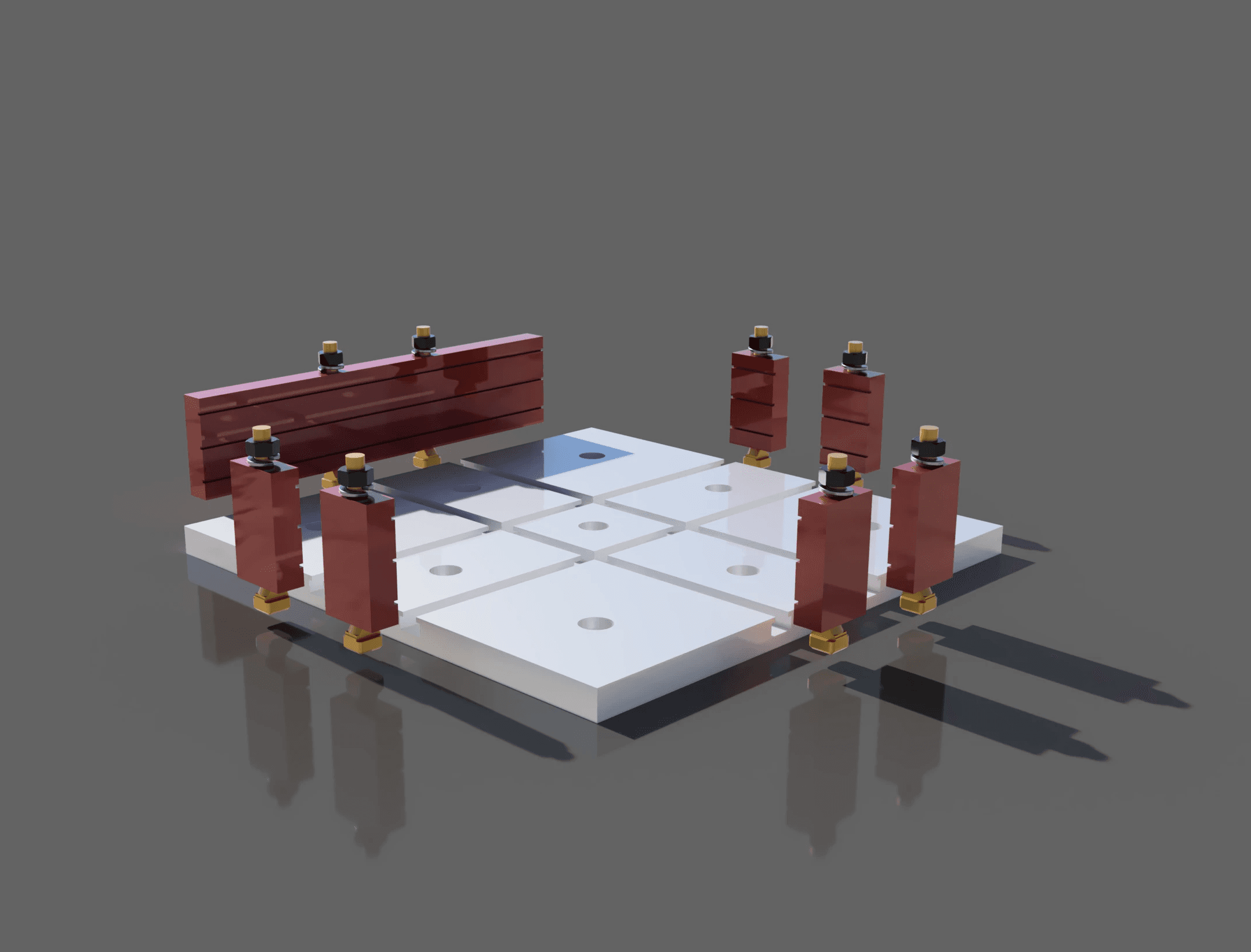

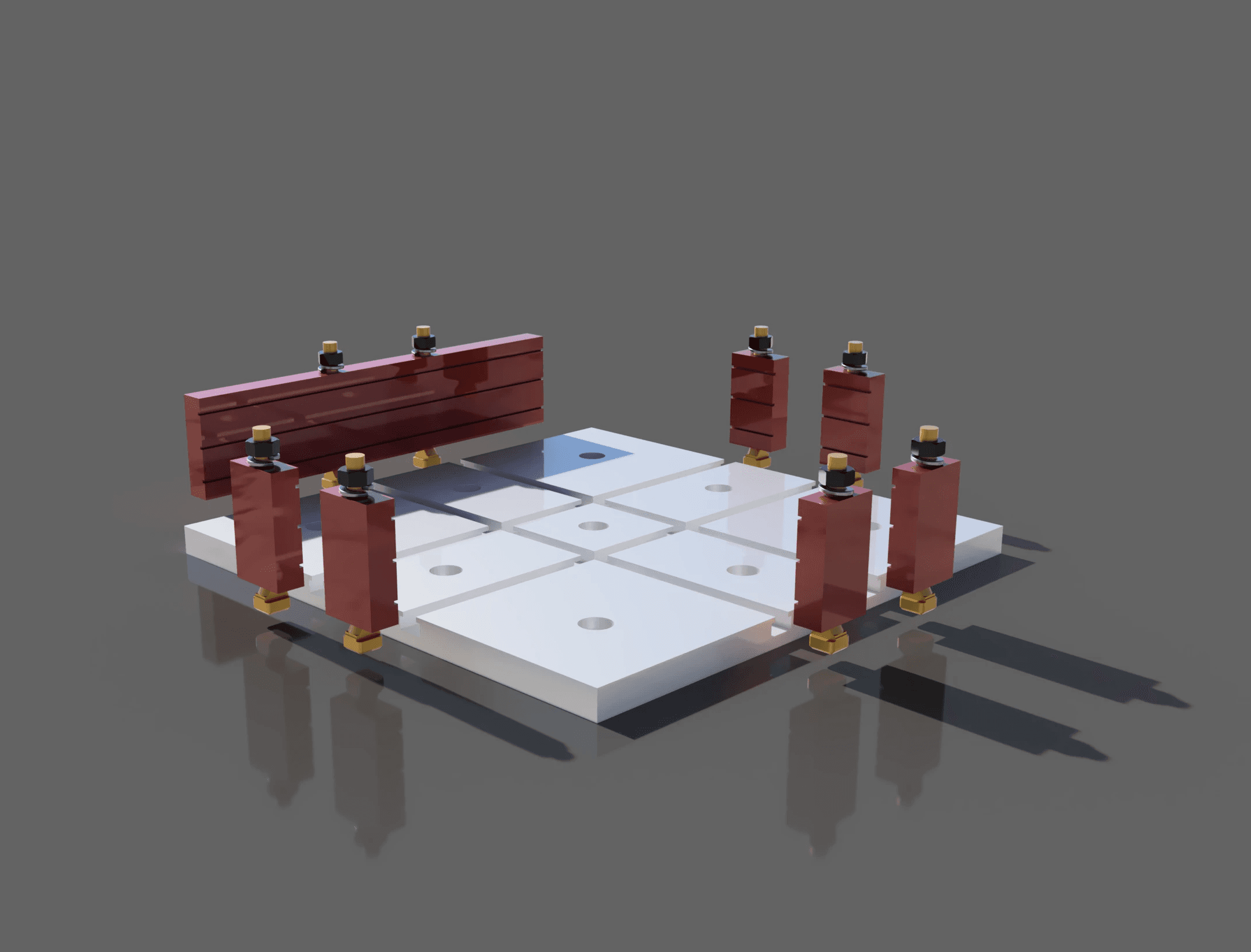

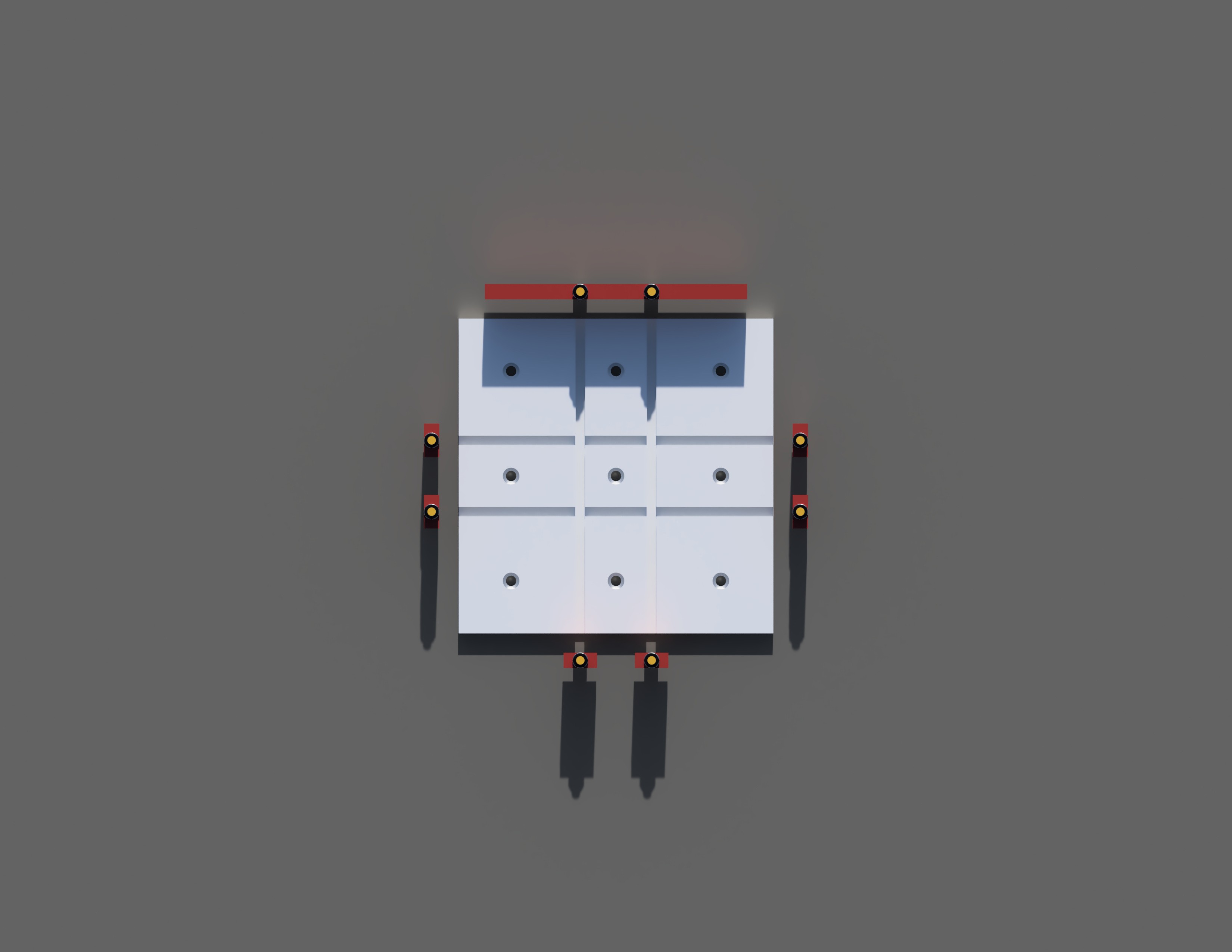

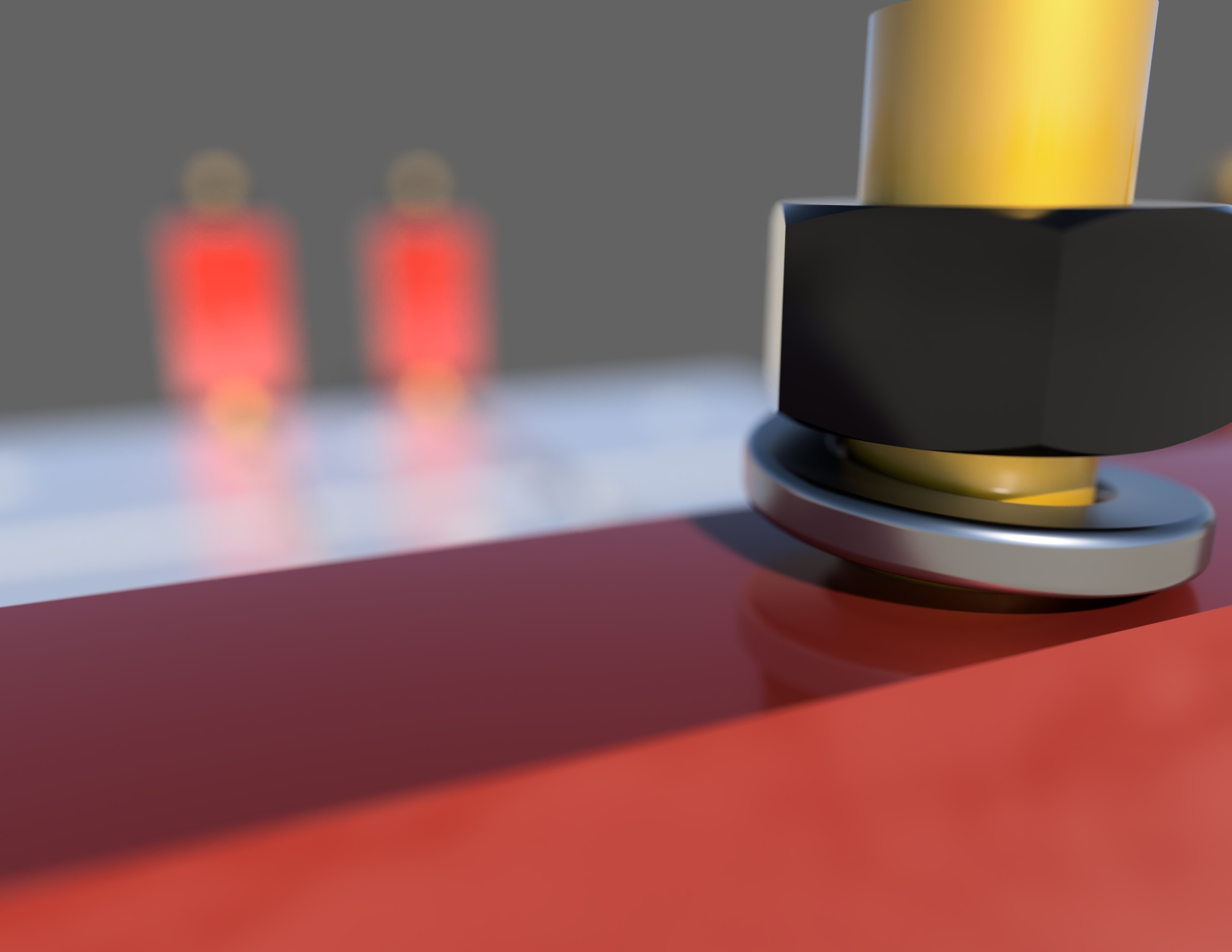

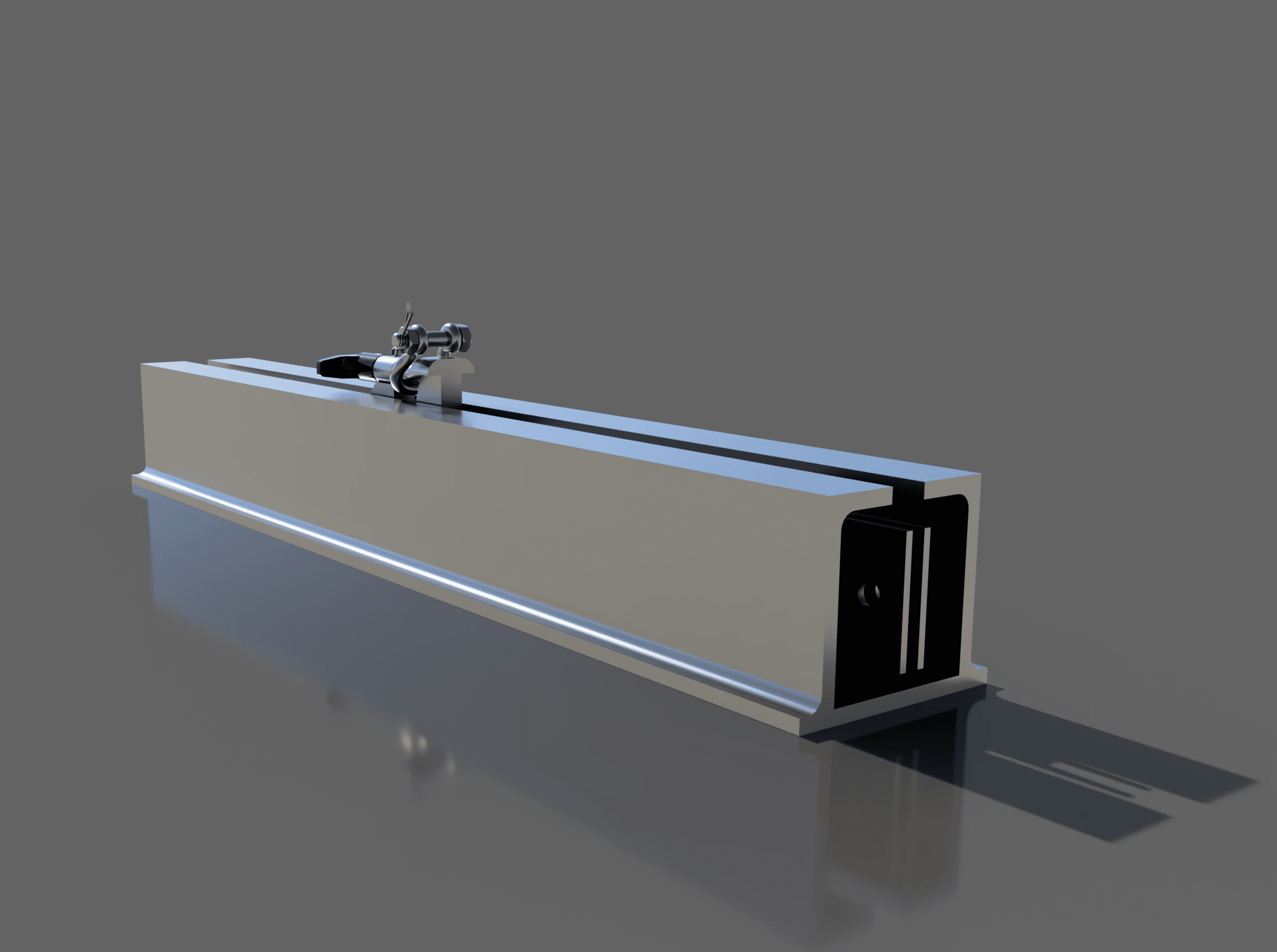

PCB Vibration Fixture

PCB Vibration Fixture

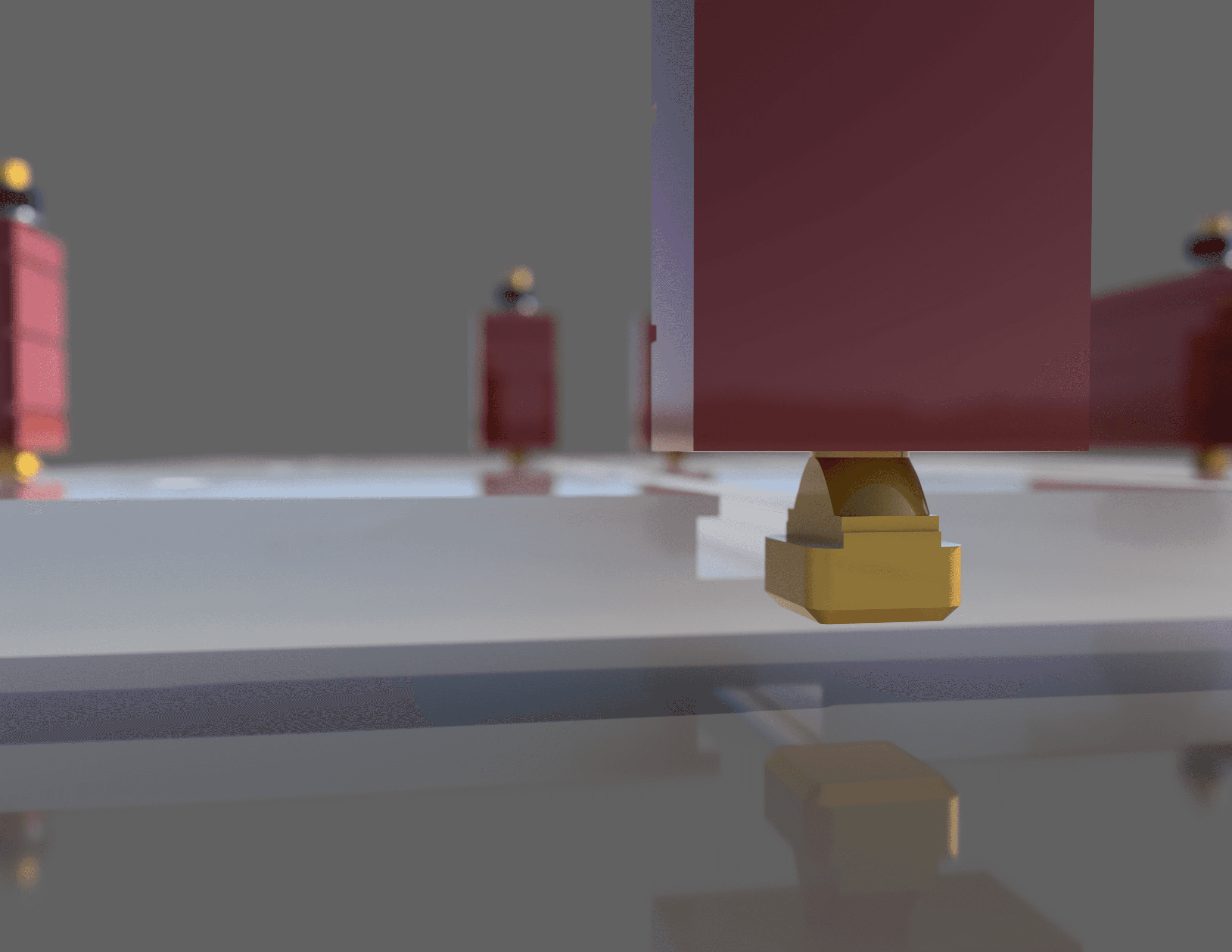

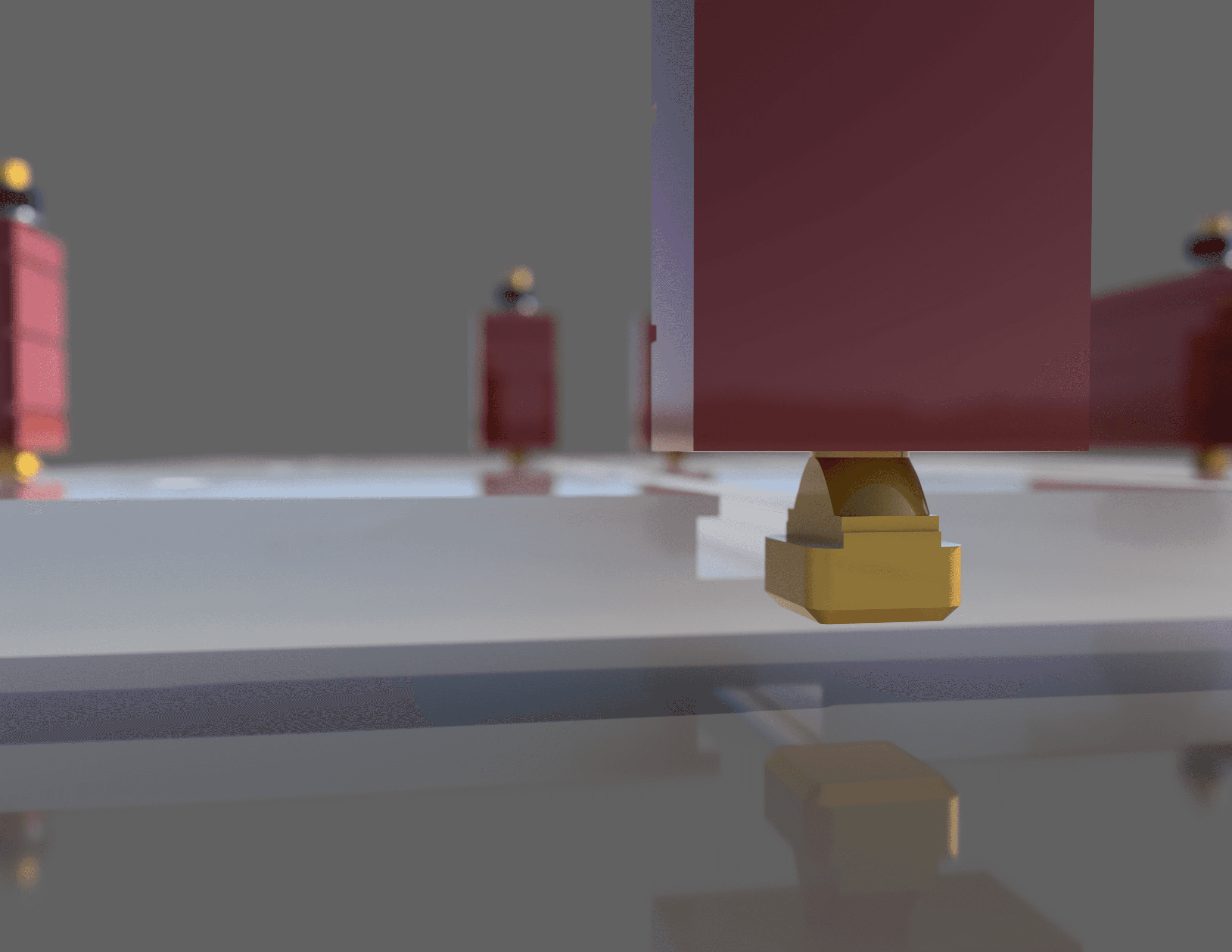

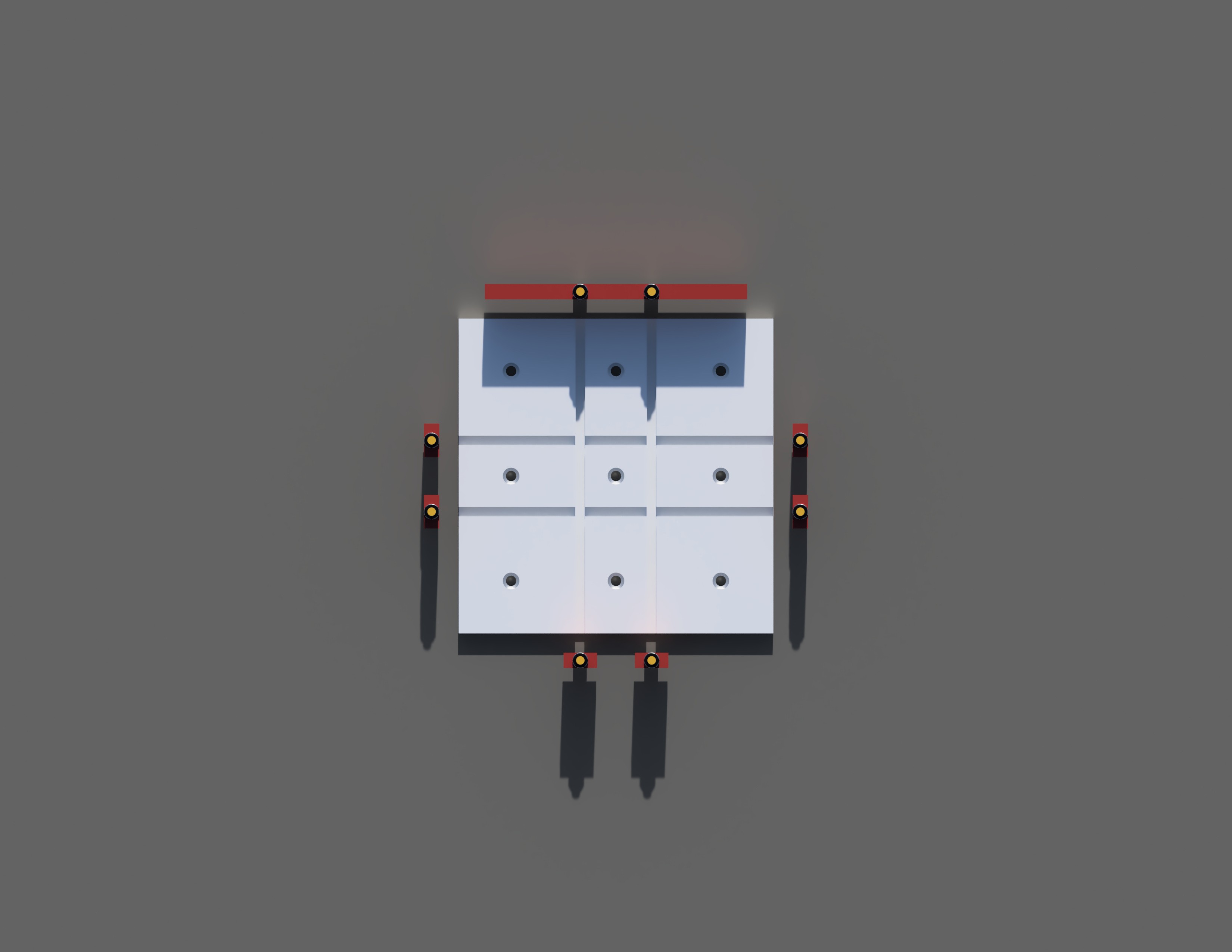

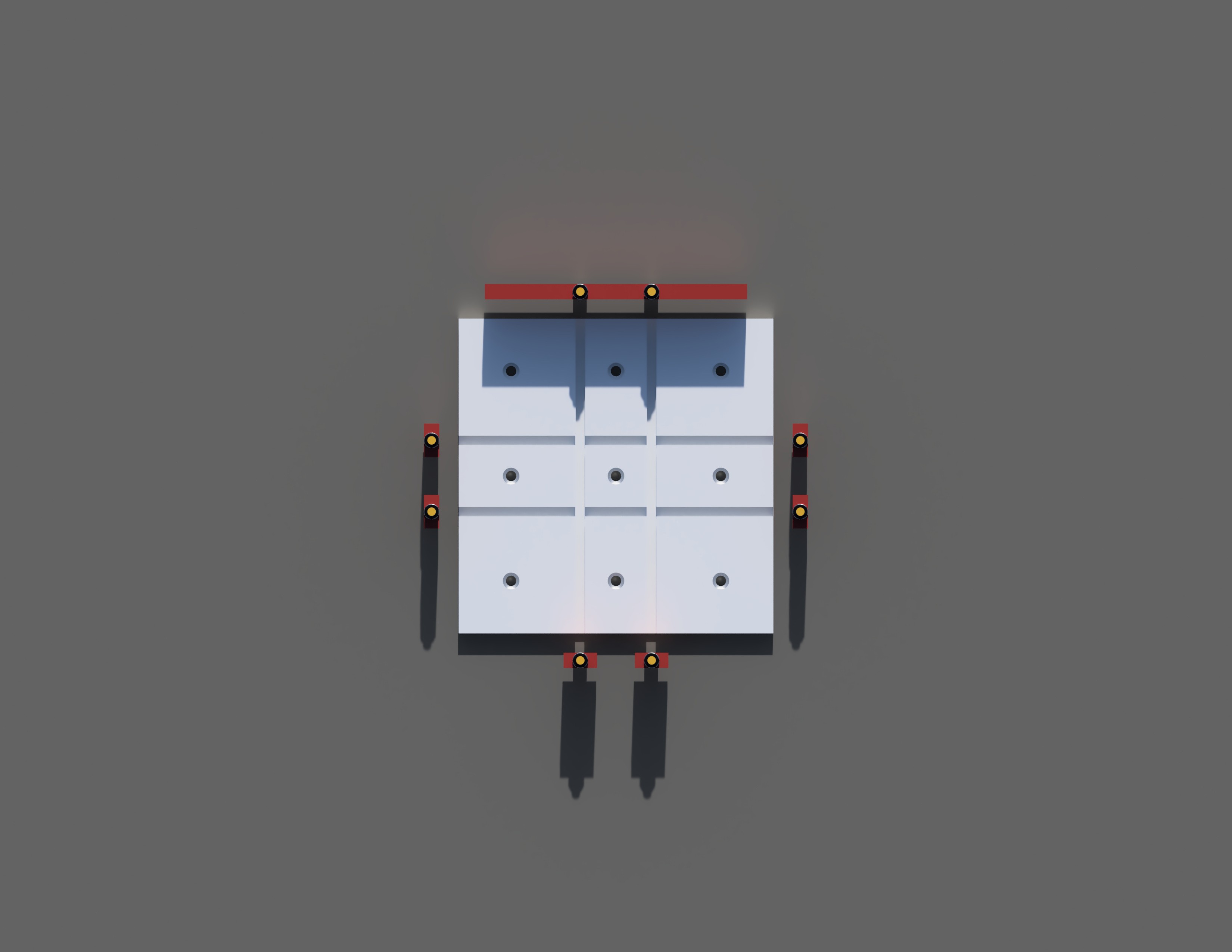

Designed and delivered a custom vibration fixture specifically for printed circuit boards (PCBs) used in Line Replaceable Units (LRUs) at an Indian Air Force Base Repair Depot. Based on the vibration bed’s mounting dimensions, the fixture ensured secure, reliable testing of sensitive electronic components.

Duration

7 months

Year

2024

Category

Designing & Simulation

Research

Research

The project began with analyzing the vibration bed’s hole layout and the unique requirements for securing delicate PCBs during testing. MIL-STD standards and electronic component sensitivity were considered to define fixture stability and vibration isolation parameters.

The project began with analyzing the vibration bed’s hole layout and the unique requirements for securing delicate PCBs during testing. MIL-STD standards and electronic component sensitivity were considered to define fixture stability and vibration isolation parameters.

Research

The project began with analyzing the vibration bed’s hole layout and the unique requirements for securing delicate PCBs during testing. MIL-STD standards and electronic component sensitivity were considered to define fixture stability and vibration isolation parameters.

Design

Design

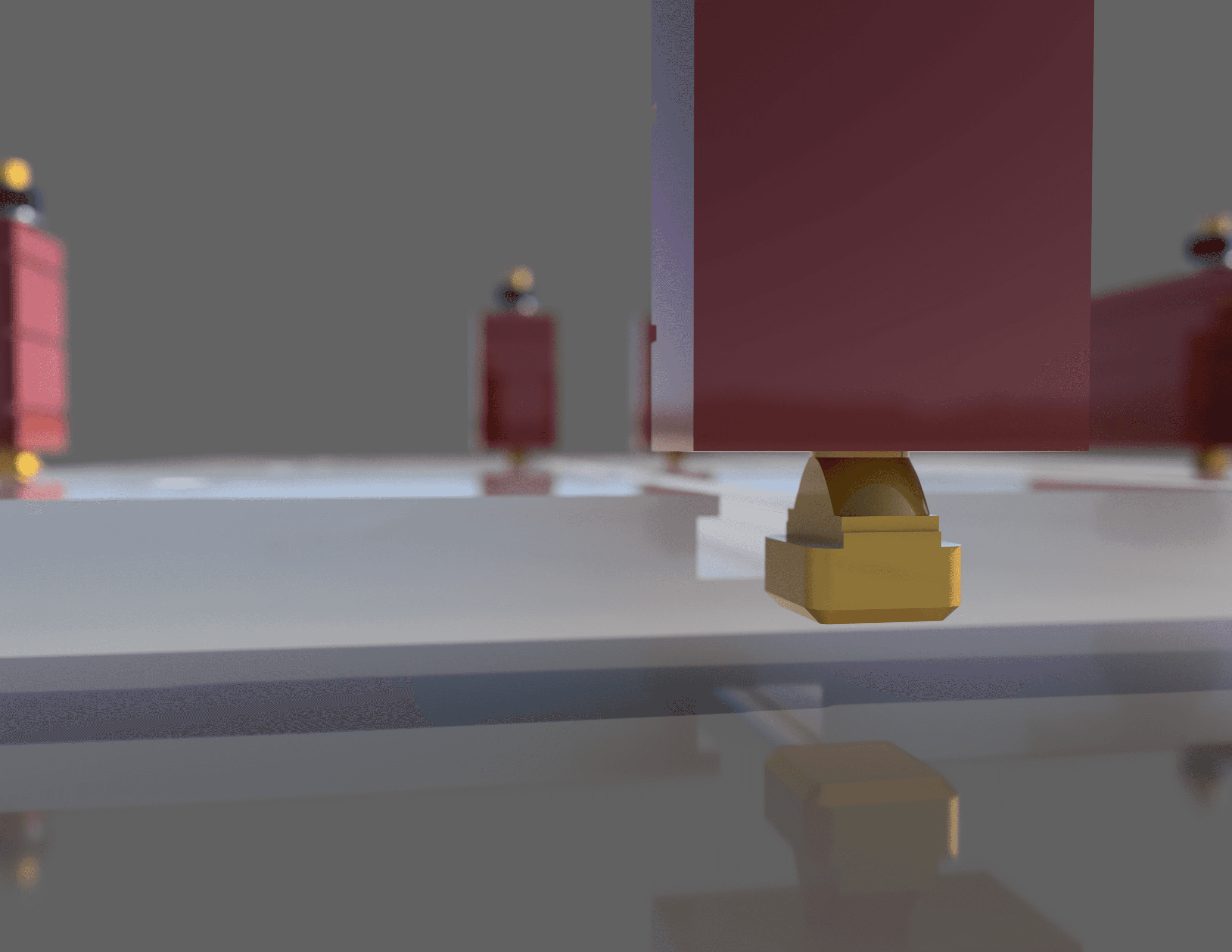

The fixture was designed to fit precisely on the vibration bed, incorporating flexible mounting points to accommodate various PCB sizes and layouts. The design prioritized minimizing transmission of excessive vibration to sensitive components while maintaining firm support during testing.

The fixture was designed to fit precisely on the vibration bed, incorporating flexible mounting points to accommodate various PCB sizes and layouts. The design prioritized minimizing transmission of excessive vibration to sensitive components while maintaining firm support during testing.

Design

The fixture was designed to fit precisely on the vibration bed, incorporating flexible mounting points to accommodate various PCB sizes and layouts. The design prioritized minimizing transmission of excessive vibration to sensitive components while maintaining firm support during testing.

Development

Development

The fixture was fabricated with precision machining to ensure accurate alignment and durability. Assembly and quality checks were performed before delivery to the Base Repair Depot.

The fixture was fabricated with precision machining to ensure accurate alignment and durability. Assembly and quality checks were performed before delivery to the Base Repair Depot.

Development

The fixture was fabricated with precision machining to ensure accurate alignment and durability. Assembly and quality checks were performed before delivery to the Base Repair Depot.

Concept

Concept

The design aimed to provide a reliable and adaptable fixture that securely holds PCBs during high-frequency vibration tests. Key considerations included protecting sensitive electronics from excessive stress while ensuring repeatable and accurate testing conditions.

The design aimed to provide a reliable and adaptable fixture that securely holds PCBs during high-frequency vibration tests. Key considerations included protecting sensitive electronics from excessive stress while ensuring repeatable and accurate testing conditions.

Concept

The design aimed to provide a reliable and adaptable fixture that securely holds PCBs during high-frequency vibration tests. Key considerations included protecting sensitive electronics from excessive stress while ensuring repeatable and accurate testing conditions.

More Works More Works

More Works More Works

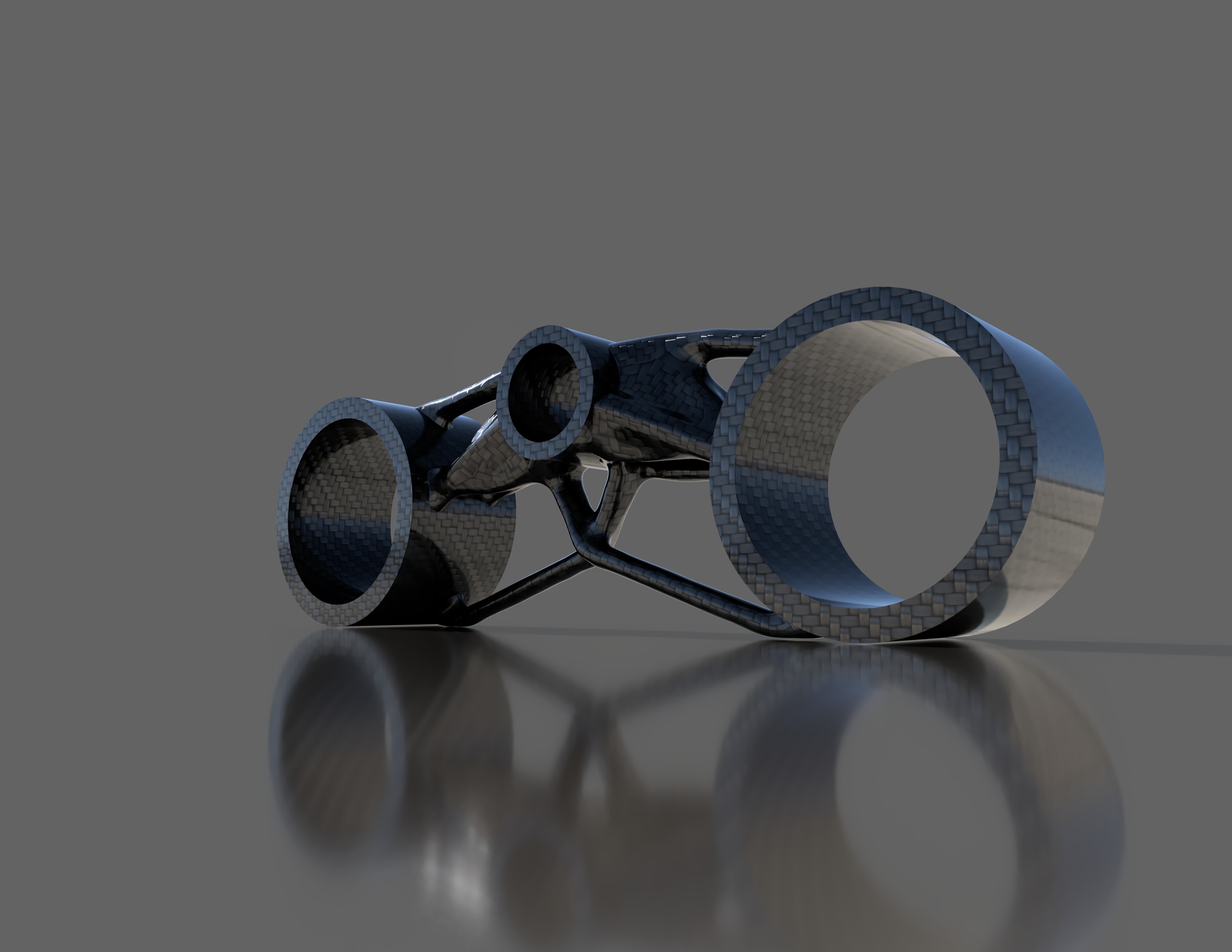

Motorcycle Triple Clamp

Generative Design

2024

2024

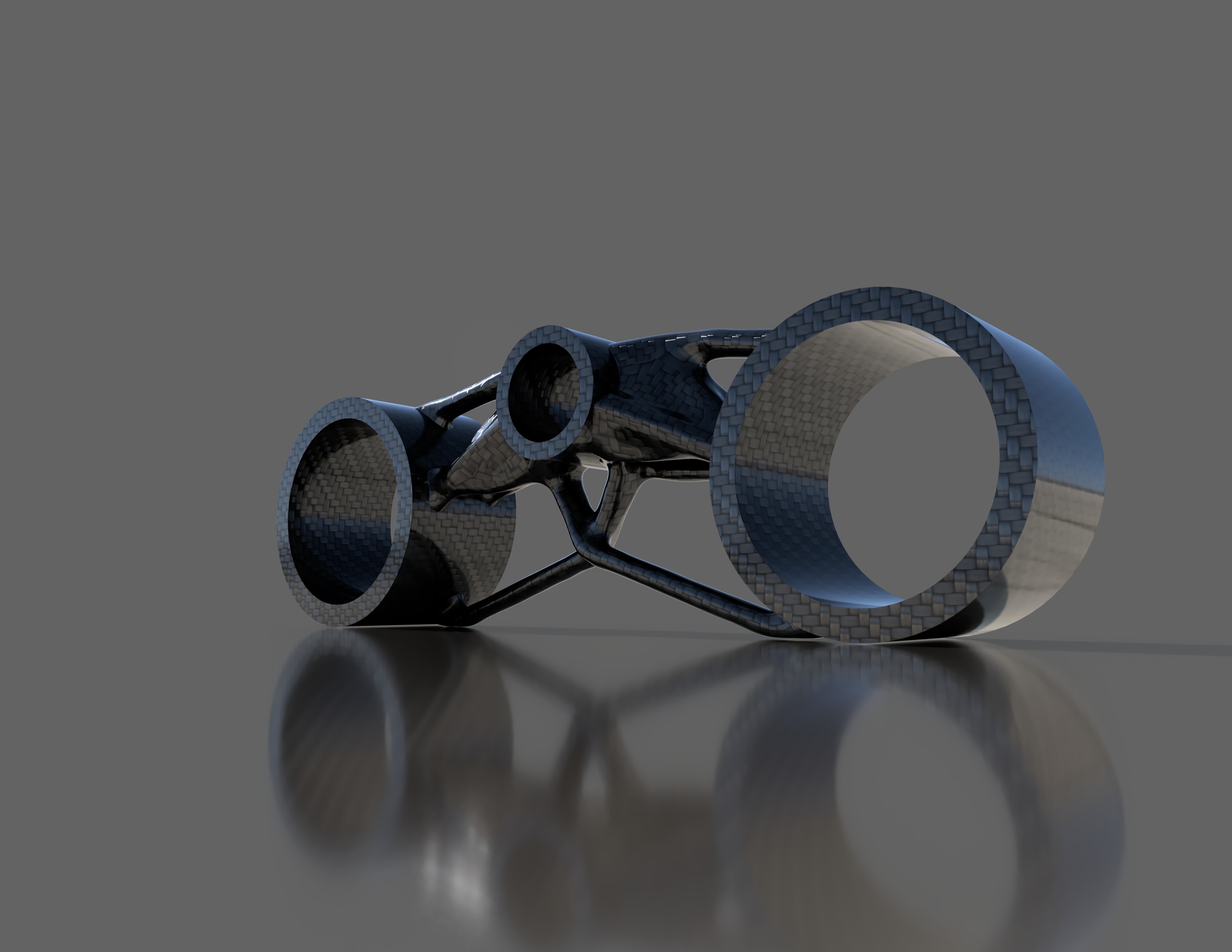

Motorcycle Triple Clamp

Generative Design

2024

2024

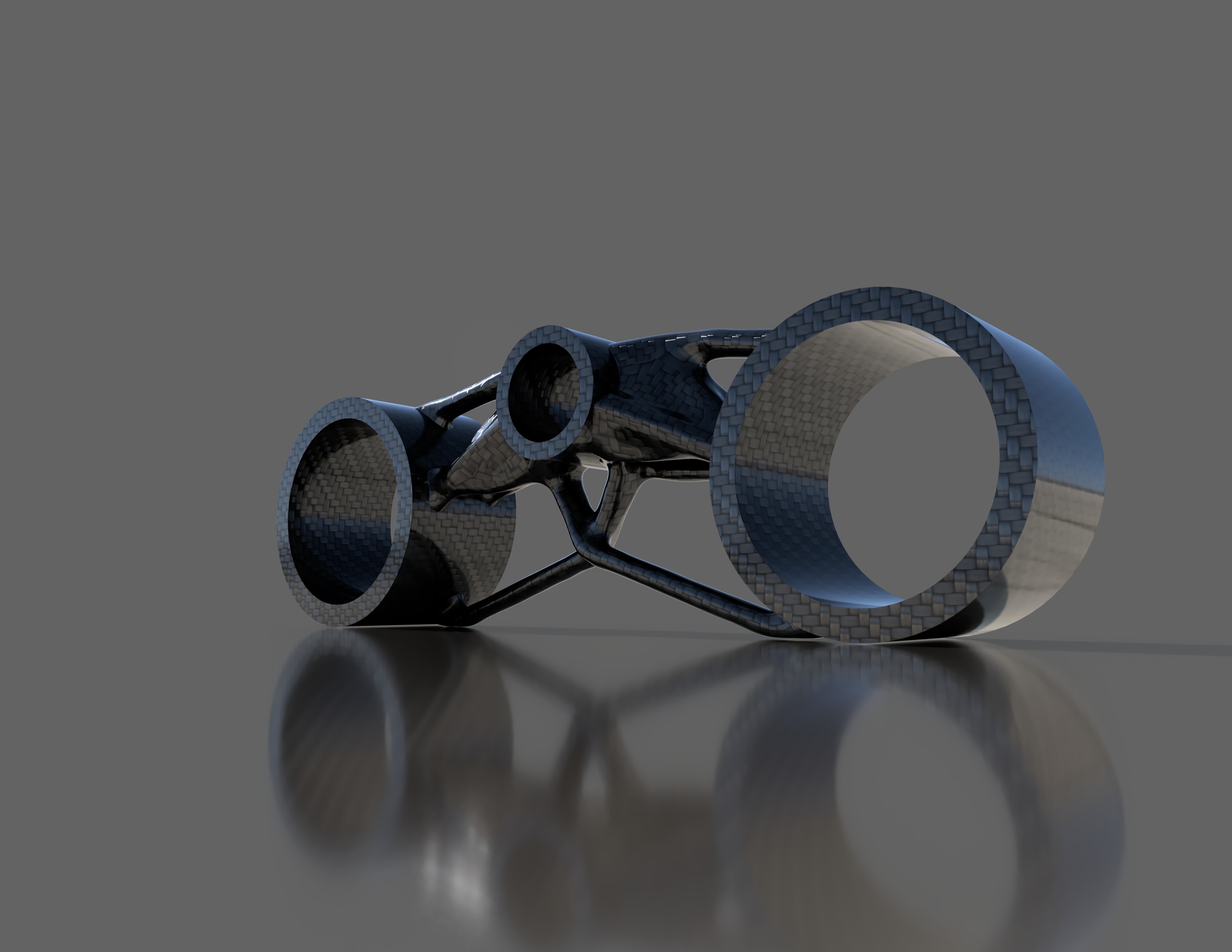

Motorcycle Triple Clamp

Generative Design

2024

2024

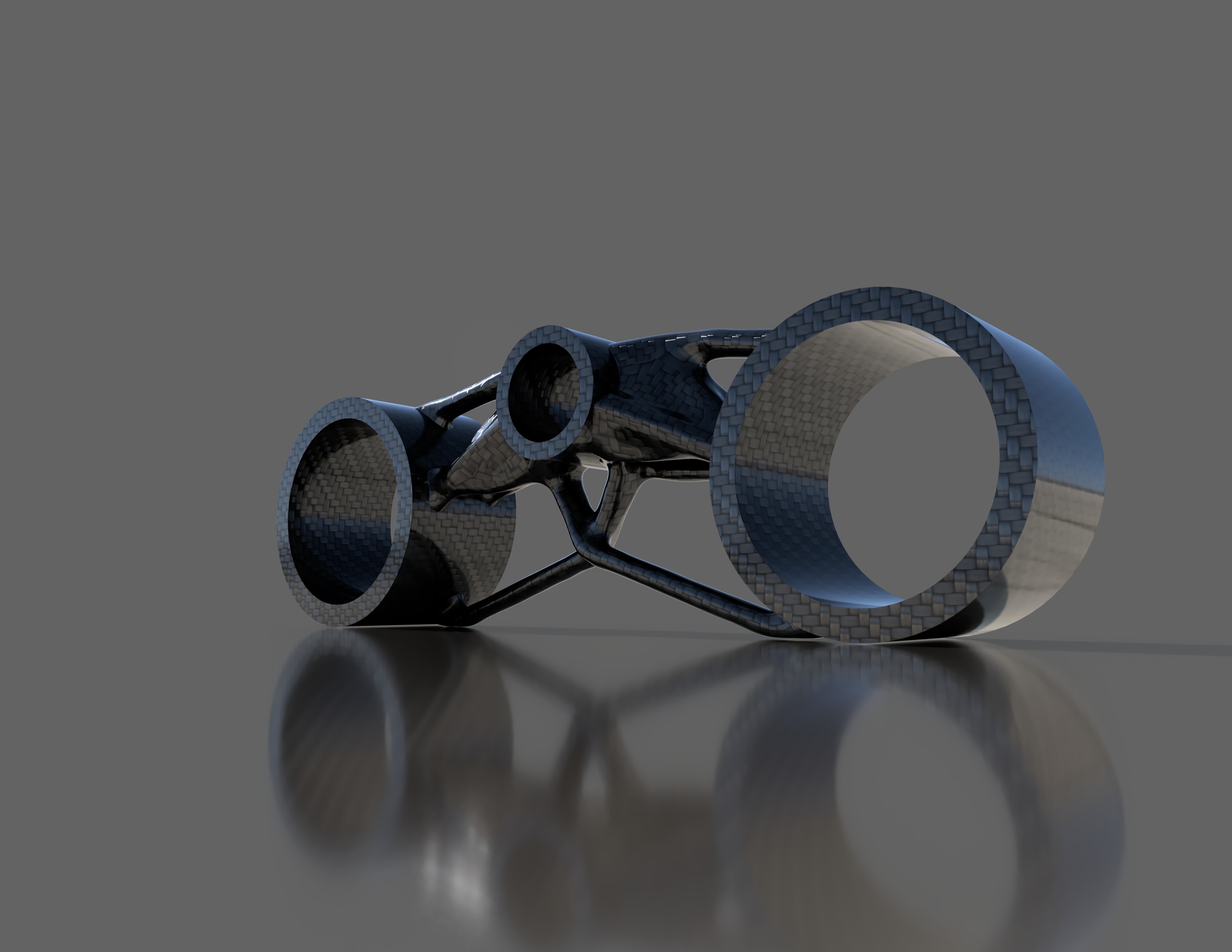

Motorcycle Triple Clamp

Generative Design

2024

2024

Skate & Rail Assembly

Designing & Simulation

2025

2025

Skate & Rail Assembly

Designing & Simulation

2025

2025

Skate & Rail Assembly

Designing & Simulation

2025

2025

Skate & Rail Assembly

Designing & Simulation

2025

2025

©2024 MANDRO DESIGN

GO BACK TO TOP

©2024 MANDRO DESIGN

GO BACK TO TOP